US

METRIC

836

KEY SPECS

- Gross Power - SAE J1995:2014 419kW

- Net Power - SAE J1349:2011 370kW

- Net Power - ISO 9249:2007 374kW

OVERVIEW

BENEFITS

-

IMPROVED PERFORMANCE

- Improved operation with smoother directional shifts due to Cat locker differentials

-

ENHANCED TECHNOLOGY

- Boost your productivity with standard technologies like Cat Compact with Pass Mapping and optional Cat Compact with Elevation Mapping

-

IMPROVED GUARDING

- New features such as additional axle Duo-cone® seal guards, eyebrow guards, and new reversing fan guard help protect the machine from trash intake andother onsite hazards

FEATURES AT A GLANCE

OPERATOR COMFORT AND CONTROL

- Flip-up armrest for easy ingress/egress.

- Keep your operators informed about machine conditions and operation with Vital Information Management System (VIMS™) 3G machine monitoring system.

- Enhanced visibility with standard rearview camera.

- Preferred temperature settings maintained with automatic climate control.

- Cat Premium Plus seat with standard features including leather finish, forced air heating and cooling, two-way thigh adjustment, power lumbar and back bolster adjustment, and dynamic end dampening to help provide total comfort throughout the workday.

- Increased forward visibility with lowered glass for better visibility to the blade and wheels.

BECAUSE UPTIME COUNTS

- Easy access and in a controlled environment; electronics bay is located inside the cab.

- Focused on safety with ground level or platform access to most major components.

- Ground level: emergency shutdown, battery disconnect, and jump start.

- Quick visual inspection and minimize fluid contamination with sight gauges for coolant, transmission, and hydraulic oil.

- Electronic air inlet restriction indicator.

- Designed for ease of service and inspection– Hydraulic oil cooler, fuel cooler, and roof-mounted condenser– Centralized grease points.

- Operators and technicians can resolve any problems before failure using VIMS.

- Underhood lighting for improved visibility of service points.

- Improved guarding around the axles mitigates risk of damaged components.

- Improved radiator air inlet door sealing to help reduce radiator cleanout.

- Remaining useful life of the engine air filter helps allow for better planning of maintenance and repair activities.

POWERFUL EFFICIENCY

- Improved performance, long life, low emissions.

- High productivity and fuel efficient.

- Two engine options available that meet U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 emission standards or Brazil MAR-1 equivalent to U.S. EPA Tier 3/EU Stage IIIA.

- For the Tier 4 Final, EU Stage V, Korea Stage V, and Japan 2014 option, the Cat Clean Emissions Module contains a diesel oxidation catalyst, diesel particulate filter, and Cat Regeneration System, utilizing selective catalytic reduction (SCR) technology.

- Regeneration is completely automatic and does not interrupt the machine’s work cycle.

- Experience maximum responsiveness and control with Steering and Transmission Integrated Control System (STIC™).

- Conserve more fuel with the automatic engine and electrical system shutdown.

- Achieve greater momentum on grades and fuel savings by carrying that momentum through the shift points advanced productivity electronic control system (APECS) transmission controls.

- Operators experience less fatigue with throttle lock to maintain engine speed.

- Equipped with Cat torque converter with lock-up clutch which eliminates torque converter (TC) losses while lowering system heat and transfers more power to the ground.

- Improved direction shift speed with new Cat locker differentials.

- Diesel exhaust fluid (DEF) injector phase change tank to reduce engine idle time at shutdown.

- Increase machine tarp lift capability to eliminate need for track type tractor to carry tarp rolling equipment for end of day landfill cover.

PRODUCTIVITY WITH TECHNOLOGY

- Compact technology combines advanced compaction measurement, in-cab guidance, and reporting capabilities to help you consistently meet compaction targets fast, uniformly, and in fewer passes – saving on fuel and the cost of unnecessary rework.

- Link technology (standard) provides access to machine location, hours, fuel consumption, idle time, events, and diagnostic codes through the online VisionLink® interface.

- Improved productivity with standard Cat Compact with Pass Mapping and 10" display.

- Slope indicate feature helps improve construction of slopes and identifies when risk for fluid cavitation occurs.

- Improved productivity with optional Cat Compact with Elevation Mapping.

LONG TERM VALUE AND DURABILITY

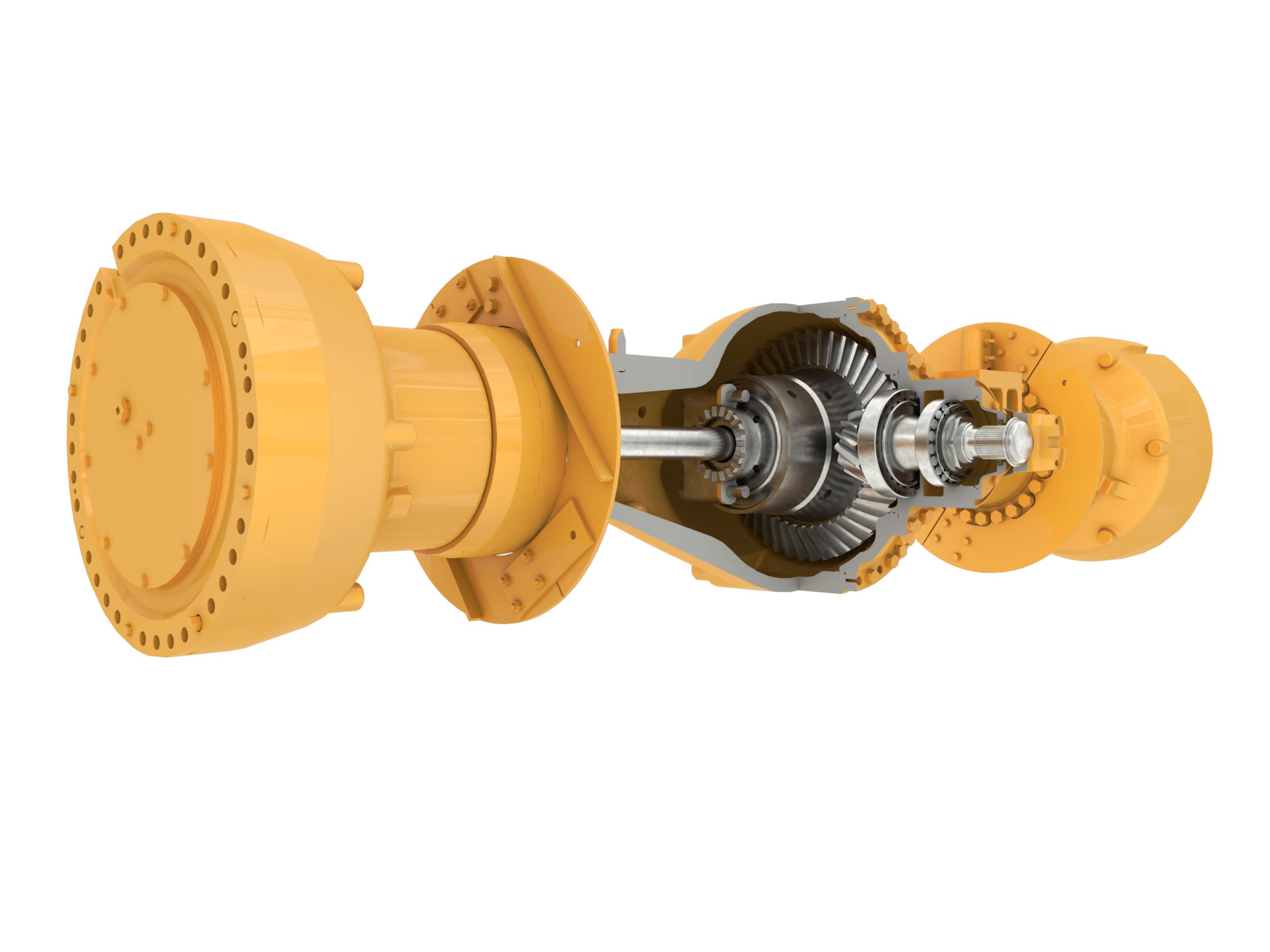

- Larger diameter axle shafts, the Cat locker differentials, improved duo cone labyrinth, thicker wheel at the spindle for increased strength.

- Improved final drive gear set to help reduce stress and enhance pitting life.

- Fan motor guard to help prevent bag wrapping.

- 5" higher efficiency fuel filter for cleaner fuel to the engine.

WHEEL TIPS BUILT TO PERFORM

- Designed specifically to complement Cat machines.

- Improves machine performance through longer wear life and maintaining traction.

- Five wheel and tip configurations are available to meet your particular application:

1) Paddle Tip – High performance and less fuel burn with more traction and less weight.

2) Plus Tip – Traditional design for increased side slope stability.

3) Combination Tip – Both paddle and plus tips help provide the best compromise of performance and fuel economy with side slope stability.

4) Diamond Tip – Longest life tip on the market with reputation of reliability that is world class in the waste tip industry.

SPECIFICATIONS

- Gross Power - SAE J1995:2014 419kW

- Net Power - SAE J1349:2011 370kW

- Net Power - ISO 9249:2007 374kW

- Engine Model Cat® C18

- Emissions Option 1 - U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V and Japan 2014

- Rated Speed 1900 rpm

- Engine Power - ISO 14396:2002 412kW

- Emissions Option 2 - Brazil MAR-1, equivalent to U.S. EPA Tier 3/EU Stage IIIA

- Rated Speed 1900 rpm

- Net Power - SAE J1349:2011 370kW

- Net Power - ISO 9249:2007 374kW

- Gross Power - SAE J1995:2014 419kW

- Engine Power - ISO 14396:2002 412kW

- Peak Torque ( 1,400 rpm ) 3085N·m

- Torque Rise 52%

- Bore 145mm

- Stroke 183mm

- Displacement 18.1l

- High Idle Speed 2120r/min

- Low Idle Speed 750r/min

- Maximum Altitude - Without Derating 2286m

- Note Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator.

- Operating Weight (Tier 4 Final/Stage V) 56275kg

- Operating Weight (Tier 3/Stage IIIA equivalent) 55939kg

- Maximum Operating Weight (Tier 4 Final/Stage V) 57318kg

- Maximum Operating Weight (Tier 3/Stage IIIA equivalent) 56982kg

- Transmission Type Planetary - Powershift - ECPC

- Direct Drive - Forward 1 7.0km/h

- Direct Drive - Forward 2 12.6km/h

- Direct Drive - Reverse 1 7.4km/h

- Direct Drive - Reverse 2 13.2km/h

- Lift System - Circuit Flow Sharing Implement; Pilot Operated LS Valve w/EH

- Lift System - Pump Variable displacement piston

- Max Flow @ 2000 rpm 300L/min

- Relief Valve Setting - Lift 29000kPa

- Cylinders, Double Acting: Lift, Bore, Stroke 137.9 mm x 1021 mm (5.5 in x 40.2 in)

- Pilot System Variable displacement piston

- Pilot Relief Valve Setting 3800kPa

- Steering System - Circuit Flow Sharing Implement; Pilot, load sensing

- Steering System - Pump Piston – Variable Displacement

- Max Flow @ 2000 rpm 300L/min

- Relief Valve Setting - Steering 24100kPa

- Total Steering Angle 86°

- Steering Cycle Times - High Idle 3.9s

- Steering Cycle Times - Low Idle 6.4s

- Fuel Tank 793.0l

- Diesel Exhaust Fluid Tank 32.8l

- Cooling Systems - Tier 4 Final/EU Stage V 151.5l

- Cooling System - Tier 3/Stage IIIA Equivalent 141.1l

- Engine Crankcase 60l

- Transmission 83l

- Differential - Final Drives - Front 186.0l

- Differential - Final Drives - Rear 190.0l

- Hydraulic System - Implement/Steering 175l

- Hydraulic Tank Only 103l

- Note Cat U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V and Japan 2014 diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) and are compatible* with ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester)*** • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels • Cat engines meeting Brazil MAR-1 emissions standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA, are compatible with diesel fuel blended with the following lower-carbon intensity fuels** up to: • 100% biodiesel FAME (fatty acid methyl ester)*** • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * While Caterpillar engines are compatible with these alternative fuels, some regions may not allow their use. ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. *** Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).

- Air Conditioning The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system contains 1.4 kg (3.1 lb) of refrigerant which has a CO2 equivalent of 2.002 metric tonnes (2.206 tons).

- Front Planetary – Fixed

- Rear Planetary – Oscillating

- Oscillation Angle ±6°

- Service Brakes Multi Disc Wet (Enclosed) 2 WHL

- Parking Brake Spring Applied, Hydraulic Released

- Operator Sound Pressure Level (ISO 6396:2008) 72dB(A)

- Machine Sound Power Level (ISO 6395:2008) 112dB(A)

- Operator Sound Pressure Level (ISO 6396:2008)* 72dB(A)

- Machine Sound Power Level (ISO 6395:2008)* 109dB(A)

- Note (1) * Sound suppression equipped

- Note (2) The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

- Note (3) The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

- Note (4) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Operator Sound Pressure Level (ISO 6396:2008) 72dB(A)

- Machine Sound Power Level (ISO 6395:2008) 112dB(A)

- Operator Sound Pressure Level (ISO 6396:2008)* 72dB(A)

- Machine Sound Power Level (ISO 6395:2008)* 110dB(A)

- Note (1) * Sound suppression equipped

- Note (2) The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

- Note (3) The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

- Note (4) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Height to Top of Beacon 4634mm

- Height to Top of Air Conditioning Condenser 4626mm

- Height - Cab Roof 4285mm

- Height - Top of Exhaust Pipe 4606mm

- Height - Top of Hood 3430mm

- Ground Clearance to Hitch 639mm

- Ground Clearance to Transmission Guard 634mm

- Ground Clearance to Bottom of Bumper 965mm

- Centerline of Rear Axle to Rear Compactor Guard 3454mm

- Hitch to Centerline of Front Axle 2275.0mm

- Wheel Base 4550.0mm

- Width over Front Striker Bars 3930mm

- Width over Rear Striker Bars 3933mm

- Width over Platform 3196mm

- Width over Drums 4280mm

- Overall Machine Length with Semi U-Blade 10914mm

- Capacity 19.8m³

- Overall Width 5193mm

- Height 2260mm

- Height of Cutting Edge 1125mm

- Digging Depth 364mm

- Ground Clearance 1730mm

- Turning Radius – Outside Corner of Blade 8737mm

- Turning Radius - Inside of Wheels 3635mm

- Weight 3127kg

- Total Operating Weight 55931kg

- Capacity 22.4m³

- Overall Width 5313mm

- Height 2294mm

- Height of Cutting Edge 1255mm

- Digging Depth 362mm

- Ground Clearance 1735mm

- Turning Radius – Outside Corner of Blade 8823mm

- Turning Radius – Inside of Wheels 3635mm

- Weight 3612kg

- Total Operating Weight 56413kg

- Capacity 25.7m³

- Overall Width 5290mm

- Height 2204mm

- Height of Cutting Edge 1255mm

- Digging Depth 934mm

- Ground Clearance 1198mm

- Turning Radius – Outside Corner of Blade 8795mm

- Turning Radius – Inside of Wheels 3635mm

- Weight 3491kg

- Total Operating Weight 56287kg

- Combination Tips (Weight Group) 12814kg

- Plus Tips - Weight (Group) 13510kg

- Paddle Tips - Weight (Group) 12350kg

- Diamond Tips Weight (Group) 14814kg

- Outside Diameter 2128mm

- Outside Diameter - Diamond 2140mm

- Drum Diameter 1770mm

- Drum Width 1400mm

- Feet Per Row 8

- Feet Per Wheel 40

- Replaceable Weld on

- Width Over Drums 168.5in

- Tip Height 7.0in

- Tip Height - Diamond 184mm

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS