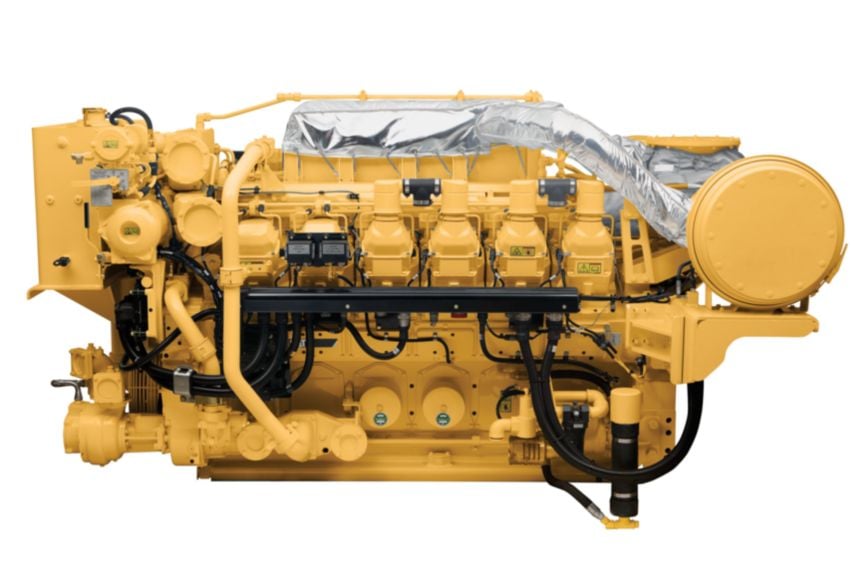

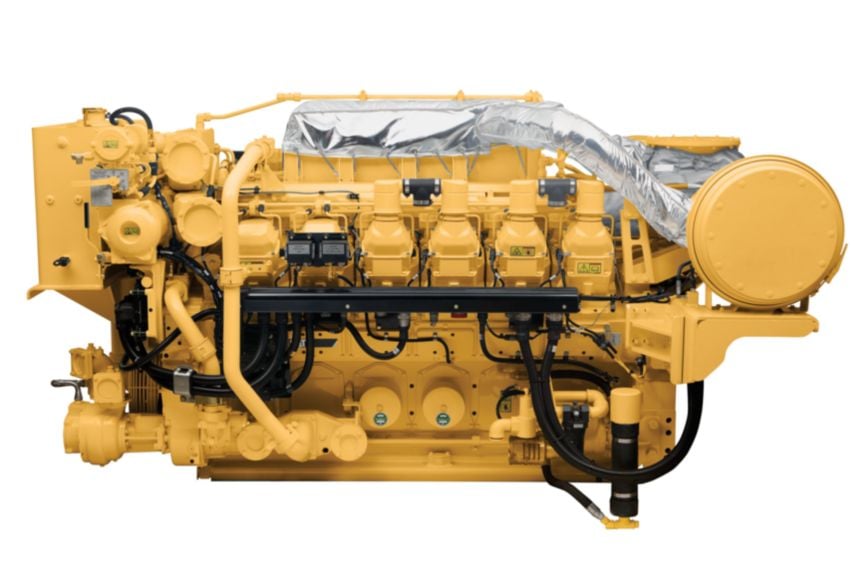

SPECIFICATIONS

- Minimum Rating 1550 eKW (1937 kVA)

- Maximum Rating 1700 eKW (2125 kVA)

- Frequency 60 hz

- Speed 1800

- Aspiration TTA

- Bore 170 mm6.7 in

- Displacement 58.56 l3574 in³

- Stroke 215 mm8.46 in

- Configuration Vee 12 4-Stroke-Cycle Diesel

- Length 5085.3 mm200.2 in

- Width 2142.1 mm84.3 in

- Height 2131.1 mm83.9 in

- Emissions IMO II

- Weight Estimated 12762 kg28136 lb

- Industry marine-power-systems

EQUIPMENT

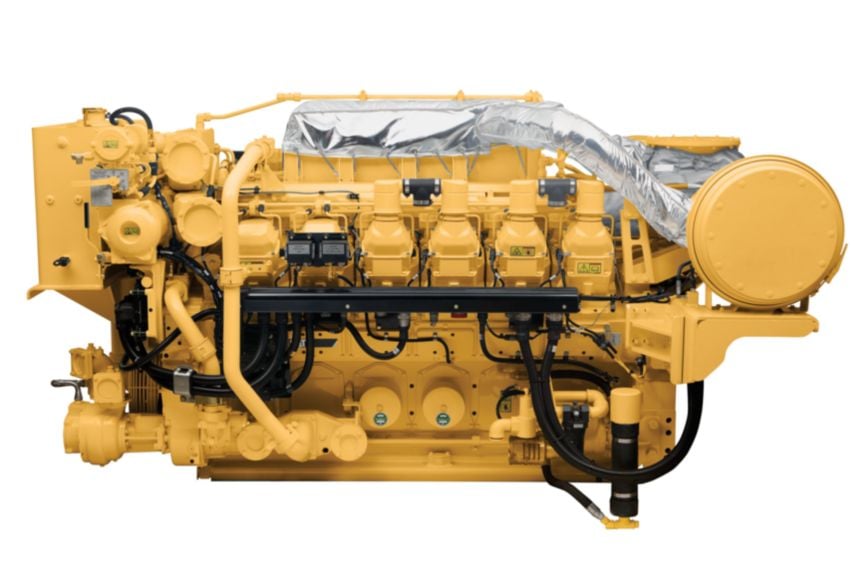

3512C Standard Equipment

- AIR INLET SYSTEM

- Corrosion resistant separate circuit aftercooler core, regular duty air cleaners, dual turbochargers

- CONTROL SYSTEM

- Caterpillar A-III electronic engine control, Electronic Unit Injection fuel system, rigid wiring harness

- COOLING SYSTEM

- Auxiliary fresh water pump, centrifugal non-self-priming auxiliary sea water pump, gear driven centrifugal jacket water pump, expansion tank, engine oil cooler, thermostats and housing

- EXHAUST SYSTEM

- Dry gas-tight exhaust manifolds with heat shields, dual turbochargers with water-cooled bearings and heat shields, vertical exhaust outlet

- FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel, SAE No. 00, 183 teeth Flywheel housing, SAE No. 00

- FUEL SYSTEM

- Fuel filter, RH, with service indicators

- Fuel transfer pump

- Electronically Controlled Unit Injectors

- INSTRUMENTATION

- Engine mounted instrument panel with four position switch, over speed shutdown notification light, emergency stop notification light, graphical display unit for analog or digital display of: oil and fuel pressure, oil and fuel filter differential, system DC voltage, exhaust and water temperature, air inlet restriction, service meter, engine speed, fuel consumption (total and instantaneous)

- LUBE SYSTEM

- Top mounted crankcase breather, RH oil filter, RH oil filler, gear type oil pump, deep sump oil pan, recommended use of Caterpillar Diesel Engine Oil 10W30 or 15W40

- MOUNTING SYSTEM

- Industrial type engine mounting rails)

- POWER TAKE-OFFS

- Accessory drive Lower RH, Lower LH Front housing, Two-sided

- PROTECTION SYSTEM

- A-III Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection for oil pressure and water temperature, over speed protection

- GENERAL

- Vibration damper and guard Paint, Caterpillar Yellow engine with black rails. Lifting eyes

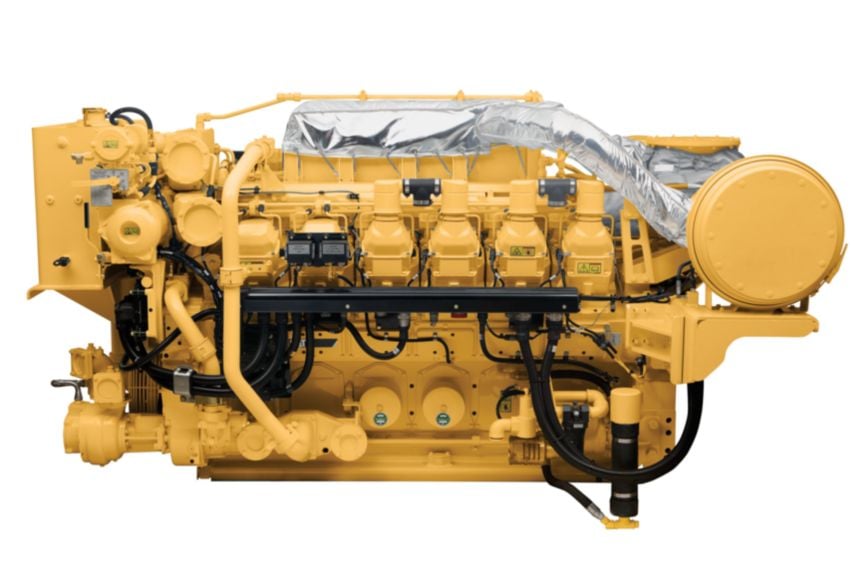

3512C Optional Equipment

- AIR INLET SYSTEM

- Air Cleaner Removal

- Remote Air Inlet Adapters

- CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- CONTROL SYSTEM

- Load Sharing module

- Local speed throttle control

- COOLING SYSTEM

- Water level switch gauge

- Coolant level sensors

- Connections

- Keel Cooling Conversions

- Radiator cooling conversion

- Heat exchangers

- Auxiliary water pumps

- Sea water pump removal

- Air separator

- EXHAUST SYSTEM

- Exhaust outlet

- Flexible fittings

- Elbows

- Flanges

- Flange and exhaust expanders

- Mufflers

- FUEL SYSTEM

- Fuel Cooler

- Fuel priming pumps

- Flexible fuel lines

- Rigid Fuel Lines

- Primary fuel filter

- Fuel level switch

- GENERATORS AND GENERATOR ATTACHMENTS

- 1500/1800 RPM, 1000/1200 RPM

- Low Voltage Connection

- Generator Conversion

- Low Voltage Extension Box

- RFI Filter

- Bearing Temperature Detectors

- Manual Voltage Control

- Air Filter

- INSTRUMENTATION

- PL1000T Communication Module

- PL1000E Communication Module

- Customer Interface Box

- Thermocouples

- Remote panel display

- Remote cylinder temperature display

- LUBE SYSTEM

- Oil Pan

- Oil pan accessories

- Sump pumps

- Prelubrication Options

- Lubricating oil

- Centrifugal Oil Filter

- MOUNTING SYSTEM

- Vibration isolators

- Rails

- POWER TAKE-OFFS

- Flywheel guard

- Flexible coupling

- Coupling hub

- Front housing accessories

- Upper left hand front location

- Upper left hand rear location

- Upper right hand front location:

- Upper right hand rear location

- Lower left hand front location

- Front housing accessory drives

- Front power take-offs

- Crankshaft pulleys

- Damper guard removals

- PROTECTION SYSTEM

- Air inlet shutoffs

- Switches and contactors

- Explosion relief valve

- Sensors

- STARTING SYSTEM

- Starting motors or barring divice

- Air starting motors options

- Battery sets - 24 volt - Dry

- Battery rack

- Jacket Water Heater

- GENERAL

- Tool set

- Caterpillar datalink wire

- SVCE TOOLS/SHIP PROT/FACTORY SUPPORT

- Commissioning

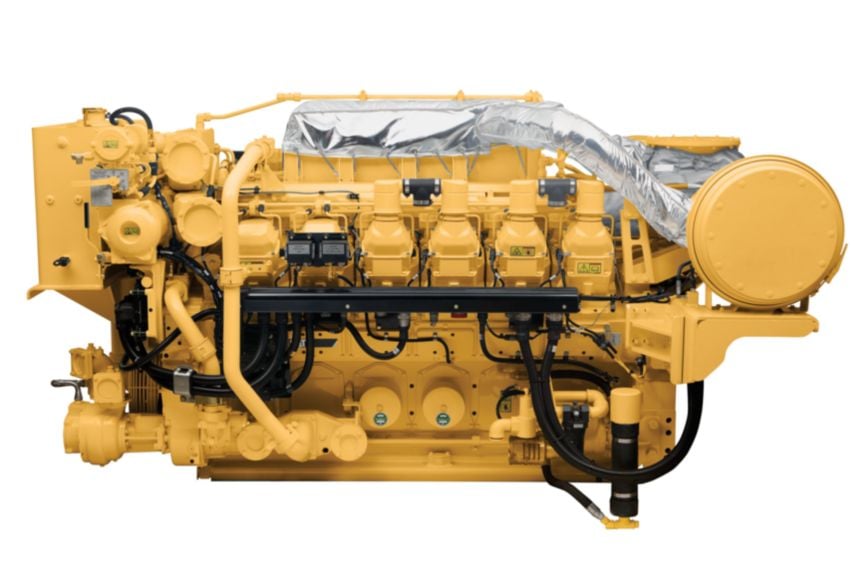

RELATED PRODUCTS

3512E

marine power systems

- Aspiration: TA

- Bore: 170 mm6.69 in

- Displacement: 58.6 l3574 in³

C18 IMO II

marine power systems

- Minimum Rating: 301 bkW404 BHP

- Maximum Rating: 492 bkW660 BHP

- Aspiration: TA, TTA

C18 Tier 3

marine power systems

- Minimum Rating: 465 bkW624 BHP

- Maximum Rating: 599 bkW803 BHP

- Aspiration: TA, TTA

C280

marine power systems

- Minimum Rating: 1730 bkW2320 BHP

- Maximum Rating: 5420 bkW7268 BHP

- Aspiration: TA

C32 IMO II

marine power systems

- Minimum Rating: 590 bkW791 BHP

- Maximum Rating: 994 bkW1333 BHP

- Aspiration: TTA

C32 IMO III

marine power systems

- Minimum Rating: 262 bkW352 BHP

- Maximum Rating: 874 bkW1172 BHP

- Aspiration: Turbocharged-aftercooled aspiration

C32 Tier 3

marine power systems

- Minimum Rating: 781 bkW1047 BHP

- Maximum Rating: 994 bkW1333 BHP

- Aspiration: TTA

C32 Tier 3 / IMO II

marine power systems

- Minimum Rating: 234 bkW314 BHP

- Maximum Rating: 994 bkW1333 BHP

- Aspiration: Turbocharged-aftercooled aspiration

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS