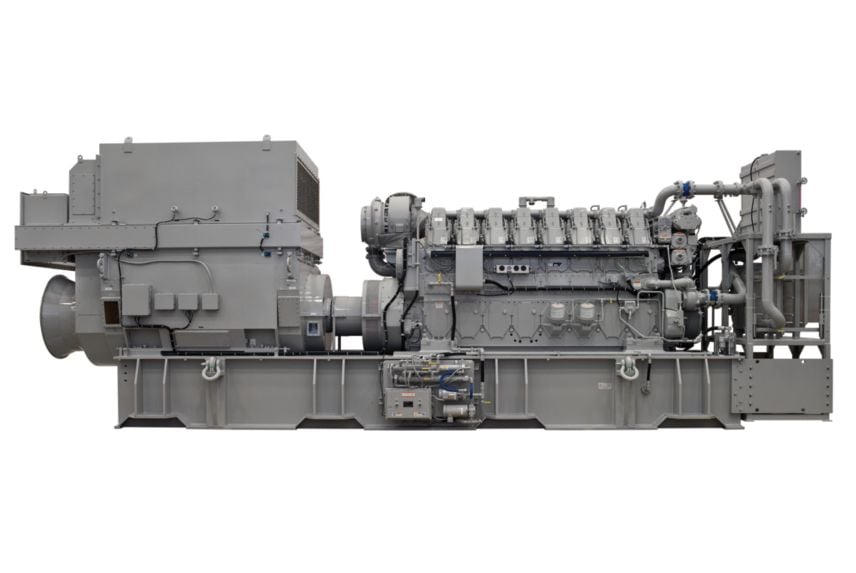

SPECIFICATIONS

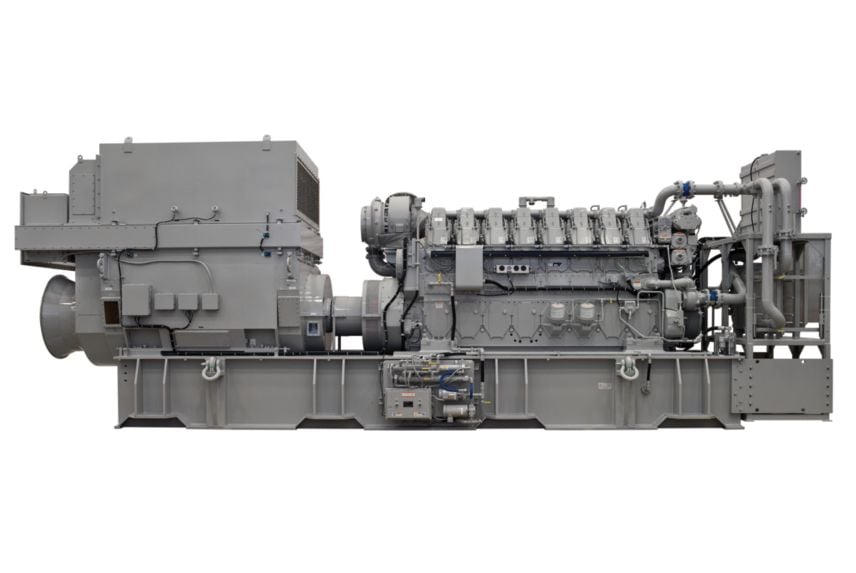

- Minimum Rating 2300 ekW3084 kV·A

- Maximum Rating 2710 ekW3634 kV·A

- Aspiration Turbocharged-Aftercooled

- Fuel System EUI

- Bore 280 mm11 in

- Displacement 148 l9031 in³

- Stroke 300 mm11.8 in

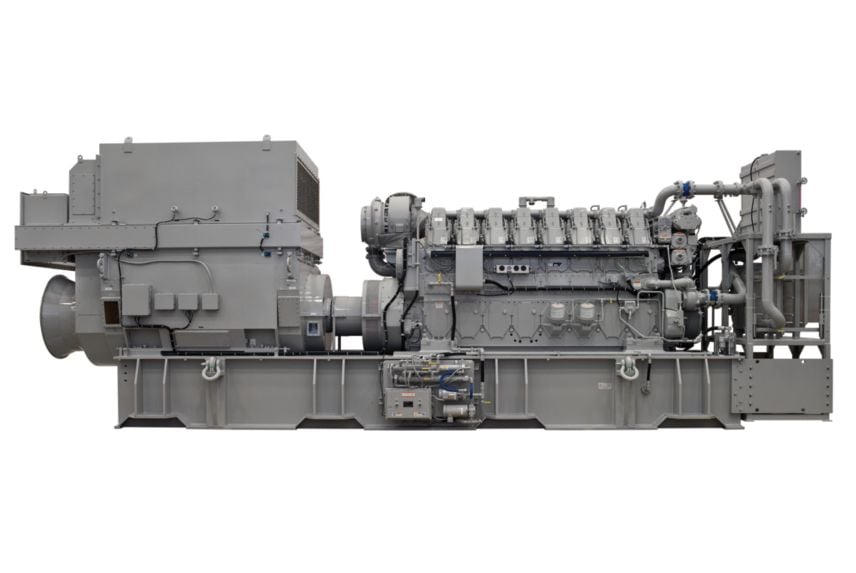

- Length 8140 mm320.5 in

- Width 2326 mm91.6 in

- Height 3406 mm134.1 in

- Emissions IMO Tier II/EPA Marine Tier 2

- Oil Change Interval 1000 h1000 h

- Lube Oil System Refill 1094 l289 gal (US)

- Cooling System Engine 530 l140 gal (US)

- Weight 49000 kg108027 lb

- Generator Set Control Generator Monitoring System (GMS)

- Engine Control Electronic ADEM™ A3

- Industry oil-and-gas

EQUIPMENT

C280-8 Standard Equipment

- Product Consist

- The engine is a turbocharged, aftercooled, four-strokecycle-diesel, electronic unit injection engine with a280 mm (11 in) bore by 300 mm (11.8 in) stroke. SAEstandard rotation is counterclockwise as viewed from therear of engine flywheel.

- Emissions Certifications

- GL and CCS approved IMO certificate — includesstatement of compliance or Engine International AirPollution Prevention (EIAPP) certificate, supplied by theRecognized Organization (RO) where available, andtechnical file to be kept on board per IMO regulations.

- Marine Certification Society type-approval

- ABS, BV, CCS, DnV, GL, LRS

- Spray shielding to meet SOLAS regulations for flammablefluids

- European Certifications

- Declaration of Incorporation for EU Machinery Safety

- Directive and EU Low Voltage Safety Directive

- Air Inlet System

- Fresh water aftercooler, corrosion resistant coated (airside)

- Air inlet shutoff

- Turbocharger, rear-mounted, oil lubricated

- Control System

- Single Cat ADEM A3 electronic engine control module withelectronic unit injector fuel system, rigid wiring harness(10 amp 24V power required to drive electronic enginecontrol modules)

- Cooling System

- Gear-driven jacket water (JW) pump

- Gear-driven separate-circuit aftercooler/oil cooler (AC/OC) pump

- Engine coolant water drains

- Exhaust System

- Dry, gas tight exhaust manifold

- Fuel System

- Distillate fuel (requires viscosity ranging from 1.4 cStto 20 cSt at 38°C)

- Fuel pump, gear-driven

- Fuel transfer pump (mounted on left-hand side)

- Duplex fuel filters, rear-engine-mounted

- Electronically controlled unitinjectors

- Lube system

- Centrifugal oil filters with single shutoff, service-side enginemounted on cylinder block inspection covers (includesinstalled oil lines and single shutoff valve), filters centrifugebypass oil from the main lubricating oil pump (can be servicedwith the engine running)

- Oil filler and dipstick

- Oil pressure regulating valve

- Dry engine-mounted sump system that gravity feeds intobase assembly integral sump

- Engine-mounted duplex oil filter

- Intermittent air prelube

- Continuous electric prelube

- Redundant prelube with continuous electric prelube andintermittent air prelube backup

- Oil pan drain valves

- Electric continuous prelube pump

- Lube oil heater

- Oil pump - gear drive

- Protection System

- Crankcase explosion relief valves

- Alarm and shutdown during abnormal operation

- Instrumentation

- PLC-based system provides protection, monitoring, andcontrol housed in a NEMA 4 (IP66) enclosure.

- General

- Service Literature

C280-8 Optional Equipment

- Air Inlet System

- 90° adapter and straight adapters for air inlet to turbochargerAir cleaners

- Air cleaners with Cat dry paper filter elements (approximately99.9% efficient at filtering SAE fine dust)

- Soot filter

- Control System

- 4-20 mA load feedback signal

- Load sharing module

- Direct rack module

- Cooling System

- Separate Circuit Aftercooler (SCAC)

- Customer water connections

- Jacket water thermostats

- AC/OC thermostats

- Accessory module-mounted high volume expansion tank

- Jacket water heater

- Heat recovery connections and thermostats for use withwater maker system

- ANSI connection adapters

- Exhaust System

- Exhaust manifold shields

- Vertical or 30° outboard exhaust orientation options

- Exhaust outlet expanders and weld flanges

- Fuel System

- Manual fuel priming pump

- Duplex primary fuel strainer

- Flexible fuel hose connections

- Lube System

- Dry engine-mounted sump system that gravity feeds intobase assembly integral sump

- Engine-mounted duplex oil filter

- Intermittent air prelube

- Continuous electric prelube

- Redundant prelube with continuous electric prelube andintermittent air prelube backup

- Oil pan drain valves

- Electric continuous prelube pump

- Lube oil heater

- Protection System

- Wiring meets MCS requirements

- Upgrade PLC monitor to industrial PC

- Upgrades AC/OC, JW and start air pressure from contactorsto transducers

- Raw water/sea water pressure transducer

- Modbus communication

- Beacon and horn

- Single engine remote display monitor

- Emergency pump start signal

- Cabinet cooler

- Generator power monitoring

- Remote relay panel

- Turbocharger speed sensors

- Cylinder pressure relief valve

- Oil mist detector

- Flywheel and damper guards

- Mounting System

- Base aseembly

- Vertically-restrained vibration isolators and weld plates

- Starting System

- Single turbine air starters

- Boost control valve for extremely cold ambient conditions

- Air start pressure reducing valves

- General

- Torsional couplings

- Mounting groups for engine, generator, and base

- Accessory module to mount attachments such as theexpansion tank, heat exchanger, instrument panel andengine controls, annunciator panel, alarm and shutdowncontactors, fuel strainer

- Flywheel

- Engine barring device options:

- One-year storage preservation

- Oceanic transportation shipping protection (shrink wrapand tarp)

- Engine testing — certified dynamometer test, fuelconsumption test, rated speed performance test, overloadtest, minimum power setting, peak firing pressure test,turbo work cert and crankshaft work cert

- Standard and project-specific witness testing

- Spare parts kits

- Literature

- Project-specific installation drawings

- Electrical schematics and P&ID drawings

RELATED PRODUCTS

CN1566 Electric Motor

oil and gas

- Electric Motor Type: Squirrel Cage Induction Motor

- Full Load Speed: 1189 r/min1189 r/min

- Mounting Designation: F1 or F2

CN3086 Electric Motor for Gas Compression

oil and gas

- Electric Motor Type: Squirrel Cage Induction Motor

- Full Load Speed: 892 r/min892 r/min

- Mounting Designation: F1 or F2

CN3586 Electric Motor for Gas Compression

oil and gas

- Electric Motor Type: Squirrel Cage Induction Motor

- Full Load Speed: 894 rpm

- Mounting Designation: F1 or F2

CN5086 Electric Motor

oil and gas

- Electric Motor Type: Squirrel Cage Induction Motor

- Full Load Speed: 894 r/min894 r/min

- Mounting Designation: F1 or F2

3406C

oil and gas

- Minimum Rating: 217 bkW292 BHP

- Maximum Rating: 359 bkW482 BHP

- Aspiration: Turbocharged Aftercooled

3412

oil and gas

- Minimum Rating: 476 bkW638 BHP

- Maximum Rating: 551 bkW739 BHP

- Aspiration: Turbocharged Aftercooled

3508

oil and gas

- Minimum Rating: 709 bkW950 BHP

- Maximum Rating: 795 bkW1065 BHP

- Aspiration: Turbocharged Aftercooled

3512

oil and gas

- Minimum Rating: 1066 bkW1430 BHP

- Maximum Rating: 1195 bkW1600 BHP

- Aspiration: Turbocharged Aftercooled

3516

oil and gas

- Minimum Rating: 1417 bkW1900 BHP

- Maximum Rating: 1480 bkW1985 BHP

- Aspiration: Turbocharged Aftercooled

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS