US

METRIC

814K

KEY SPECS

- Engine Model C7.1 Cat®

- Transmission Type Cat Planetary Power Shift

- Oscillation Angle ±11°

OVERVIEW

BENEFITS

-

IMPROVED EFFICIENCY

- Designed to be more efficient with advanced engineering, providing precise operational control

-

ADDITIONAL SAFETY

- Equipped with standard safety features, improving visibility and providing a safer operating environment

-

ENHANCED DURABILITY

- Durable structures built to withstand the toughest conditions while achieving multiple life cycles

FEATURES AT A GLANCE

Move More with Less Fuel

- New implement and steering variable displacement load sensing piston pumps.

- Hydraulic flow now on demand, for improved fuel efficiency.

The Cat C7.1 engine is designed for maximum fuel efficiency and increased power density.

The Cat C7.1 engine is designed for maximum fuel efficiency and increased power density.- Features innovative Cat electronics, fuel injection process, air-management systems and aftertreatment solution (for Tier 4 Final) with Cat Selective Catalytic Reduction.

- Innovative systems effectively lower the average working engine speed and reduce overall system heat loads for improved performance and fuel efficiency.

- Deep system integration amongst engine and emissions system, power train, hydraulic and cooling system result in lower fuel consumption on average compared to the previous model.

Long Term Value and Durability

Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest conditions.

![]()

- Full box-section rear frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts efficiently transmit steering loads into the frame.

- Axle mounting has been optimized for increased structural integrity.

- Upper hitch pin, frame plate, and bearing size have been increased for longer life.

- Push beams are through-width, not merely attached to side of frame.

- In corner dozing, stresses are transferred and absorbed through a larger portion of the frame.

Built to Perform

Experience maximum responsiveness and control with STIC that combines directional selection, gear selection and steering into a single lever. Building your success begins with a best-in-class transmission designed specifically for mining applications.

Building your success begins with a best-in-class transmission designed specifically for mining applications.![]() The Cat C7.1 engine is designed for maximum fuel efficiency and increased power density. Two engine options are available to meet the emission standards for Tier 4/Stage IV or Brazil MAR-1 and China Nonroad Stage III, equivalent to Tier 3/Stage IIIA.

The Cat C7.1 engine is designed for maximum fuel efficiency and increased power density. Two engine options are available to meet the emission standards for Tier 4/Stage IV or Brazil MAR-1 and China Nonroad Stage III, equivalent to Tier 3/Stage IIIA.

![]() The Tier 4 Final configuration:

The Tier 4 Final configuration:![]()

- Simple side-to-side motion turns machine right or left, minimizing operator movements.

- Easy to operate finger controlled gear selection.

- Smoother, faster cycles and less operator fatigue through the use of low effort integrated controls.

Building your success begins with a best-in-class transmission designed specifically for mining applications.

Building your success begins with a best-in-class transmission designed specifically for mining applications.- Consistent, smooth shifting and efficiency through integrated electronic controls that utilize Advanced Productivity Electronic Control Strategy (APECS).

- Long life and reliability through heat treat gear and metallurgy.

- Four forward and four reverse speeds to match your application.

- Engine is equipped with a Selective Catalytic Reduction (SCR) system which injects DEF into the exhaust to reduce NOx emissions.

- Cat NOx Reduction System (NRS) captures and cools a small quantity of exhaust gas, then routes in back into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

- While in operation, the aftertreatment will be seamless to the operator thanks to the passive regeneration system which is utilized.

Work in Comfort

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Your operator’s productivity is enhanced with our clean, comfortable cab environment.

Your operator’s productivity is enhanced with our clean, comfortable cab environment.![]() Enhance comfort and help reduce operator fatigue with Cat Comfort Series III seat.

Enhance comfort and help reduce operator fatigue with Cat Comfort Series III seat.![]() Ergonomic placement of switches and information display keep your operators comfortable all day every day.

Ergonomic placement of switches and information display keep your operators comfortable all day every day.![]() Enter and exit the cab easily and safely with a new fold up STIC armrest.

Enter and exit the cab easily and safely with a new fold up STIC armrest.

![]() Experience maximum responsiveness and control with STIC that combines directional selection, gear selection and steering into a single lever.

Experience maximum responsiveness and control with STIC that combines directional selection, gear selection and steering into a single lever.![]()

Your operator’s productivity is enhanced with our clean, comfortable cab environment.

Your operator’s productivity is enhanced with our clean, comfortable cab environment.- Experience reduced vibrations from isolation cab mounts and seat air suspension.

- Maintain desired cab temperature with automatic temperature controls.

- Pressurized cab with filtered air.

- Reduced sound levels.

- Convenient floor storage tray/lunch box.

- Mid back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod and STIC steer that moves with the seat.

- 76 mm (3 in) wide retractable seat belt.

- Large backlit membrane switches feature LED activation indicators.

- Switches feature ISO symbols for quick function identification.

- Two position rocker switch activates the electro hydraulic park brake.

- Simple side-to-side motion turns machine right or left, minimizing operator movements.

- Easy to operate finger controlled gear selection.

- Smoother, faster cycles help reduce operator fatigue through the use of low effort integrated controls.

Safety First

We are constantly introducing features on our machines in an effort to enhance safety for the operator.

![]()

![]()

![]()

- Railings, ladders and non-slip surfaces enhance technician and operator safety.

- Platform outside of cab allows for seamless cab access, allowing operator to easily maintain three points of contact.

- Optional heated mirrors ensure enhanced visibility for safe operation.

- Standard Cat Vision increases operator awareness around the machine.

- Optional LED lights provide excellent workspace visibility.

- Cab mounted LED warning beacons.

- Reduced vibrations to the operator with isolated cab mounts and seat mounted implement and steering controls.

- Low interior sound levels.

- Pressurized cab with filtered air.

- Standard 76 mm (3 in) seat belts on the operator seat.

Integrated Cat® Technologies

Integrated electronics provide flexible levels of information to both the site and the operator. This integration creates a smart machine and more informed operator, maximizing the productivity of both.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.![]() Take the guesswork out of asset management with Product Link remote monitoring.

Take the guesswork out of asset management with Product Link remote monitoring.![]() Connect directly to the machine for access to a wide range of sensor information and enhanced machine data.

Connect directly to the machine for access to a wide range of sensor information and enhanced machine data.![]()

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.- Intuitive operation and easy navigation with our enhanced user interface.

- Decrease service time by keeping operators informed about machine systems.

- Remote access to information through the easy-to-use VisionLink® interface.

- Maximize uptime by staying informed on machine systems and diagnostic codes.

- Track machine utilization and fuel usage.

- Stay up to date on machine location, service meter hours, and reporting status.

- Create productivity reports with work cycle segmentation.

- Identify operator training needs through productivity data.

- Detailed data logging of machine parameters and diagnostic codes.

- Track machine sensor information with trend analysis and histograms to monitor machine health.

Reduce Environmental Impact

Sustainability is designed and built into our 814K’s features.

- Engine Idle Shutdown and Auto Idle Kickdown can help you save fuel by avoiding unnecessary idling.

- Reduce waste generation with our maintenance free batteries.

- The 814K is built for multiple lives. To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

- The high speed oil change is standard and ensures fast, easy, and secure changing of the engine oil.

Purpose-Built Cat Attachments

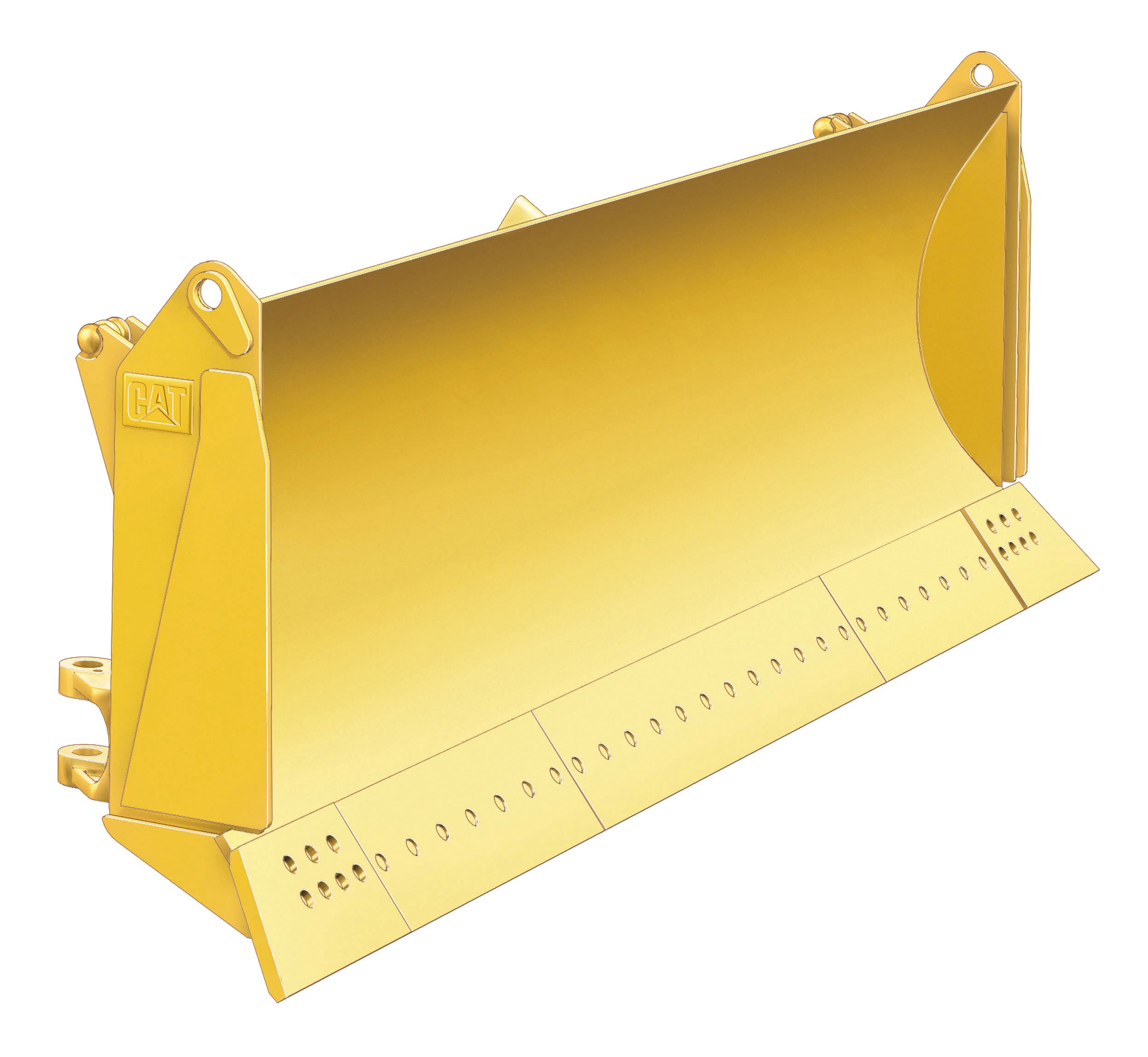

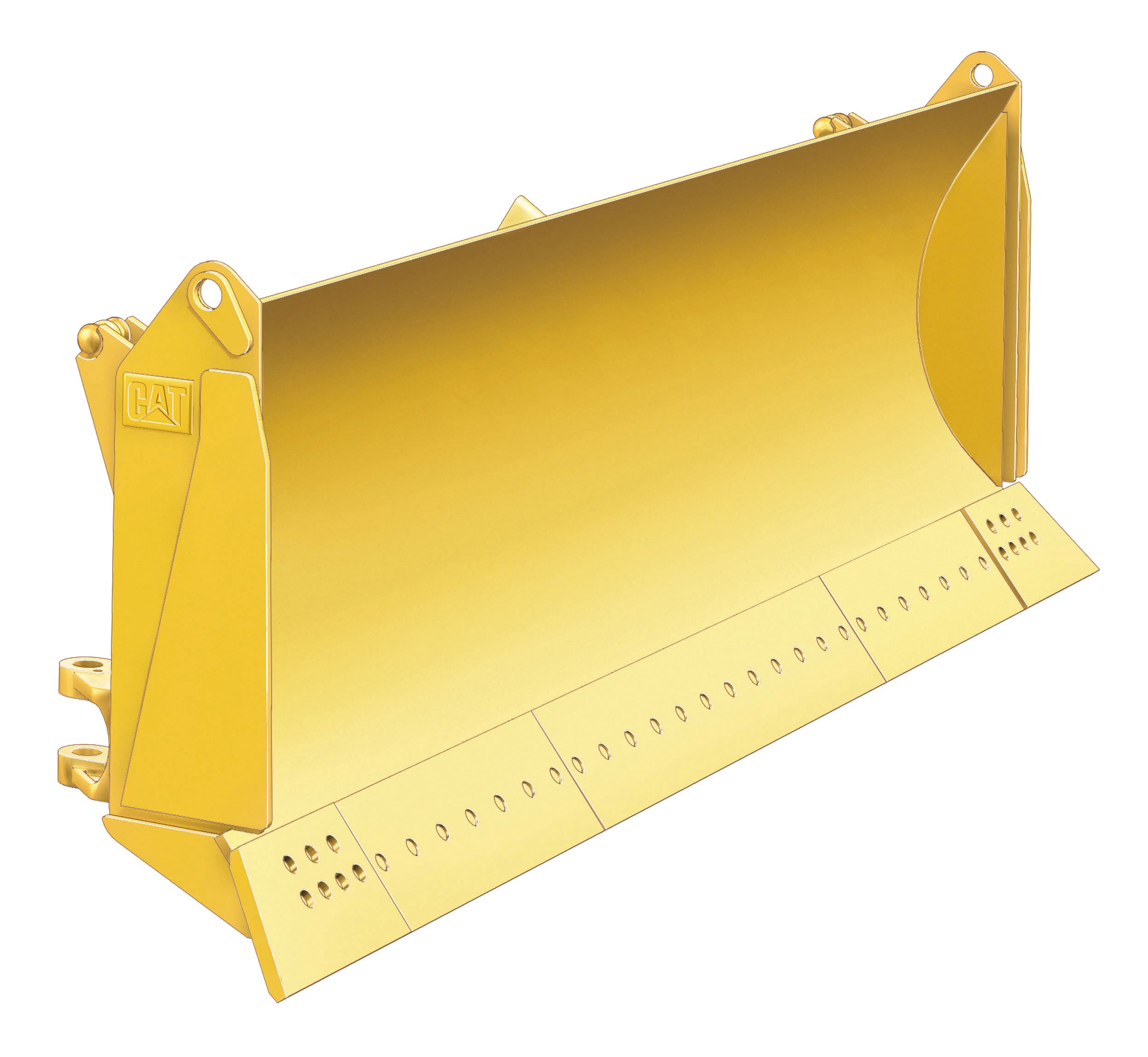

Cat blades are resilient, durable and designed with excellent dozing and rolling characteristics. The straight blade (2.8 m3/3.7 yd3) is designed for production dozing in stockpile material and general earthmoving.

The straight blade (2.8 m3/3.7 yd3) is designed for production dozing in stockpile material and general earthmoving.

![]() The coal blade (10.6 m3/13.8 yd3) is designed for precise and productive dozing while helping to retain load control with increased capacity for lighter materials. Wing angles help retain the load while dozing. This blade is available from Cat Work Tool and Services (CWTS).

The coal blade (10.6 m3/13.8 yd3) is designed for precise and productive dozing while helping to retain load control with increased capacity for lighter materials. Wing angles help retain the load while dozing. This blade is available from Cat Work Tool and Services (CWTS).

![]()

- Capacities and widths are set to achieve increased productivity.

- Spreading design allows for spreading of cover material, as well as dozing of heavier loads.

The straight blade (2.8 m3/3.7 yd3) is designed for production dozing in stockpile material and general earthmoving.

The straight blade (2.8 m3/3.7 yd3) is designed for production dozing in stockpile material and general earthmoving.

Save on Fuel Costs

The 814K has several features to achieve greater fuel efficiency:

- Load Sense Control Hydraulics – Provides only the hydraulic flow required by the implement and steering systems for improved fuel efficiency and greater rimpull.

- Engine – Advanced engine controls maximizes power and efficiency.

- Engine Idle Shutdown – Automatic engine and electrical system shutdown conserves fuel.

- Advanced Productivity Electronic Control Strategy (APECS) – All new APECS transmission controls provides greater momentum on grades and fuel savings by carrying that momentum through the shift points.

Save on Service and Maintenance

We can help you succeed by ensuring your 814K has design features to reduce your downtime.

- Safe and convenient service with ground level or platform access to daily service points.

- Swing-out doors on both sides of the engine compartment provide easy access to important daily service checks.

- Ecology drains for ease of service and prevention of spills.

- Reduce downtime with VIMS system notifications so your operators and technicians can resolve any problems before failure.

- Quick visual inspection and minimize fluid contamination with sight gauges.

- Hydraulic oil cooler, air conditioner condenser, and fuel cooler grouped together for ease of access.

- Side access doors provided for cleanout of the cooling package.

- A new ground level service area includes a Master Disconnect Switch with integrated lock-out/tag-out, DEF purge lamp (Tier 4 Final/Stage IV machines only), circuit breakers, emergency fuel shutoff switch and the jump start receptacle.

- Centralized grease points for convenient maintenance.

Top-Tier Service and Support

A valued partner, your Cat dealer is available whenever you need them.

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

SPECIFICATIONS

- Engine Model C7.1 Cat®

- Transmission Type Cat Planetary Power Shift

- Oscillation Angle ±11°

- Rear Planetary – Oscillating

- Front Planetary – Fixed

- Fuel Tank 782l

- Hydraulic Tank Only 134l

- Transmission 66l

- Differential - Final Drives - Front 100l

- Engine Crankcase 34l

- Differential - Final Drives - Rear 110l

- Ground Clearance 441.4mm

- Ground Clearance - Bumper 852mm

- Height - Top of Cab 4100mm

- Length - With Blade on Ground - Straight Blade 8422mm

- Centerline of Front Axle to Hitch 1850mm

- Wheel Base 3700mm

- Centerline of Rear Axle to Edge of Bumper 2830mm

- Steering System - Circuit Pilot, load sensing

- Steering System - Pump Variable displacement piston

- Net Power 185kW

- Operating Weight 21950kg

- Emissions EPA Tier 4 Final (USA) bzw. Stufe IV (EU)

- Reverse - 1 6.5km/h

- Stroke 135mm

- Reverse - 4 34.6km/h

- Ground to Top of Exhaust Stack 3392mm

- Machine Sound Level (ISO 6395) 111dB(A)

- Cylinders, Double Acting - Left and Right Tilt, Bore and Stroke 101.6 mm × 234 mm (4.0 in × 9.2 in)

- Peak Power Speed - Gross - SAE J1995 213kW

- AC Oil 126ml

- Rated Speed 2200r/min

- Displacement 7.01l

- Maximum Flow at 2,200 rpm 147l/min

- Displacement 7.01l

- Forward - 4 30.5km/h

- Steering Cycle Times - High Idle 3s

- Steering Cycle Times - Low Idle 8.2s

- Machine Sound Level (ISO 6395) 112dB(A)

- Peak Power Speed 1700r/min

- Note (2) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Operating Weight 21950kg

- Relief Valve Setting - Lift/Tilt 22000kPa

- Peak Power Speed 2200r/min

- Stroke 135mm

- Relief Valve Setting - Steering 27600kPa

- Forward - 2 10.1km/h

- Operator Sound Level (ISO 6396) 71dB(A)

- Length of Coal Blade on Ground 7784mm

- Engine Model Cat C7.1

- Length to Front Tire 6356mm

- Peak Power Speed - Net - SAE J1349 186kW

- Note (1) The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Pilot Relief Valve Setting 21000kPa

- Note (3) The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Forward - 3 17.6km/h

- Engine Model Cat C7.1

- Peak Torque - 1,400 rpm 1219N·m

- Note (3) The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Torque Rise 52%

- Emissions Brazil MAR-1 and China Nonroad Stage III, equivalent to U.S. EPA Tier 3/EU Stage IIIA

- Peak Power Speed - Gross - SAE J1995 212kW

- Lift/Tilt System Variable displacement piston

- Operator Sound Level (ISO 6396) 70dB(A)

- Operating Weight 21671kg

- Ground to Top of Hood 2614mm

- Bore 105mm

- Note (2) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Operator Sound Level (ISO 6396) 71dB(A)

- Note (1) The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Oil Renewal System (ORS) N. z.

- Total Steering Angle 72°

- Brakes Single Disc Wet (enclosed) 4 WHL

- Rated Speed 2200r/min

- Pilot System Open center, fixed displacement gear

- Machine Sound Level (ISO 6395) 110dB(A)

- Note (3) The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

- AC Refrigerant 19hg

- Maximum Flow at 2,200 rpm 89l/min

- Note (2) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Reverse - 3 20.1km/h

- Hydraulic System - Implement/Steering 129l

- Ground to Top of Beacon 3994mm

- Machine Sound Level (ISO 6395) 109dB(A)

- Cooling Systems - Brazil MAR-1 and China Nonroad Stage III, equivalent to Tier 3/Stage IIIA 73l

- Forward - 1 5.7km/h

- Bore 105mm

- Torque Rise 26%

- Peak Power Speed - Net - SAE J1349 185kW

- Operator Sound Level (ISO 6396) 70dB(A)

- Note (1) The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Cooling Systems - Tier 4 Final/Stage IV 81l

- Peak Torque - 1,400 rpm 1016N·m

- Reverse - 2 11.5km/h

- Note (2) Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

- Cylinders, Double Acting - Lift, Bore and Stroke 120 mm × 915 mm (4.7 in × 36.0 in)

- Hydraulic System - Steering N. z.

- Lift/Tilt System - Circuit Pilot operated LS valve with EH

- Note (3) The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

- Diesel Exhaust Fluid Tank 16l

- Hydraulic System - Implement N. z.

- Note (1) The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS