How Connected Assets Are Revolutionising Mining and Construction

Explore how IoT and connected assets are revolutionising mining and construction through smarter, safer, and more efficient operations.

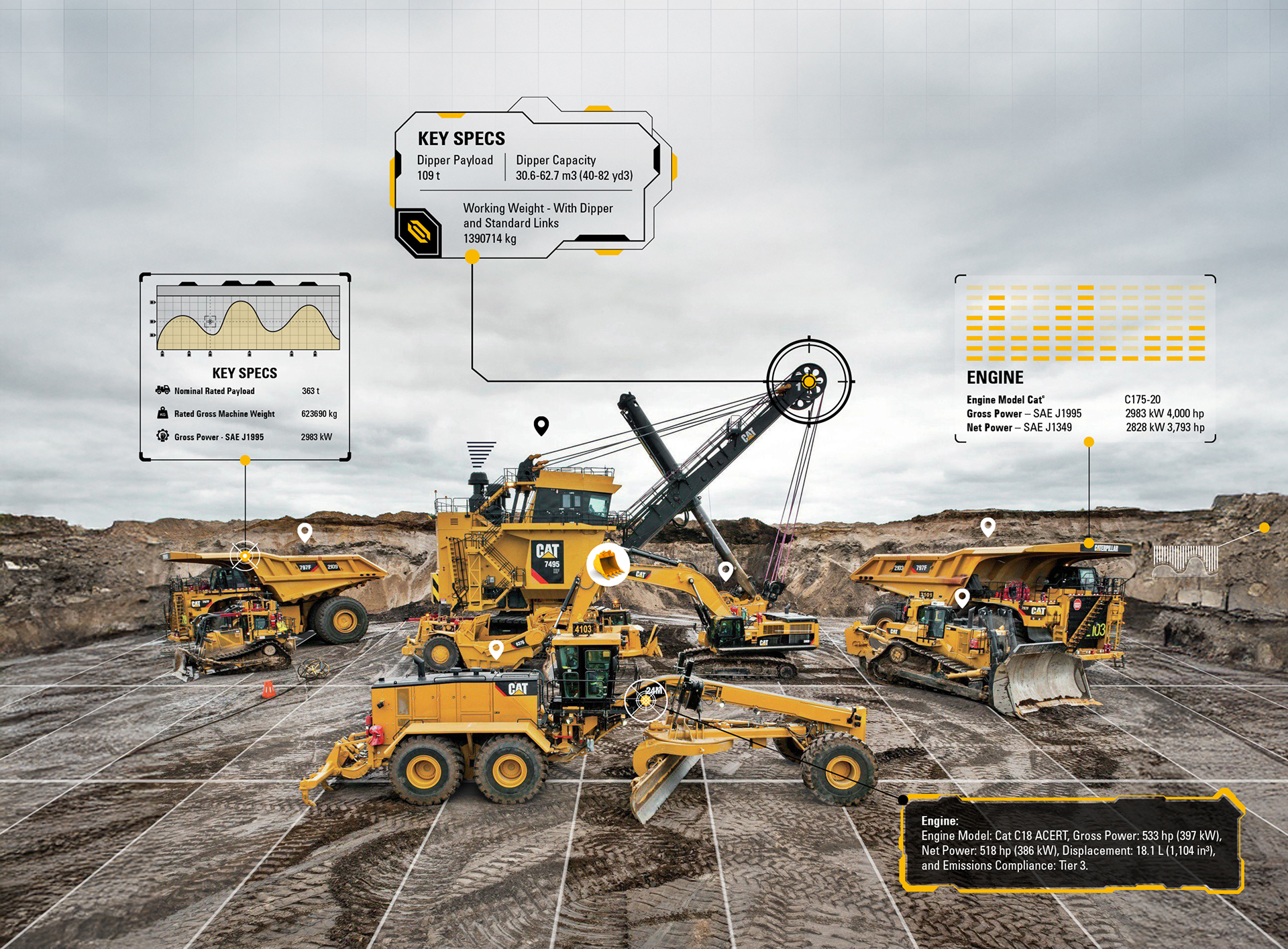

The earth-moving industry, mining and construction have long been defined by brawn, grit, and the sheer power of heavy machinery. Traditionally, managing vast fleets of equipment has been a reactive process, reliant on manual checks, scheduled maintenance, and often, the costly lessons of unexpected breakdowns. Today, however, a quiet revolution is underway, driven by the Internet of Things (IoT) and sophisticated telemetry devices. These technologies are fundamentally changing how assets are managed, maintained, and optimised, heralding an era of unprecedented efficiency, safety, and profitability.

At the heart of this transformation lies the "connected asset". Every modern piece of heavy equipment, from colossal excavators to agile skid steers, can now be outfitted with sensors and communication technologies that transmit a constant stream of vital data. This is a radical departure from the past, where machine performance was often gauged by operator experience and the periodic assessments of field technicians.

The Undeniable Advantages of a Connected Asset

The shift to connected assets offers a multitude of compelling advantages:

- Proactive Maintenance and Maximised Uptime: The most significant benefit is the ability to move from reactive repairs to predictive maintenance. Telemetry data provides real-time insights into machine health, engine parameters, hydraulic pressure, fluid levels, and more. Anomalies can be flagged immediately, allowing for interventions before minor issues escalate into major failures.

- Optimised Performance and Fuel Efficiency: A connected asset offers granular data on operational efficiency. Fuel consumption, idle times, payload weights, and cycle times can all be meticulously tracked and analysed. This allows operators and fleet managers to identify inefficiencies, optimise work patterns, and implement strategies that significantly reduce fuel expenditure, a major operating cost in both mining and construction.

- Enhanced Safety: By monitoring machine behaviour and operator performance, connected assets contribute significantly to a safer working environment. Telemetry can detect signs of operator fatigue, excessive speeds, or unsafe operating practices, enabling timely interventions and training. In the event of an incident, precise location data and machine diagnostics can expedite emergency response.

- Improved Asset Utilisation and Logistics: Knowing the exact location and operational status of every machine in real-time is a game-changer for logistics and fleet management. Assets can be deployed more strategically, reducing unnecessary travel and optimising workflow across diverse sites. This also aids in preventing theft and ensuring compliance with operational plans.

- Data-Driven Decision Making: Beyond immediate operational benefits, the wealth of data generated by connected assets empowers businesses to make truly informed decisions. Trends in machine performance, wear and tear patterns, and operational efficiency can be analysed over time, leading to better procurement strategies, more accurate budgeting, and optimised long-term asset management.

Barloworld Equipment: EMPOWERING Our Customers with Connected Intelligence

We understand that our customers' success is intrinsically linked to the performance and reliability of their machinery. This is why we have wholeheartedly embraced IoT and telemetry, integrating these cutting-edge technologies into our core service offerings to deliver tangible value.

All Caterpillar machines we supply come fitted with standard telemetry devices, a crucial enabler for our digitally enabled customer experience. This isn't just about providing equipment; it's about unlocking a new level of operational insight. Through a seamless onboarding process, we empower our customers with a suite of digital tools designed to put control firmly in their hands.

Our customers gain immediate access to platforms like VisionLink and Minestar, which transform raw machine data into actionable insights. They can monitor fuel consumption to drive down costs, track machine locations for improved logistics, and analyse machine health proactively to prevent downtime. Complementing this, CAT Inspect provides easy access to fault codes and inspection histories, all designed to maximise uptime and minimise disruptions.

Furthermore, our dedicated team of condition monitoring analysts leverages this vast stream of data to offer expert analysis and proactive recommendations. This blend of cutting-edge technology and human expertise ensures that our customers are not just operating machines but intelligently managing a connected fleet, making better-informed decisions that are backed by our comprehensive service suite.

In an industry constantly striving for greater efficiency and safety, the connected asset is no longer a luxury but a necessity. At Barloworld Equipment, we are proud to be at the forefront of this digital transformation, empowering our customers to master the machine lifecycle and build a more productive future.

To learn more about our Digitally Enabled Customer Journey, watch the video below:

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS

%20Image%20January%2022%2c%202026%20-%204_13PM%20V1%20(1).jpeg?width=352&height=352&name=The%20Mining%20Powerhouse%20(SEM%20Wheel%20Loader)%20Image%20January%2022%2c%202026%20-%204_13PM%20V1%20(1).jpeg)