US

METRIC

772G

KEY SPECS

- Engine Model Cat® C18 ACERT™

- Rated Engine Speed 1800r/min

- Gross Power - SAE J1995:2014 446kW

OVERVIEW

FEATURES AT A GLANCE

Performance

Cat diesel engines are built to the highest quality standards with tight tolerances and proven piston, camshaft, engine block, and fuel system designs for excellent performance and life.

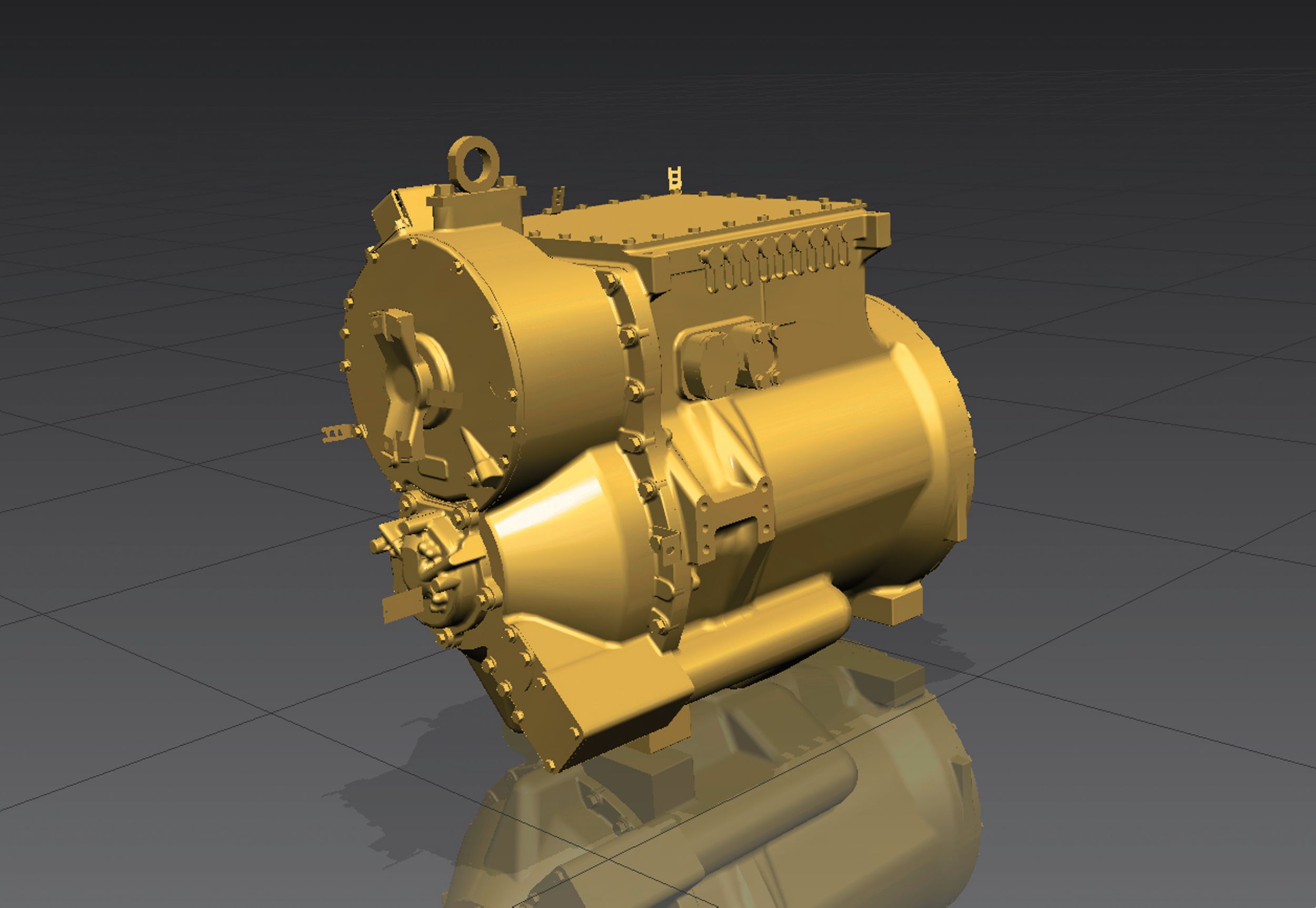

![]() The Cat C18 ACERT is an in-line 6-cylinder diesel engine used in both Cat equipment and in heavy-duty on-highway trucks. Designed, manufactured, and built by Caterpillar, this engine offers the following customer advantages:

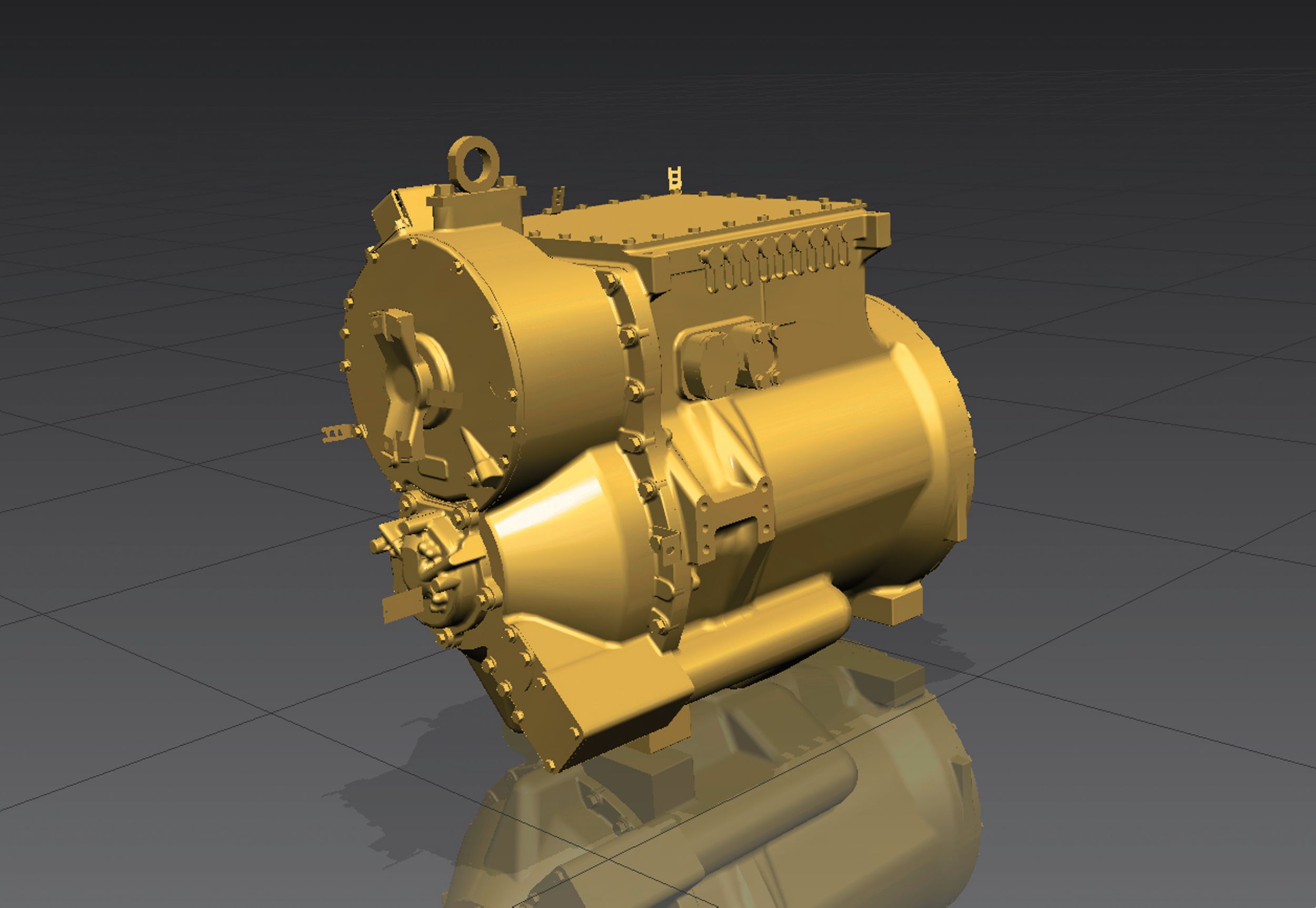

The Cat C18 ACERT is an in-line 6-cylinder diesel engine used in both Cat equipment and in heavy-duty on-highway trucks. Designed, manufactured, and built by Caterpillar, this engine offers the following customer advantages:![]() The Cat planetary power shift transmission is an automatic, 7-speed transmission built for heavy-duty, off-road applications including those with long, uphill grades. This transmission is managed with APECS, a strategy that provides an exceptionally smooth ride and allows power to carry through the shift points for excellent performance and speed on grades. In addition to delivering a quick and responsive truck, APECS is managing clutch pressures for long-life reliability.

The Cat planetary power shift transmission is an automatic, 7-speed transmission built for heavy-duty, off-road applications including those with long, uphill grades. This transmission is managed with APECS, a strategy that provides an exceptionally smooth ride and allows power to carry through the shift points for excellent performance and speed on grades. In addition to delivering a quick and responsive truck, APECS is managing clutch pressures for long-life reliability.

With its Cat power train components running in 7th gear, the 772G has a top speed of 79.7 km/h (49.5 mph).

With its Cat power train components running in 7th gear, the 772G has a top speed of 79.7 km/h (49.5 mph).

![]()

- Gross power (SAE J1995) 446 kW (598 hp)

- Net Power (SAE J1349) 415 kW (557 hp)

- Rated engine speed of 1,800 rpm

- Altitude capability to 3048 m (10,000 ft)

- Precise tolerances support greater combustion pressures and more work per unit of fuel

- A water-cooled, waste-gated turbocharger with titanium wheel offers long-life and excellent performance

- Electronically controlled fuel maps and torque curves are integrated specifically for the 772G

- Precise fuel injection using Mechanically Actuated Fuel Injection (MEUI™)

- Low pressure fuel lines up to the injectors

- 500 hour engine oil filter life under normal operating conditions

- Noise and vibration reduction for smooth operation and component life

- Available as either U.S. EPA Tier 2/EU Stage II equivalent OR Tier 3/Stage IIIA equivalent

With its Cat power train components running in 7th gear, the 772G has a top speed of 79.7 km/h (49.5 mph).

With its Cat power train components running in 7th gear, the 772G has a top speed of 79.7 km/h (49.5 mph).

Fuel Saving Strategies

Standard fuel economy is switch activated from within the cab. This economy mode works by reducing engine power. Customers can adjust the savings by reducing the power output of the truck by 0.5 to 15 percent.

![]() This economy mode uses on-board sensors and electronics to find opportunities to reduce power based on steady state speed. Customers will set a productivity threshold that the truck should stay above. The truck will regulate the power level based on the haul profile and may change the power of the truck several times in one haul.

This economy mode uses on-board sensors and electronics to find opportunities to reduce power based on steady state speed. Customers will set a productivity threshold that the truck should stay above. The truck will regulate the power level based on the haul profile and may change the power of the truck several times in one haul.

![]() Auto Neutral Idle can have a measureable impact on fuel savings. It works by placing the truck in a neutral state if the operator has been idle in a forward gear with the brake or retarder applied. The truck will automatically resume the forward gear when the brake is released or the throttle is applied.

Auto Neutral Idle can have a measureable impact on fuel savings. It works by placing the truck in a neutral state if the operator has been idle in a forward gear with the brake or retarder applied. The truck will automatically resume the forward gear when the brake is released or the throttle is applied.

![]() This feature must be activated by the customer. If engaged, the truck will warn the operator that it is about to shutdown after a prolonged period of idling in “Park.” Customers can set the idle time limit. When the time limit is reached, the truck will shut off the engine.

This feature must be activated by the customer. If engaged, the truck will warn the operator that it is about to shutdown after a prolonged period of idling in “Park.” Customers can set the idle time limit. When the time limit is reached, the truck will shut off the engine.

![]() Speed limiting is a new feature for G Series trucks and is offered as an alternative to gear limiting. It offers customers both fuel saving and component wear benefits. Speed limiting allows the truck to find the most fuel efficient gear and engine speed while traveling at a set limit. Speed limiting will also work with Automatic Retarding Control (ARC).

Speed limiting is a new feature for G Series trucks and is offered as an alternative to gear limiting. It offers customers both fuel saving and component wear benefits. Speed limiting allows the truck to find the most fuel efficient gear and engine speed while traveling at a set limit. Speed limiting will also work with Automatic Retarding Control (ARC).

![]() With its APECS transmission strategy, G Series trucks are carrying more torque and throttle through the shifts. The fuel benefit comes from recovering quickly during shifts and carrying more momentum up grades.

With its APECS transmission strategy, G Series trucks are carrying more torque and throttle through the shifts. The fuel benefit comes from recovering quickly during shifts and carrying more momentum up grades.

![]()

Brake Performance

An important differentiator for Cat trucks is their outstanding brake performance. The design principle is one of long-life and excellent performance in quarry, mine, and earthmoving applications.

![]() Cat trucks are equipped with hydraulically actuated, rear brakes and caliper-disc front brakes. Each truck offers primary service brakes, hydraulic retarding, and a parking brake.

Cat trucks are equipped with hydraulically actuated, rear brakes and caliper-disc front brakes. Each truck offers primary service brakes, hydraulic retarding, and a parking brake.

Each truck offers primary service brakes, hydraulic retarding and a parking brake.![]() Two hydraulic accumulators provide the pressure required for the service brakes. The second accumulator acts as a back up. On the rear axle, the oil-cooled, multiple disc brakes have large discs that provide fade resistant performance. The parking brake is applied on the rear brakes and can hold the machine, with rated load, on a 15 percent slope. In turn, the service brakes are designed to hold the truck on slopes of 20 percent.

Two hydraulic accumulators provide the pressure required for the service brakes. The second accumulator acts as a back up. On the rear axle, the oil-cooled, multiple disc brakes have large discs that provide fade resistant performance. The parking brake is applied on the rear brakes and can hold the machine, with rated load, on a 15 percent slope. In turn, the service brakes are designed to hold the truck on slopes of 20 percent.

![]() Automatic Retarding Control is standard on the 772G. This feature controls truck speed by automatically applying brake force when the engine exceeds a set rpm. Operators can adjust the engine speed between 1950 and 2200 rpm. This feature is important because it does the work of controlling truck speed on long, downhill hauls without constant input from the operator; it’s smooth for greater control and has a tendency to provide faster cycle times over manual retarding. As a precautionary feature, ARC will automatically engage to prevent engine overspeeding at any time during truck operation.

Automatic Retarding Control is standard on the 772G. This feature controls truck speed by automatically applying brake force when the engine exceeds a set rpm. Operators can adjust the engine speed between 1950 and 2200 rpm. This feature is important because it does the work of controlling truck speed on long, downhill hauls without constant input from the operator; it’s smooth for greater control and has a tendency to provide faster cycle times over manual retarding. As a precautionary feature, ARC will automatically engage to prevent engine overspeeding at any time during truck operation.

![]() Caterpillar offers an optional engine brake. This engine brake works with ARC to control speed on grade. By incorporating engine braking with Automatic Retarding, customers can reduce brake component wear and achieve faster cycle times.

Caterpillar offers an optional engine brake. This engine brake works with ARC to control speed on grade. By incorporating engine braking with Automatic Retarding, customers can reduce brake component wear and achieve faster cycle times.

![]()

Each truck offers primary service brakes, hydraulic retarding and a parking brake.

Traction Control System

If your ground conditions are wet or slippery, the 772G is equipped with Traction Control that engages quickly and effectively to control tires that are slipping.

![]() The system is steering sensitive to differentiate between turning or slipping, allowing the system to engage at slow speeds and much sooner in the slip.

The system is steering sensitive to differentiate between turning or slipping, allowing the system to engage at slow speeds and much sooner in the slip.

![]() Once the system is engaged, it responds quickly by using the hydraulically-applied service brakes, not the spring-applied secondary brake. TCS regains traction faster by instantly modulating braking and power between the two rear wheel groups keeping your haul trucks moving and productive.

Once the system is engaged, it responds quickly by using the hydraulically-applied service brakes, not the spring-applied secondary brake. TCS regains traction faster by instantly modulating braking and power between the two rear wheel groups keeping your haul trucks moving and productive.

![]() By reacting quickly and at slow speeds, tire life and cycle times both benefit.

By reacting quickly and at slow speeds, tire life and cycle times both benefit.

Note: TCS is optional on this machine.![]()

Note: TCS is optional on this machine.

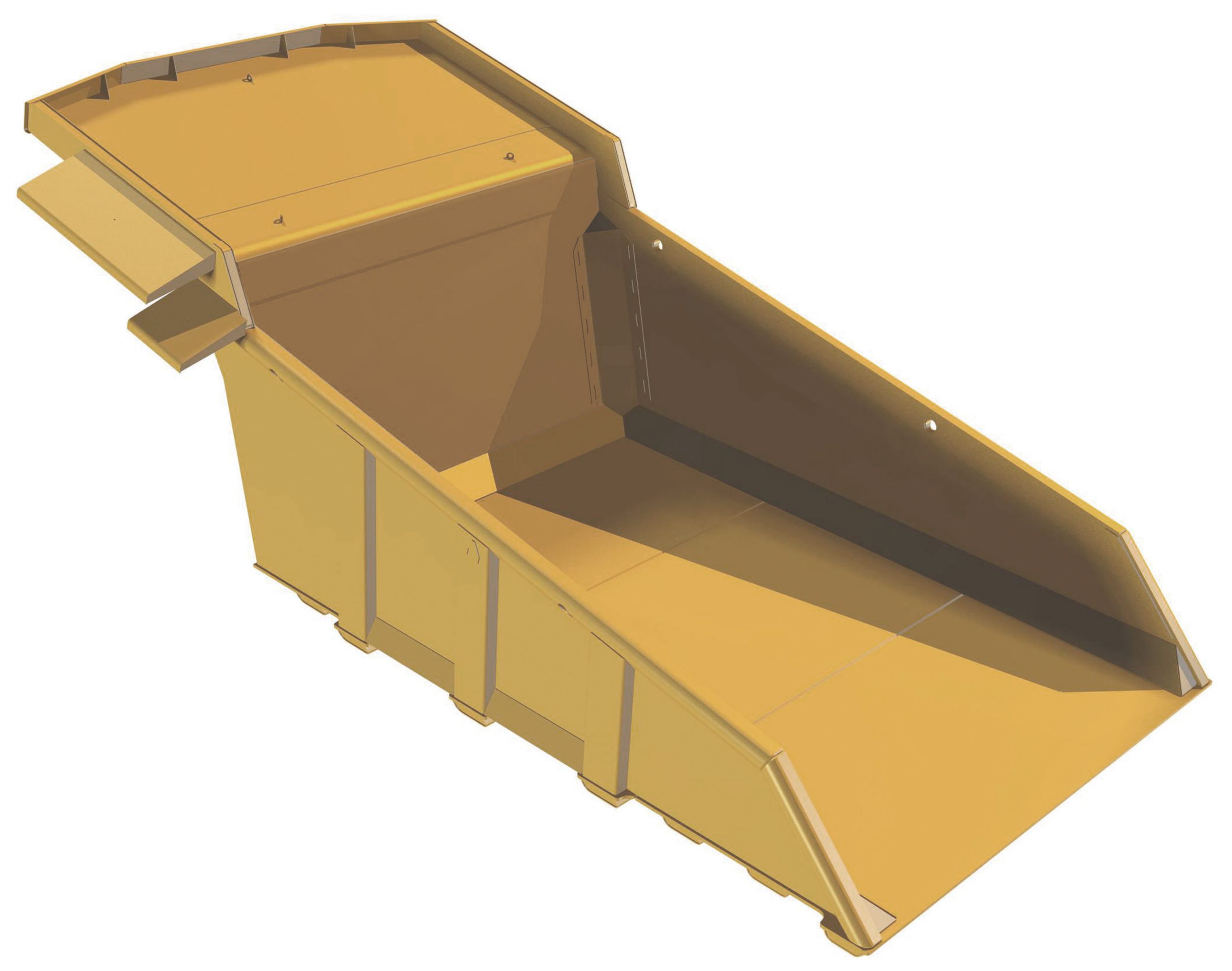

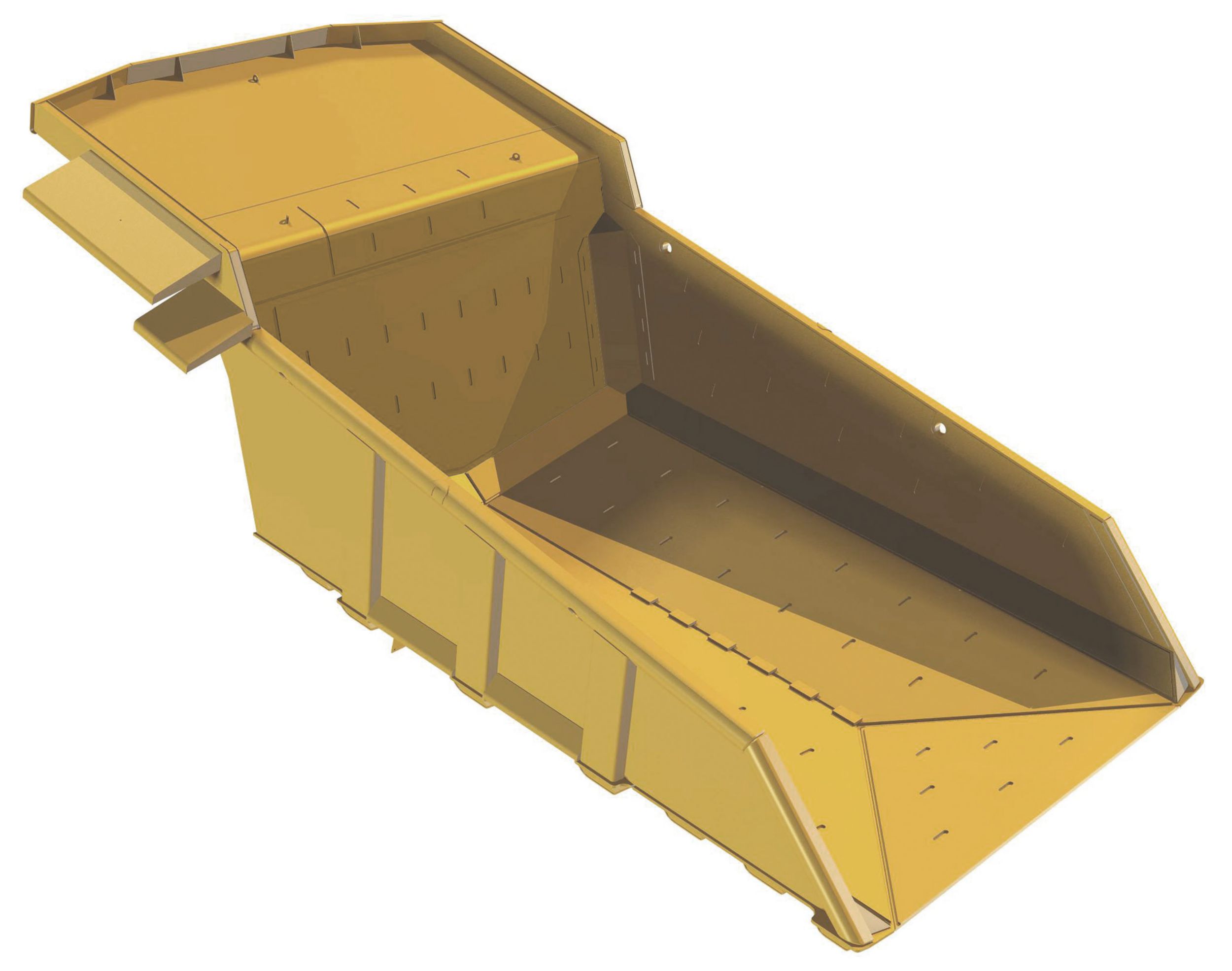

Truck Bodies

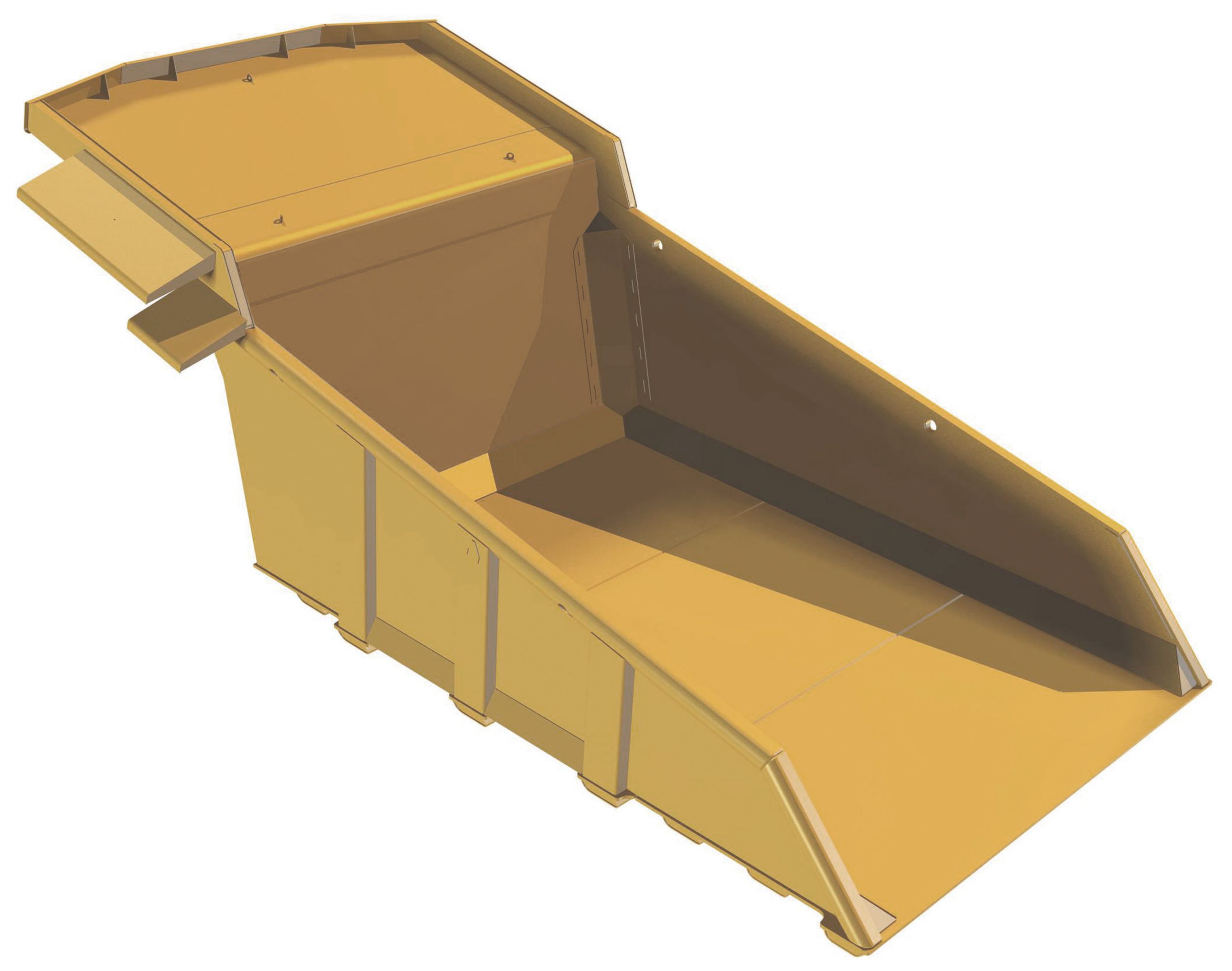

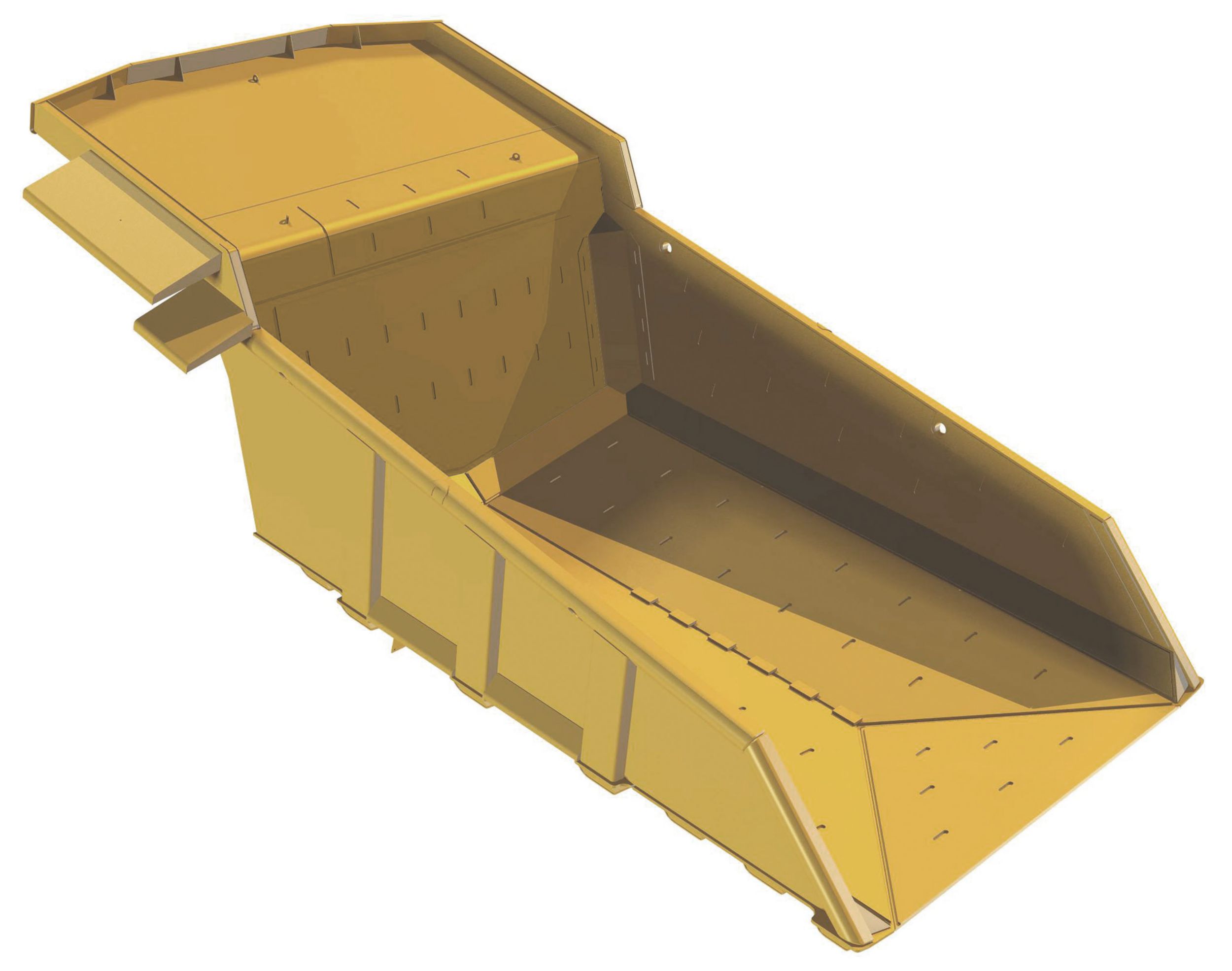

Caterpillar has body options to meet your material type and application needs. Cat truck bodies will last the life of the truck if properly configured, guarded, and maintained.

![]() Flat Floor and Dual Slope bodies are lined with 16 mm (0.62 in) of 400 Brinell Hardness Number (BNH) high-impact steel.

Flat Floor and Dual Slope bodies are lined with 16 mm (0.62 in) of 400 Brinell Hardness Number (BNH) high-impact steel.

Two floor types are available, Flat and Dual Slope.

Two floor types are available, Flat and Dual Slope.![]() Caterpillar offers a single, 16 mm (0.62 in) steel liner that can be added to the Flat Floor and Dual Slope bodies to protect against high impact and highly abrasive materials.

Caterpillar offers a single, 16 mm (0.62 in) steel liner that can be added to the Flat Floor and Dual Slope bodies to protect against high impact and highly abrasive materials.

Caterpillar offers a purpose-built Quarry body for soft limestone quarries. This body has a 25 mm (0.98 in), 400 BNH steel floor and does not require additional liners if kept in limestone.

Caterpillar offers a purpose-built Quarry body for soft limestone quarries. This body has a 25 mm (0.98 in), 400 BNH steel floor and does not require additional liners if kept in limestone.

![]() Customers who are loading extremely hard material that has high impact characteristics should consider a factory-installed rubber liner system. This system is intended for hard rock and should not be considered for machines that could be loaded with clay, cohesive material or hot material.

Customers who are loading extremely hard material that has high impact characteristics should consider a factory-installed rubber liner system. This system is intended for hard rock and should not be considered for machines that could be loaded with clay, cohesive material or hot material.

![]() Cat bodies are equipped to retain high-capacity loads for long hauls and to travel up steep grades; however, overloading a truck can negatively impact productivity, reduce tire life, and increase haul road maintenance costs.

Cat bodies are equipped to retain high-capacity loads for long hauls and to travel up steep grades; however, overloading a truck can negatively impact productivity, reduce tire life, and increase haul road maintenance costs.

![]() Caterpillar’s 10/10/20 Payload Policy is in place to help you maximize productivity with optimum component life and availability of your truck. Your Cat dealer can further explain the 10/10/20 policy. For optimum body life, Caterpillar recommends that 110% payloads occur no more than 10% of the time and that the average of all loads equal the target payload. Payload should never exceed 120% of target.

Caterpillar’s 10/10/20 Payload Policy is in place to help you maximize productivity with optimum component life and availability of your truck. Your Cat dealer can further explain the 10/10/20 policy. For optimum body life, Caterpillar recommends that 110% payloads occur no more than 10% of the time and that the average of all loads equal the target payload. Payload should never exceed 120% of target.

![]()

Two floor types are available, Flat and Dual Slope.

Two floor types are available, Flat and Dual Slope.- Flat Floor bodies are ideal for delivering product to a crusher; material unloads in a controlled manner.

- Dual Slope bodies center the load and keep it stable and retained on steeper grades.

Caterpillar offers a purpose-built Quarry body for soft limestone quarries. This body has a 25 mm (0.98 in), 400 BNH steel floor and does not require additional liners if kept in limestone.

Caterpillar offers a purpose-built Quarry body for soft limestone quarries. This body has a 25 mm (0.98 in), 400 BNH steel floor and does not require additional liners if kept in limestone.

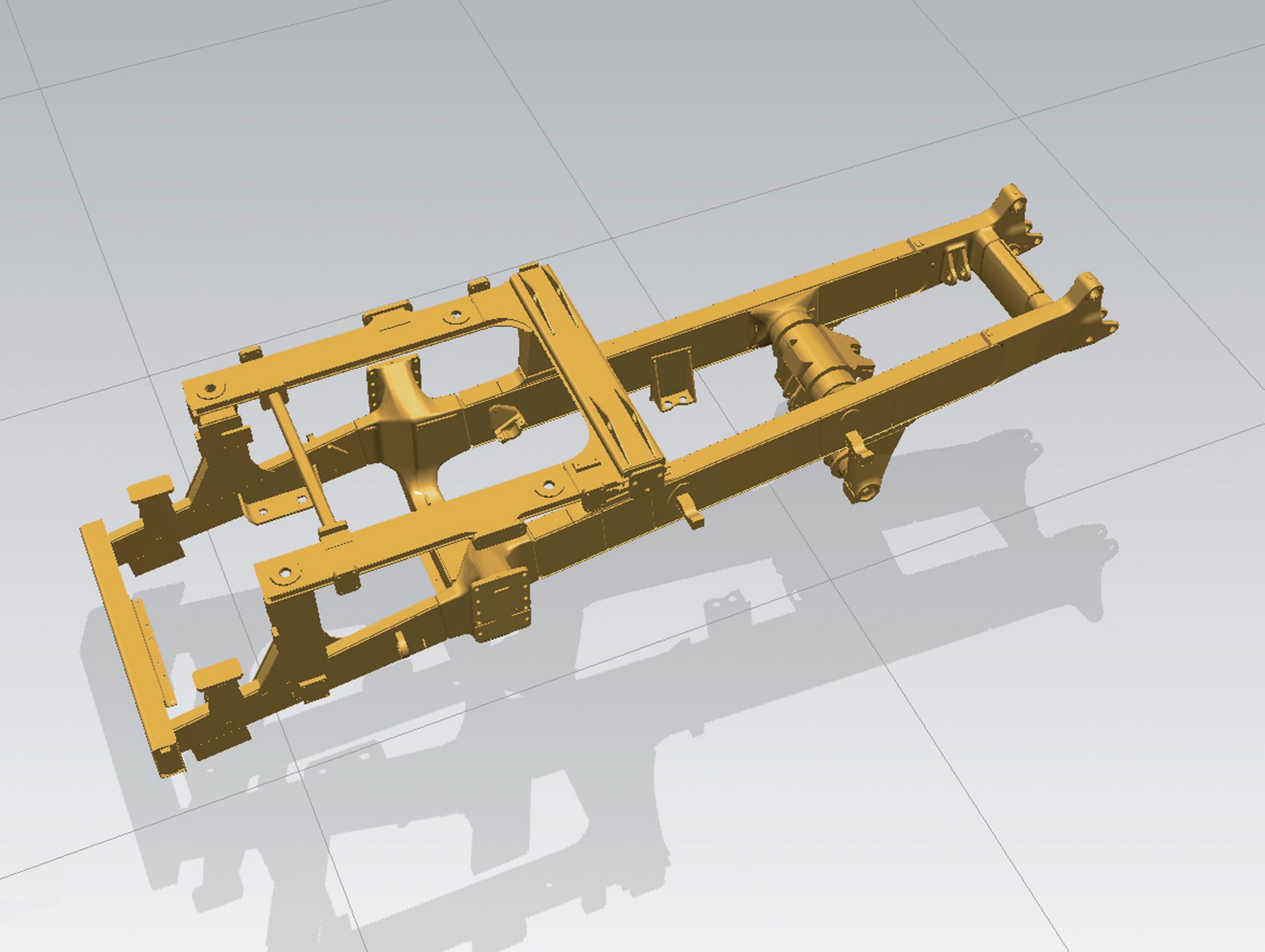

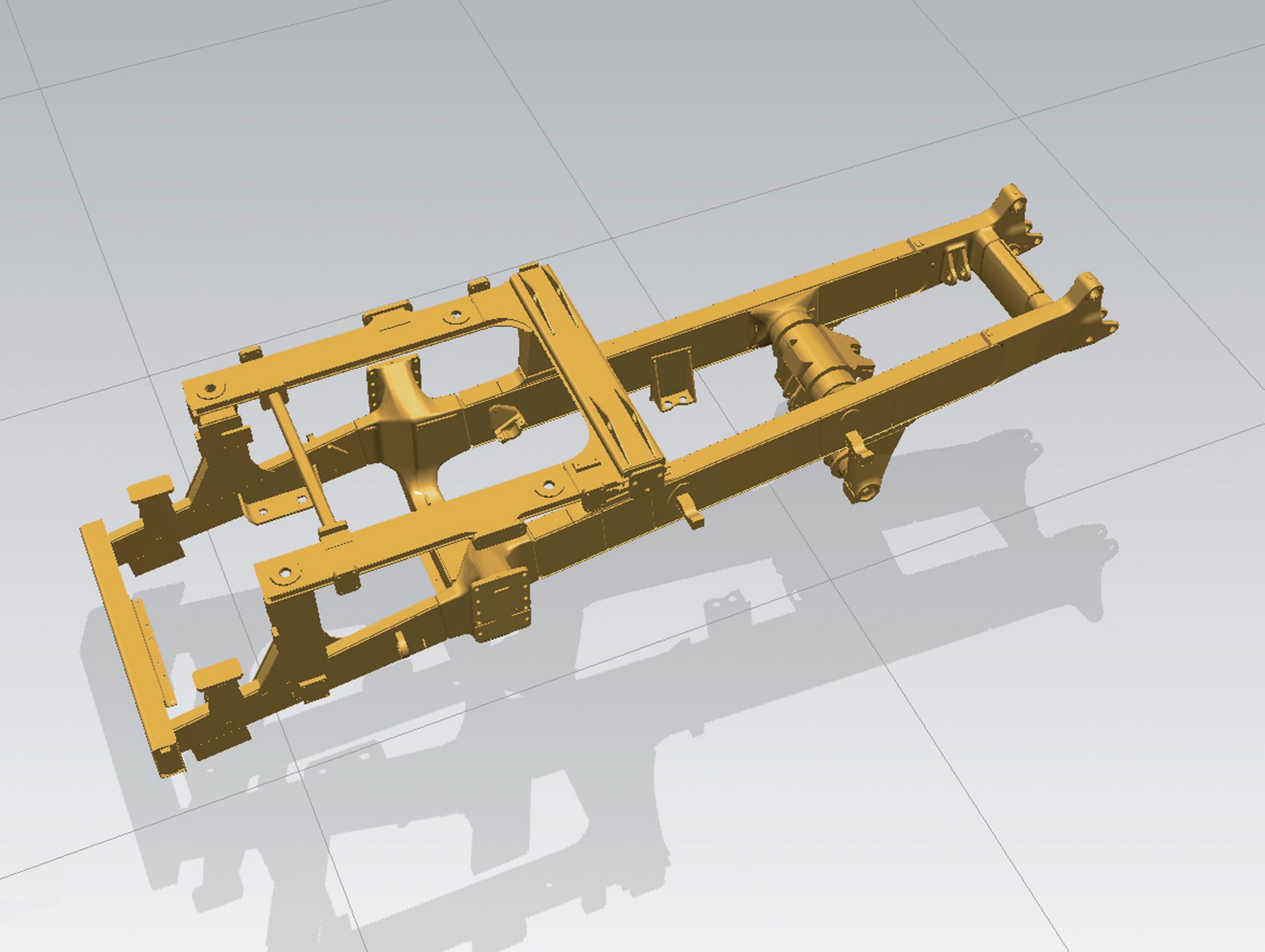

Structures

Cat trucks are known throughout the industry for reliable, long-life frames. Built for off-road maneuvering and haul road conditions, Caterpillar uses castings in high stress areas and box section construction to manage torsion-loading.

Mild steel is used for its tensile strength and ease of welding, an important feature in being able to make field repairs. The frames are built on a platform that rotates 360 degrees, allowing consistent, deeply-penetrating welds. Each frame is subject to quality and conformance testing prior to assembly.

Mild steel is used for its tensile strength and ease of welding, an important feature in being able to make field repairs. The frames are built on a platform that rotates 360 degrees, allowing consistent, deeply-penetrating welds. Each frame is subject to quality and conformance testing prior to assembly.

![]() The Cat suspension and steering design offers you the following benefits:

The Cat suspension and steering design offers you the following benefits:

Mild steel is used for its tensile strength and ease of welding, an important feature in being able to make field repairs. The frames are built on a platform that rotates 360 degrees, allowing consistent, deeply-penetrating welds. Each frame is subject to quality and conformance testing prior to assembly.

Mild steel is used for its tensile strength and ease of welding, an important feature in being able to make field repairs. The frames are built on a platform that rotates 360 degrees, allowing consistent, deeply-penetrating welds. Each frame is subject to quality and conformance testing prior to assembly.

- Excellent ride quality - empty or loaded

- The front struts act as a king pin for long-life in off-road applications

- Nitrogen over oil strut design

- Simple yet rugged steering system that maintains proper tire alignment

- Inverted rear cylinders stay cleaner longer; reduce shock loading to the frame

Operator Experience

Both optional and standard features like those described here can increase the productivity of your operators:

![]()

- Optional automatic temperature control

- Optional left side power window

- Optional heat and air conditioning

- Low-effort access system

- Optional Cat Comfort Series III seat

- Sound suppression

- Standard Rollover/Falling Object Protection in compliance with ISO 3471:2008 ROPS criteria and ISO 3449:2005 Level II FOPS criteria

- Optional camera system for visibility behind the machine

- Automatic Retarding Control (ARC)

- Trainer seat

- Emergency egress through right side window

- Optional fluid level monitoring

- An optional Advisor display delivers machine information to the operator

- Standard Automatic Retarding Control (ARC)

- Standard Traction Control System (TCS)

- Speed limiting on the haul

- Excellent visibility to the loading tool

- Primary service brakes, secondary braking

- Slope holding capability on grades up to 20%

- Body up speed limiting while unloading

Information and Monitoring

The Cat gauge cluster is a standard display found in the cab. It displays real-time machine performance and operating data. An optional Advisor display allows a greater degree of communication with the truck and from the truck.

![]() VIMS is the Cat Vital Information Management System. This information management system is integrated into the engine, chassis, and all other electronic controllers to deliver valuable information on machine health and productivity. This system uses the Advisor Display to communicate data. VIMS reports provide histograms on truck operation, payloads, and cycle times. These reports can help you manage your fleet, site, and provide production levels.

VIMS is the Cat Vital Information Management System. This information management system is integrated into the engine, chassis, and all other electronic controllers to deliver valuable information on machine health and productivity. This system uses the Advisor Display to communicate data. VIMS reports provide histograms on truck operation, payloads, and cycle times. These reports can help you manage your fleet, site, and provide production levels.

Cat Product Link™ allows remote monitoring of equipment to improve overall fleet management effectiveness. Events and diagnostic codes as well as hours, fuel, idle time, and other detailed information are transmitted to a secure web-based application – VisionLink®. VisionLink includes powerful tools to convey information to our customers and their dealers, including mapping, working and idle time, fuel level and more. Product Link is not available in all areas, please check with your local Cat dealer.

Cat Product Link™ allows remote monitoring of equipment to improve overall fleet management effectiveness. Events and diagnostic codes as well as hours, fuel, idle time, and other detailed information are transmitted to a secure web-based application – VisionLink®. VisionLink includes powerful tools to convey information to our customers and their dealers, including mapping, working and idle time, fuel level and more. Product Link is not available in all areas, please check with your local Cat dealer.

The Cat Truck Production Management System is an optional tool to help you manage your operations. Indicator lights on the truck tell the loader operator they have additional loads to put on the truck (solid green light) as well as one last pass (blinking red light) and then when the truck is loaded (solid red light). Truck Production Management System will track loads, cycle times, and payload data – up to 2,400 cycles – and reports out through the on-board display or VIMS. The system takes two payload measurements; the first after loading and a second as the truck pulls away in 2nd gear. This is done for greater accuracy.

The Cat Truck Production Management System is an optional tool to help you manage your operations. Indicator lights on the truck tell the loader operator they have additional loads to put on the truck (solid green light) as well as one last pass (blinking red light) and then when the truck is loaded (solid red light). Truck Production Management System will track loads, cycle times, and payload data – up to 2,400 cycles – and reports out through the on-board display or VIMS. The system takes two payload measurements; the first after loading and a second as the truck pulls away in 2nd gear. This is done for greater accuracy.

TKPH/TMPH stands for Ton Kilometer per Hour/Ton Mile per Hour. This optional feature is an on-board tool that takes the manufacturer’s tire rating and in real time, compares it with ambient temperature, payload, and truck speed. If the tires are calculated to be approaching their temperature limits, the operator will receive a warning. If the tire temperature condition becomes critical, your truck can be set up to automatically reduce (or limit) speed to allow cooling.

TKPH/TMPH stands for Ton Kilometer per Hour/Ton Mile per Hour. This optional feature is an on-board tool that takes the manufacturer’s tire rating and in real time, compares it with ambient temperature, payload, and truck speed. If the tires are calculated to be approaching their temperature limits, the operator will receive a warning. If the tire temperature condition becomes critical, your truck can be set up to automatically reduce (or limit) speed to allow cooling.

![]()

Cat Product Link™ allows remote monitoring of equipment to improve overall fleet management effectiveness. Events and diagnostic codes as well as hours, fuel, idle time, and other detailed information are transmitted to a secure web-based application – VisionLink®. VisionLink includes powerful tools to convey information to our customers and their dealers, including mapping, working and idle time, fuel level and more. Product Link is not available in all areas, please check with your local Cat dealer.

Cat Product Link™ allows remote monitoring of equipment to improve overall fleet management effectiveness. Events and diagnostic codes as well as hours, fuel, idle time, and other detailed information are transmitted to a secure web-based application – VisionLink®. VisionLink includes powerful tools to convey information to our customers and their dealers, including mapping, working and idle time, fuel level and more. Product Link is not available in all areas, please check with your local Cat dealer.

The Cat Truck Production Management System is an optional tool to help you manage your operations. Indicator lights on the truck tell the loader operator they have additional loads to put on the truck (solid green light) as well as one last pass (blinking red light) and then when the truck is loaded (solid red light). Truck Production Management System will track loads, cycle times, and payload data – up to 2,400 cycles – and reports out through the on-board display or VIMS. The system takes two payload measurements; the first after loading and a second as the truck pulls away in 2nd gear. This is done for greater accuracy.

The Cat Truck Production Management System is an optional tool to help you manage your operations. Indicator lights on the truck tell the loader operator they have additional loads to put on the truck (solid green light) as well as one last pass (blinking red light) and then when the truck is loaded (solid red light). Truck Production Management System will track loads, cycle times, and payload data – up to 2,400 cycles – and reports out through the on-board display or VIMS. The system takes two payload measurements; the first after loading and a second as the truck pulls away in 2nd gear. This is done for greater accuracy.

TKPH/TMPH stands for Ton Kilometer per Hour/Ton Mile per Hour. This optional feature is an on-board tool that takes the manufacturer’s tire rating and in real time, compares it with ambient temperature, payload, and truck speed. If the tires are calculated to be approaching their temperature limits, the operator will receive a warning. If the tire temperature condition becomes critical, your truck can be set up to automatically reduce (or limit) speed to allow cooling.

TKPH/TMPH stands for Ton Kilometer per Hour/Ton Mile per Hour. This optional feature is an on-board tool that takes the manufacturer’s tire rating and in real time, compares it with ambient temperature, payload, and truck speed. If the tires are calculated to be approaching their temperature limits, the operator will receive a warning. If the tire temperature condition becomes critical, your truck can be set up to automatically reduce (or limit) speed to allow cooling.

Simple Service

Your Cat G Series truck is designed to provide operators and technicians with easy access to common service points like engine lockout, machine system lockout, fluid level sight gauges, grease fittings, and access to the engine for regularly scheduled maintenance.

- Engine oil and filter change interval is 500 hours under normal operating conditions

- Hydraulic filters have a 1,000 hour life under normal operating conditions

- VIMS™ trend analysis can track machine health and operation

- A brake wear indicator is standard

- Automatic lubrication is available as optional equipment

- Fuses and breakers are easy to access and organized for simple service

- The radiator and cooling cores are aluminum and modular offering easy cleaning or replacement

- Oil sampling ports are provided for quick and clean collection for analysis

- Fuel system features electric priming

- Fast fill fuel is optional

Customer Support

Cat dealers offer a wide range of solutions, services, and products that help you lower costs, enhance productivity, and manage your operation more efficiently. Support goes far beyond parts and service. From the time you select a piece of Cat equipment until the day you rebuild, trade or sell it, your Cat dealer will stand behind your business with solutions that range from operator training to jobsite solutions. For more information on how Caterpillar and its dealers can support you, please visit the following web sites:

![]() www.cat.com/safety

www.cat.com/safety

![]() www.Mining.cat.com

www.Mining.cat.com

![]() www.Caterpillar.com

www.Caterpillar.com

![]() www.Cat.com

www.Cat.com

![]()

Safety and Sustainability

At Caterpillar, safety is embedded in our culture. As we design a truck, we take the safety of the operator and personnel working on the ground very seriously.![]() We bring about progress for our communities by producing aggregate and minerals for new roads, bridges, and energy. Cat trucks are being designed to do this work with less of an impact on the environment, by being quiet, using less fuel, emitting fewer emissions, and incorporating solid, long-life designs and components.

We bring about progress for our communities by producing aggregate and minerals for new roads, bridges, and energy. Cat trucks are being designed to do this work with less of an impact on the environment, by being quiet, using less fuel, emitting fewer emissions, and incorporating solid, long-life designs and components.

![]()

- We incorporate a rollover protected and falling object protected cab structure that supports the weight of the machine and its load.

- We design our trucks for easy access with handrails for three-points of contact and non-skid step surfaces with a tread plate that sheds material and provides excellent traction.

- Optional fluid level monitoring from the cab.

- Our cab offers excellent visibility around the machine with mirror choices and an optional camera system for 115 degrees of visibility behind the truck.

- Our truck brakes are designed for long-life without fading and include a brake wear indicator.

- Speed limiting to regulate haul speeds.

- Optional Traction Control works to return traction on slippery ground.

- Customers can lock out machine steering and secure the body in the up position during service.

SPECIFICATIONS

- Engine Model Cat® C18 ACERT™

- Rated Engine Speed 1800r/min

- Gross Power - SAE J1995:2014 446kW

- Net Power - SAE J1349:2011 415kW

- Net Power - ISO 9249 421kW

- Net Power - 80/1269/EEC 421kW

- Engine Power - ISO 14396 435kW

- Net Torque - SAE J1349 2551N·m

- Number of Cylinders 6

- Bore 145mm

- Stroke 183mm

- Displacement 18.1l

- Note (1) Power rating applies at 1,800 rpm when tested under the specified condition for the specified standard.

- Note (2) Ratings based on SAE J1995 standard air conditions of 25° C (77° F) and 100 kPa (29.61 Hg) barometer. Power based on fuel having API gravity of 35 at 16° C (60° F) and an LHV of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F).

- Note (3) No engine derating required up to 3000 m (9,843 ft) altitude.

- Note (4) Available as Tier 3/Stage IIIA equivalent, OR Tier 2/Stage II equivalent emission standards.

- Note (5) Meets China Nonroad Stage III emission standards equivalent to U.S. EPA Tier 3 or U.S. EPA Tier 2.

- Target Gross Machine Operating Weight 82100kg

- Chassis Weight 26863kg

- Body Weight 8030kg

- Note (1) Chassis weight with 100% fuel, hoist, body mounting group, rims and tires.

- Note (2) Body weight is the standard Dual Slope body with no liner and will vary depending on configuration.

- Nominal Payload Class (100%) 47.2t

- Top Speed - Loaded 71.7km/h

- Target Payload (100%) 47.2t

- Maximum Working Payload (110%) 51.9t

- Maximum Allowable Payload (120%)* 56.6t

- Body Capacity (SAE 2:1)** 31.2m³

- Note *Refer to the Caterpillar 10/10/20 Payload Policy for maximum gross machine weight limitations.

- Note (1) **ISO 6483:1980.

- Note (2) Capacity with Dual Slope body with no liner.

- Forward - 1 12.9km/h

- Forward - 2 17.7km/h

- Forward - 3 24km/h

- Forward - 4 32.2km/h

- Forward - 5 43.6km/h

- Forward - 6 58.7km/h

- Forward - 7 79.7km/h

- Reverse 16.9km/h

- Note Maximum travel speeds with standard 21.00R33 (E4) tires.

- Differential Ratio 2.74:1

- Planetary Ratio 4.80:1

- Total Reduction Ratio 13.14:1

- Brake Surface - Front 1395cm²

- Brake Surface - Rear 50281cm²

- Brake Standards ISO 3450:2011

- Pump Flow - High Idle 413l/min

- Relief Valve Setting - Raise 18950kPa

- Relief Valve Setting - Lower 3450kPa

- Body Raise Time - High Idle 8s

- Body Lower Time - Float 10s

- Body Power Down - High Idle 10s

- Struck 23.9m³

- Heaped (SAE 2:1)* 31.2m³

- Note (1) Contact your local Cat dealer for body recommendation.

- Note (2) *ISO 6483:1980.

- Struck 23.9m³

- Heaped (SAE 2:1)* 31.3m³

- Note (1) Contact your local Cat dealer for body recommendation.

- Note (2) *ISO 6483:1980.

- Front Axle - Empty 51.4%

- Front Axle - Loaded 34.2%

- Rear Axle - Empty 48.6%

- Rear Axle - Loaded 65.8%

- Empty Loaded Cylinder Stroke Front 234mm

- Empty Loaded Cylinder Stroke Rear 149mm

- Rear Axle - Oscillation 8.9°

- Fuel Tank 530l

- Cooling System 125l

- Crankcase 64l

- Differential - Final Drives 151l

- Steering Tank 55l

- Steering System - Includes Tank 74l

- Brake/Hoist Hydraulic Tank 176l

- Brake Hoist System 227l

- Torque Converter - Transmission System 72l

- Steering Standards SAE J1511 FEB94 ISO 5010:2007

- Steer Angle 40.5°

- Turning Diameter - Front 17.6m

- Turning Circle - Clearance Diameter 20.3m

- Standard Tire 21.00R33 (E4)

- Note (1) Productive capabilities of the 772G truck are such that, under certain job conditions, TKPH (TMPH) capabilities of standard or optional tires could be exceeded and, therefore, limit production.

- Note (2) Caterpillar recommends the customer evaluates all job conditions and consults the tire manufacturer for proper tire selection.

- FOPS Standards Falling Objects Protective Structure (FOPS) meets ISO 3449:2005 Level II FOPS criteria.

- ROPS Standards Rollover Protective Structure (ROPS) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria.

- Inside Body Depth - Maximum 1747mm

- Rear Axle - Tail 2598mm

- Centerline Front Tire Width 3165mm

- Centerline of Rear Dual Tire Width 2652mm

- Ground Clearance 695mm

- Operating Width 4780mm

- Front Canopy Height 4265mm

- Loading Height - Empty 3639mm

- Inside Body Length 5781mm

- Engine Guard Clearance 711mm

- Outside Body Width 3931mm

- Overall Length 8808mm

- Overall Height - Body Raised 8357mm

- Overall Tire Width 3927mm

- Dump Clearance 551mm

- Inside Body Width 3642mm

- Height - Top of ROPS 4012mm

- Rear Axle - Clearance 591mm

- Wheel Base 3960mm

- Overall Body Length 8172mm

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS