US

METRIC

6015B

KEY SPECS

- Engine Output - SAE J1995 606kW

- Bucket Payload 14.6t

- Operating Weight 140t

OVERVIEW

BENEFITS

-

More than 15% Higher Productivity

- With the most powerful engine in its class, the 6015B provides class-leading cycle times, larger payload capacity and unmatched productivity. The 6015B also has class-leading tool carrying capacity to work across the spectrum of activities most commonly found in heavy construction, quarry and aggregate, and demolition.

-

More than 20% Better Fuel Efficiency

- Delivering at least a 20% fuel efficiency advantage over current shovels in its class, the Cat 6015B cuts fuel costs for every ton moved.

-

1 Pass Advantage

- The Cat 6015B comes standard with an 8.1 m3 (10.6 yd3 ) bucket, giving it a full one-pass advantage per cycle over the leading standard equipped shovels in its class. Faster cycle times and bigger loads per bucket add up to more trucks loaded per shift and top production efficiency.

FEATURES AT A GLANCE

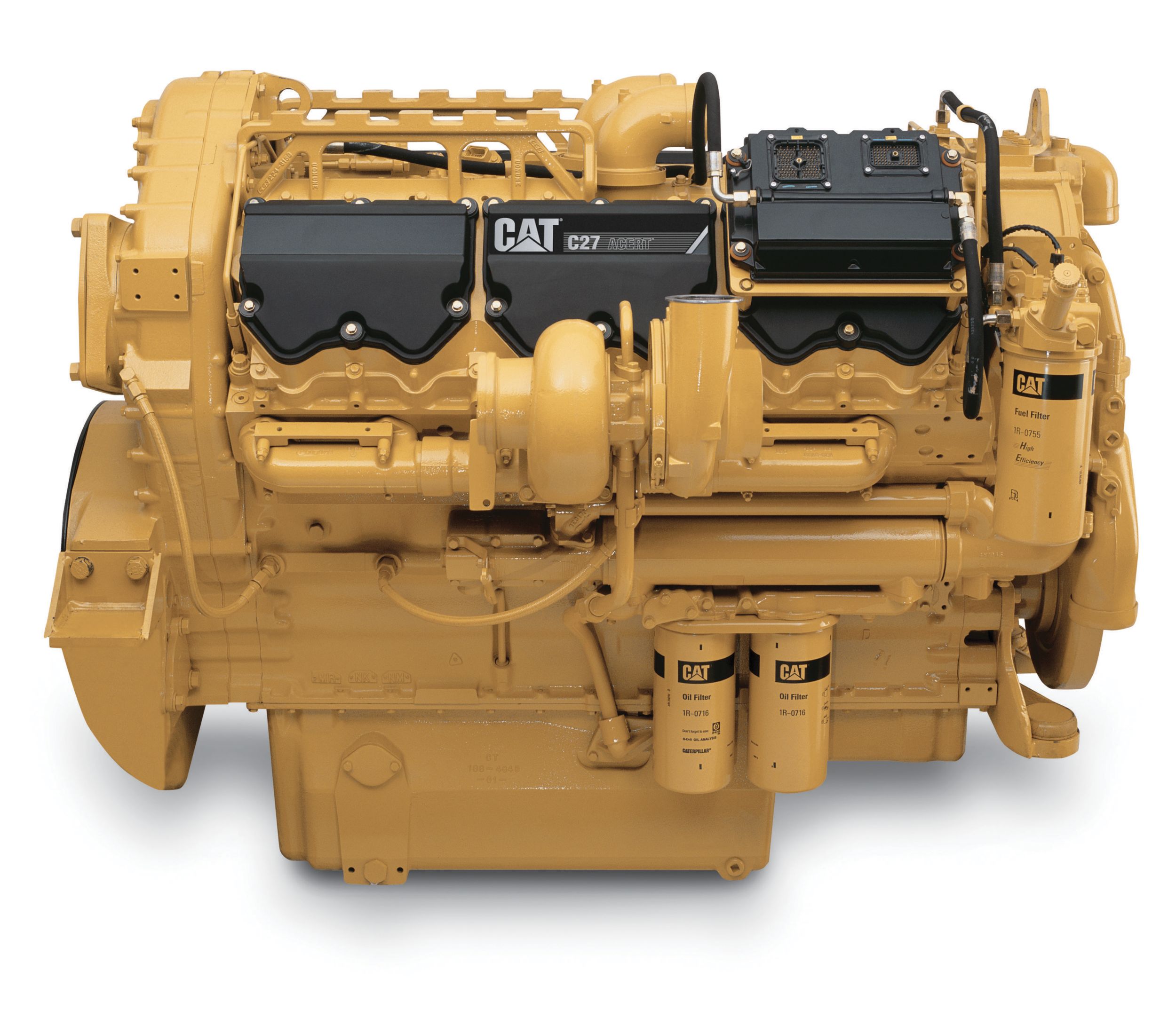

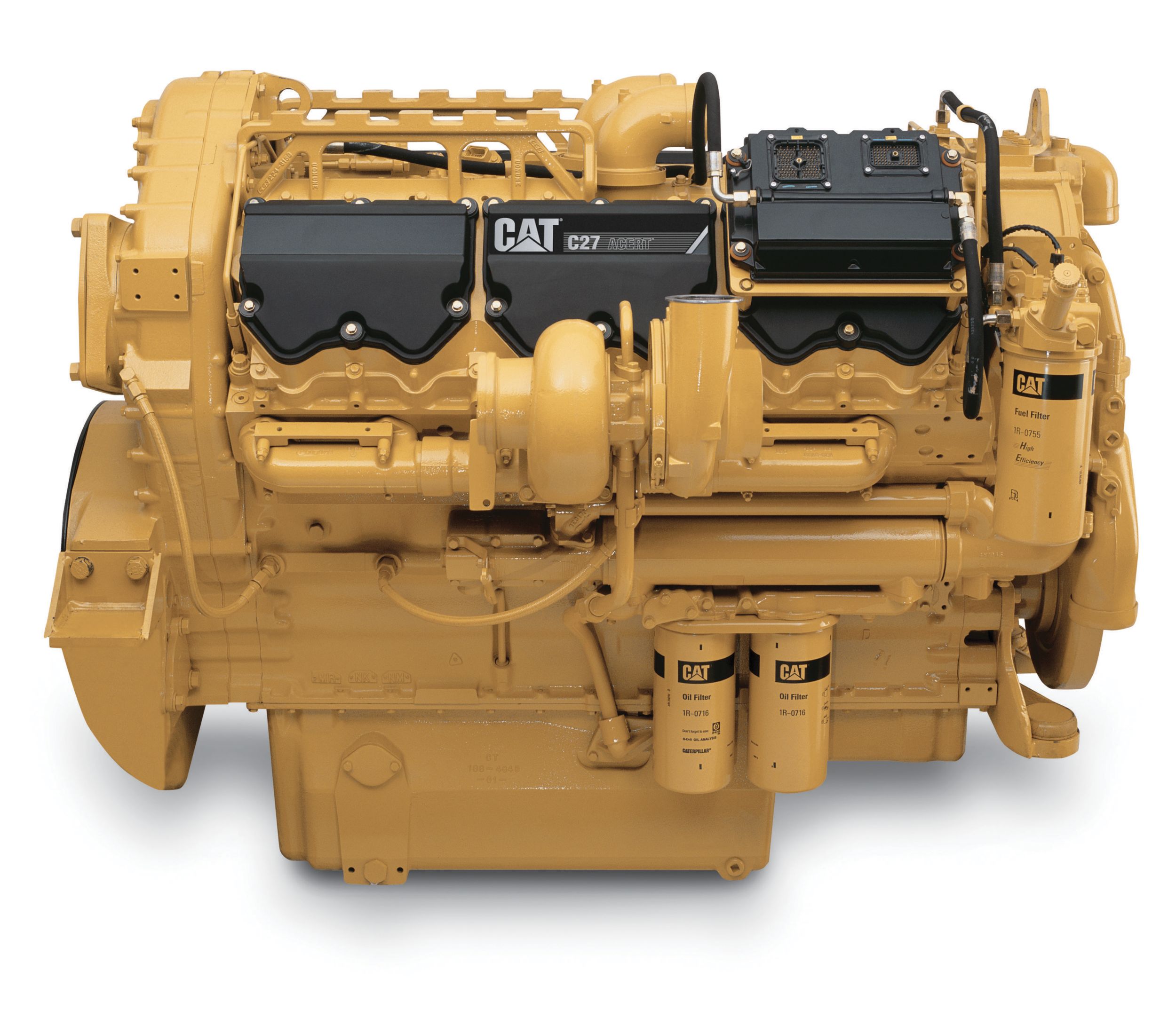

Powerful Engine

Offering 606 kW (813 hp) of rated power via its single C27 engine, the 6015B is capable of providing class-leading cycle times and unmatched productivity.

![]() The Cat C27 engine delivers power and reliability, ensuring top performance, high productivity, and exceptional service life. Its durability has been proven in heavy construction, quarry/aggregate, and mining applications alike; the versatility required of a 100 tonne (110 ton) hydraulic shovel.

The Cat C27 engine delivers power and reliability, ensuring top performance, high productivity, and exceptional service life. Its durability has been proven in heavy construction, quarry/aggregate, and mining applications alike; the versatility required of a 100 tonne (110 ton) hydraulic shovel.

![]() The development of our new engine technology began with the search for a better way to reduce diesel engine emissions, and culminated in a revolutionary engine design breakthrough that burns fuel more precisely than ever before. Lower combustion temperatures reduce emissions and prolong the life of lighter, more power-dense engine platforms. It also varies the injection timing based on factors like engine load and speed for optimum performance under a wide range of operating conditions, including mining.

The development of our new engine technology began with the search for a better way to reduce diesel engine emissions, and culminated in a revolutionary engine design breakthrough that burns fuel more precisely than ever before. Lower combustion temperatures reduce emissions and prolong the life of lighter, more power-dense engine platforms. It also varies the injection timing based on factors like engine load and speed for optimum performance under a wide range of operating conditions, including mining.

![]() Our engines are only as good as the service and support that stand behind them. Highly trained and experienced service technicians at your local Cat dealership are ready with whatever you need, wherever and whenever you need it. They know the Cat C27 ACERT engine inside and out, so they can promptly diagnose issues and keep your 6015B running at peak performance.

Our engines are only as good as the service and support that stand behind them. Highly trained and experienced service technicians at your local Cat dealership are ready with whatever you need, wherever and whenever you need it. They know the Cat C27 ACERT engine inside and out, so they can promptly diagnose issues and keep your 6015B running at peak performance.

![]()

Optimized Truck Match

Standard equipped with a large, 8.1 m3 (10.6 yd3) bucket, the 6015B is designed to optimally pass popular Cat 773, 775, and 777 trucks, at 4, 5, and 7 passes, respectively. This is a one pass advantage over leading standard equipped shovels in its class. When consistently achieved, the result is more material moved, and greater profit.

![]() With its ability to pair with trucks most commonly found in heavy construction, quarry/aggregate, and small to mid-size mining applications across the globe, 6015B demonstrates the versatility required of a 100 tonne (110 ton) shovel to be an appropriate and productive fit for any of these environments.

With its ability to pair with trucks most commonly found in heavy construction, quarry/aggregate, and small to mid-size mining applications across the globe, 6015B demonstrates the versatility required of a 100 tonne (110 ton) shovel to be an appropriate and productive fit for any of these environments.

![]()

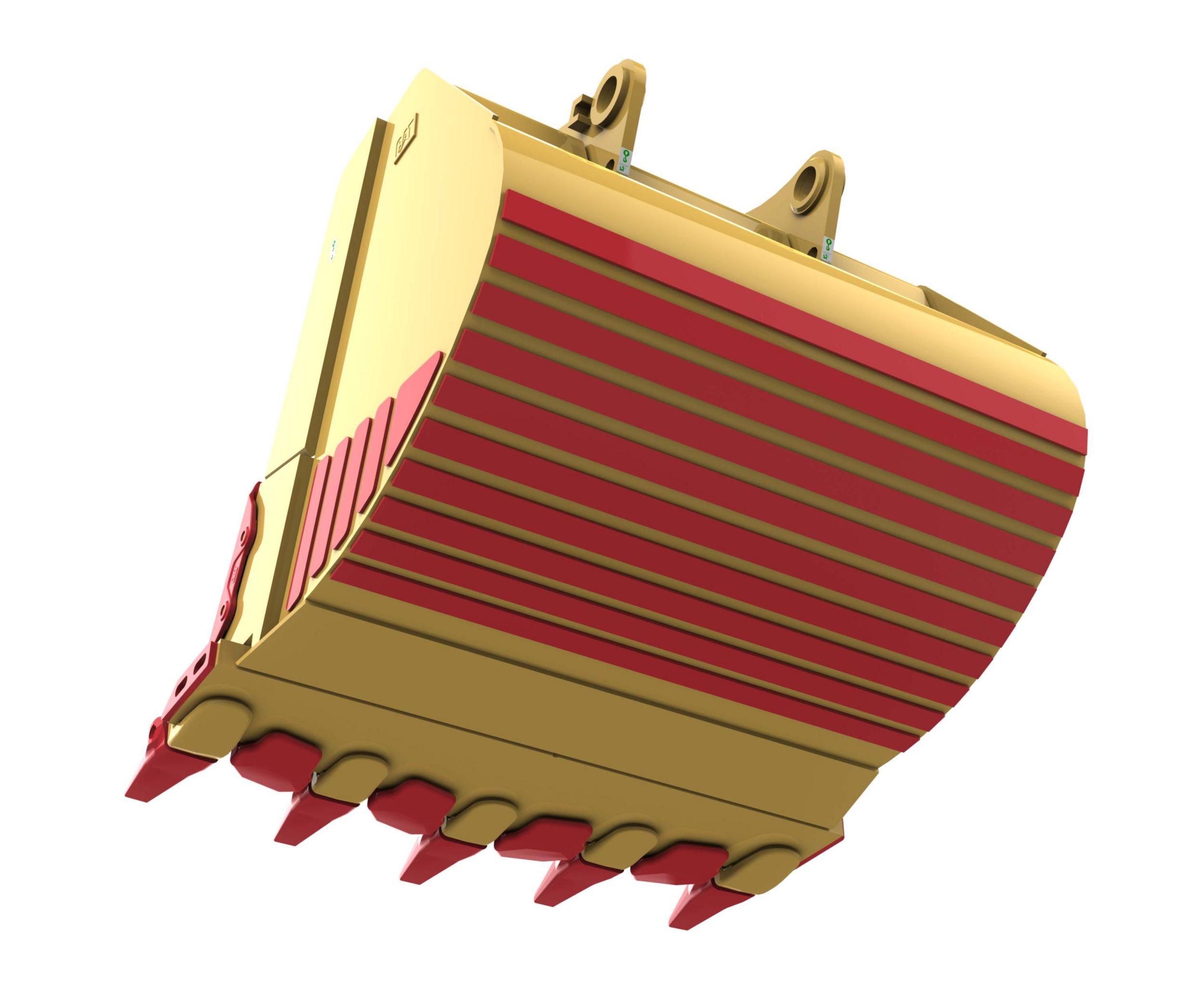

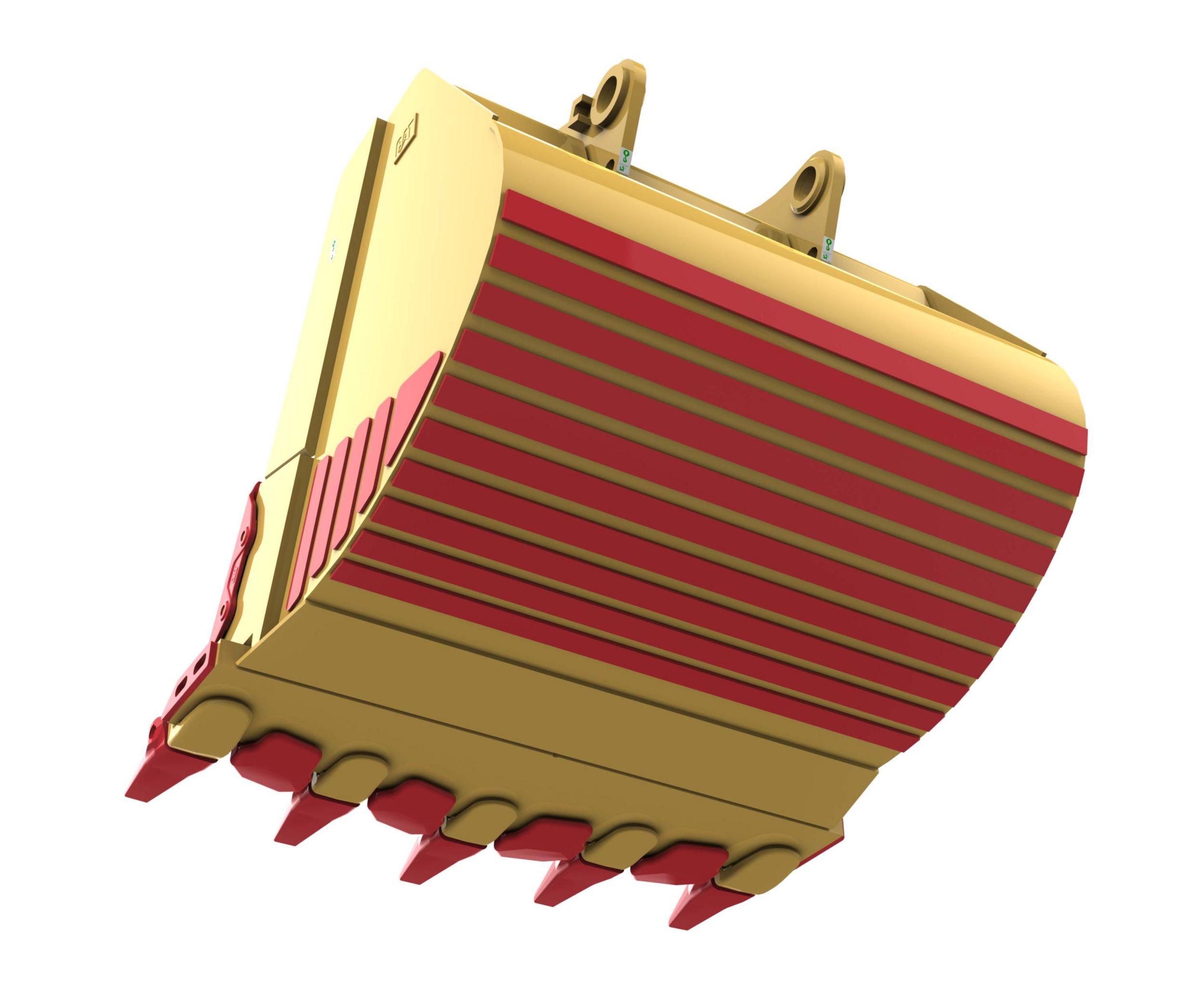

Productivity Enhancing Cat Buckets and G.E.T.

Cat buckets are designed to match your Cat 6015B mining shovel, providing optimum payload and machine efficiency while protecting your investment. Bucket wear surfaces are armored with replaceable wear materials to extend the life of your bucket. Cat buckets are easy to rebuild, with all parts available through your Cat dealer. Trust Cat to give you long service life without adding excessive weight.

General Duty buckets are sized for low density materials, providing maximum payload in general duty applications such as top soil.

General Duty buckets are sized for low density materials, providing maximum payload in general duty applications such as top soil.

![]() Heavy Duty buckets are suited for less dense rock and soils. The Heavy Duty wear package includes lip shrouds to fully guard the bucket lip and has hardened wear bars in the highest wear areas.

Heavy Duty buckets are suited for less dense rock and soils. The Heavy Duty wear package includes lip shrouds to fully guard the bucket lip and has hardened wear bars in the highest wear areas.

![]() Extreme Duty buckets are the most heavily guarded for use in dense rock and aggressive digging conditions. It features lip shrouds as well as hardened wear material across the entire bucket surface.

Extreme Duty buckets are the most heavily guarded for use in dense rock and aggressive digging conditions. It features lip shrouds as well as hardened wear material across the entire bucket surface.

![]() The Coal bucket for the 6015B uses the General Duty wear package with guarding in the most critical areas and it's sized to match the density of coal to provide optimum productivity.

The Coal bucket for the 6015B uses the General Duty wear package with guarding in the most critical areas and it's sized to match the density of coal to provide optimum productivity.

![]() Increase your operational efficiency and productivity with C70 hammerless Cat G.E.T. designed specifically for the 6015B hydraulic mining shovel. By designing our own G.E.T. in-house, we are able to take a production focus, rather than a component focus, to optimize performance across the entire machine. And like all Cat G.E.T., it is fully supported by your local Cat dealer.

Increase your operational efficiency and productivity with C70 hammerless Cat G.E.T. designed specifically for the 6015B hydraulic mining shovel. By designing our own G.E.T. in-house, we are able to take a production focus, rather than a component focus, to optimize performance across the entire machine. And like all Cat G.E.T., it is fully supported by your local Cat dealer.![]()

- Sized to match the 6015B hydraulic shovel and your application.

- Protected with high abrasion materials matched to the wear characteristics of your application.

- Rebuildable, with all wear components (shown below in red) available as service parts.

General Duty buckets are sized for low density materials, providing maximum payload in general duty applications such as top soil.

General Duty buckets are sized for low density materials, providing maximum payload in general duty applications such as top soil.

- Increased uptime: Simple 180 degree turn to lock and unlock.

- Safe installation and removal: No pins to drive out; retainer is built into the tip.

- Fast and easy change-outs: No special tools are required to service the hammerless system.

- Simple installation: No assembly required.

Proven Cat Cab Design

A modified version of the Cat HEX cab, the 6015B cab has literally logged hundreds of thousands of hours digging in tough applications across the globe. You can rest assured that it will meet the demands of your application, as well as the comfort and safety requirements of your operators.

![]()

![]()

- Large, wide windows provide excellent all-around visibility. – Retractable front windshield made of standard laminated glass provides large viewing area. – Lower front window provides view of the tracks. – Large, right side polycarbonate window provides good visibility across the machine. – Tempered glass upper door window slides open for excellent ventilation. – Polycarbonate skylight provides unobstructed upward view.

- Multiple strategically positioned and high-powered lights for maximum illumination of the digging area in dark conditions (Optionally available in LED).

- Heavy-duty wipers ensure good visibility in inclement weather conditions.

- Extremely quiet and fully pressurized cab environment.

- Fully adjustable suspension seat provides height and weight adjustments, lumbar support, wide arm/wrist rests and wide retractable seat belt for full operator comfort and support.

- Ergonomic controls with adjustable joystick console height, independent of the seat, to operator preference.

- A new seven inch multipurpose color touch screen display dramatically simplifies the operator interface. – Intuitive navigation with in-language text enables operators to modify certain machine operating parameters and monitor machine conditions literally at the touch of their fingers.

- Fully automatic climate control system with air conditioner, heater, and defroster, maintains constant cab temperature for comfortable operation in any weather condition.

- Double wall pressed cab shell and platform are mounted to the cab riser with resilient mounts to reduce noise, vibration and operator fatigue.

- Responsive electro-hydraulic controls provide sure, precise maneuvering for high production capability and minimized operator fatigue.

- No hydraulic lines are present in the cab for a cool, clean, quiet, and odorless environment.

Cat Undercarriage Design

Cat exclusive Positive Pin Retention (PPR) Sealed and Greased Track design resists pin walking and link cracking for reliable sealing and maximum track life.

![]()

![]()

![]()

- Resists end-play generation and link movement on the pin.

- Tightly controls seal motion for long internal pin/bushing wear life.

- Resists fatigue and crack formation with redesigned, stronger track links.

- Even idler slide wear and extended component life result from the floating push tube.

- Low wear drive system via induction hardened and high quantity of sprocket teeth.

- Full track guards are optionally available for even greater protection of bottom rollers.

- Automatic track tensioning system is a simplified design that requires no manual adjustment.

- PPR tracks are easily serviced with a master joint. Allows for easy removal and installation of undercarriage.

- Eliminates unnecessary wear and assists in easier track tensioning via three carrier rollers.

- Exceptional track guidance via standard track guides the entire length of the crawler.

- Travel motors and gearboxes are well protected by robust steel covers, with integrated service doors for easy service access.

Robust Structures

To extend service life and ensure that your 6015B keeps producing, our structures are designed for durability and dependability. Extended performance in the harsh digging conditions you face daily is accomplished through selection of high-strength steels and rugged castings, joined and thermally stress-relieved to create a reliable external shell.![]() The 6015B boom and stick utilize high-strength steel and rugged castings, that are joined and thermally stress relieved, for optimum structural life and resistance to impact and wear in difficult digging conditions.

The 6015B boom and stick utilize high-strength steel and rugged castings, that are joined and thermally stress relieved, for optimum structural life and resistance to impact and wear in difficult digging conditions.![]() Providing superior stability, extending component life, and ultimately improving machine uptime, our swing system includes a unique cross roller bearing, with sealed internal gearing, connected to an automatic lubrication system.

Providing superior stability, extending component life, and ultimately improving machine uptime, our swing system includes a unique cross roller bearing, with sealed internal gearing, connected to an automatic lubrication system.

![]() Exceptional structural strength and durability is afforded by mounting the swing bearing directly to the 6015B carbody, eliminating collar welds.

Exceptional structural strength and durability is afforded by mounting the swing bearing directly to the 6015B carbody, eliminating collar welds.

![]() Protecting against surface wear, while preserving structural toughness in the main bearing body, 6015B swing bearing rings are made of specially heat-treated steel, and raceways are induction hardened.

Protecting against surface wear, while preserving structural toughness in the main bearing body, 6015B swing bearing rings are made of specially heat-treated steel, and raceways are induction hardened.

![]() All 6015B structures have been fully tested and validated at our state-of-the-art proving ground in Tucson, AZ (USA).

All 6015B structures have been fully tested and validated at our state-of-the-art proving ground in Tucson, AZ (USA).

![]()

- Manufactured from high-strength steel for durability.

- Full penetration, profiled and ground welds at critical junctures.

- MT, UT, and X-ray inspections on select welds ensure quality.

- Box-section design provides unsurpassed rigidity and strength.

- Thermally stress relieved structures reduce residual stresses for longer structural life.

- Heat treated castings are used in boom foot area to handle high force boom loads.

- Heavy duty castings in high load areas add exceptional strength and durability.

Fuel Efficiency Technologies

Proprietary Cat integrated engine control technologies keep the engine running at or near the rated speed to maintain an optimized balance of power and fuel efficiency. This technology prevents large drops in engine speed, followed by over speeds, often observed in older equipment. It provides the following benefits:![]()

- Estimates fuel requirements, based on engine speed and torque, and needed machine torque, based on hydraulic load (pumps and fan). This technology ensures faster and more consistent engine regulation by preventing lug, which, in turn, reduces fuel consumption.

- Reduces hydraulic pump output to prevent engine lug, based on available engine torque, desired engine speed, actual engine speed, and estimated hydraulic load. This technology provides power to the machine functions that need it to move material quickly and efficiently.

Closed-Loop Swing System

Kinetic energy captured during the swing motion is fed back into the system during deceleration, providing more power to drive the main and auxiliary pumps. Energy is saved during deceleration, because braking occurs hydrostatically with pump displacement controls, as opposed to throttling flow through breaking valves as in open circuit swing systems.

![]() Energy is saved during swing via speed control, ensuring that only the minimum necessary oil flow is utilized at any given time, and providing smooth acceleration and deceleration for fast cycles.

Energy is saved during swing via speed control, ensuring that only the minimum necessary oil flow is utilized at any given time, and providing smooth acceleration and deceleration for fast cycles.

![]()

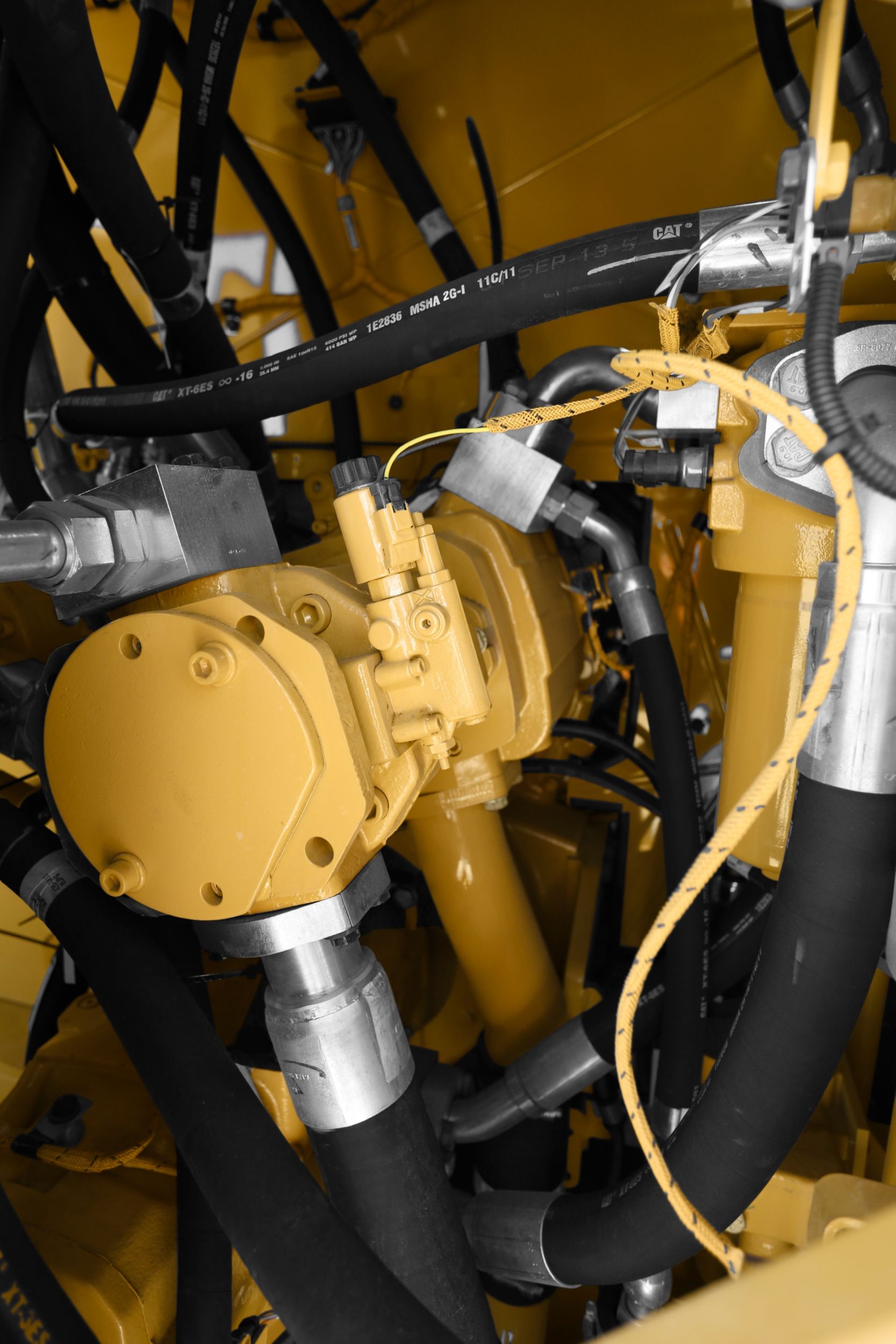

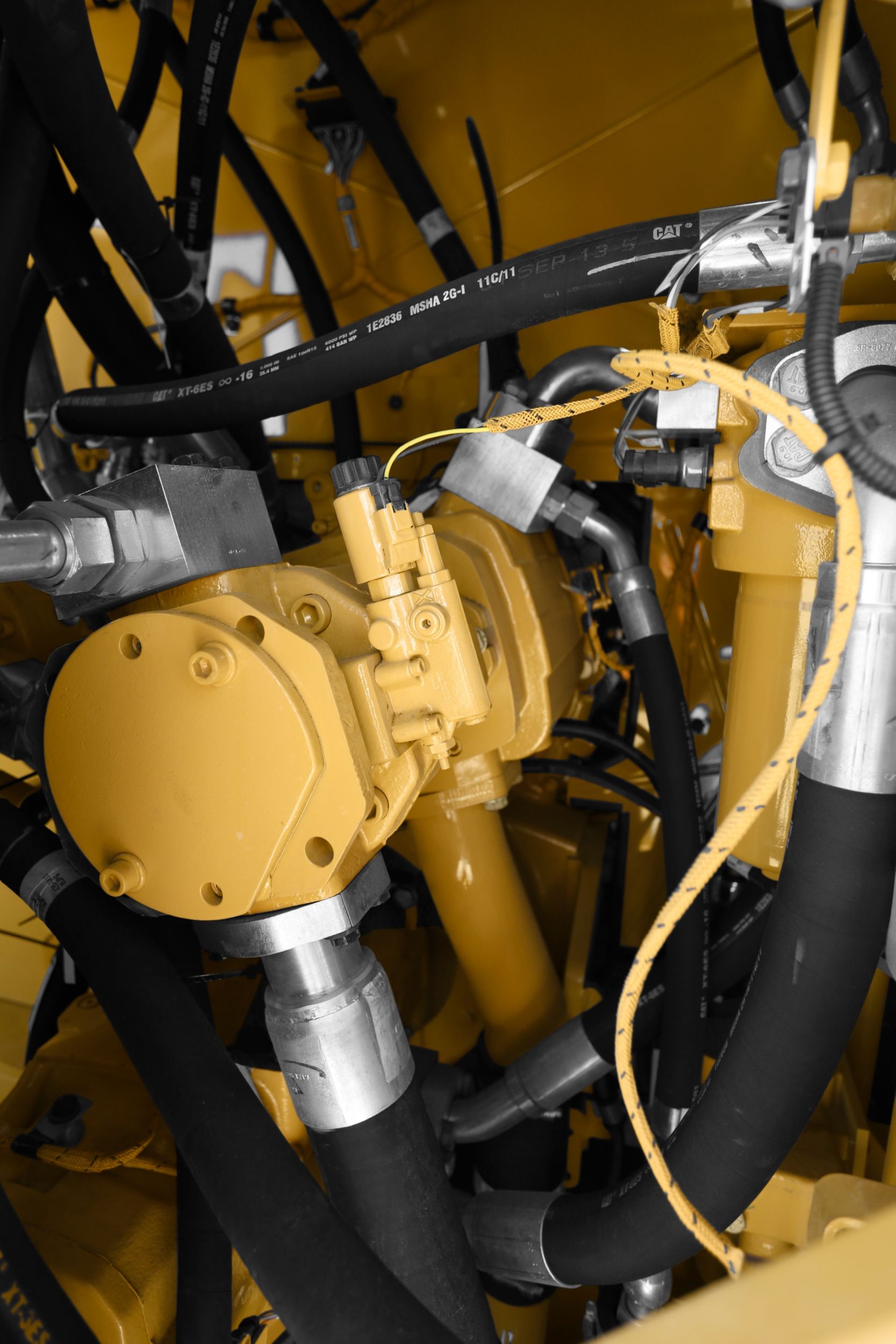

Efficient Hydraulic System

More efficient hydraulic pump utilization, reduced energy losses, and increased fuel savings are realized with our innovative, automatic flow proportioning technology.![]() Smooth, efficient operation, and controllability is afforded by our Cat Proportional Priority Pressure Compensating (PPPC) technology. PPPC ensures that flow is proportional, according to demands, so individual functions – boom, stick, and bucket – are automatically prioritized during simultaneous operations.

Smooth, efficient operation, and controllability is afforded by our Cat Proportional Priority Pressure Compensating (PPPC) technology. PPPC ensures that flow is proportional, according to demands, so individual functions – boom, stick, and bucket – are automatically prioritized during simultaneous operations.

![]() Maximized hydraulic efficiency is delivered via our flow-on-demand system, designed with four pumps; three for implement and travel, and one for swing. Pressure and flow compensation deliver only as much flow as needed to reduce heat build-up and component wear.

Maximized hydraulic efficiency is delivered via our flow-on-demand system, designed with four pumps; three for implement and travel, and one for swing. Pressure and flow compensation deliver only as much flow as needed to reduce heat build-up and component wear.

![]() The hydraulic system design has been optimized for peak performance and reliability, featuring a newly designed filtration system.

The hydraulic system design has been optimized for peak performance and reliability, featuring a newly designed filtration system. To maximize hydraulic efficiency, our oil cooling system is independent of engine cooling, providing cooling on demand.

To maximize hydraulic efficiency, our oil cooling system is independent of engine cooling, providing cooling on demand.

![]() Resulting in greater fuel economy, the temperature controlled variable speed fan provides cooling on demand to maintain optimum hydraulic fluid temperature.

Resulting in greater fuel economy, the temperature controlled variable speed fan provides cooling on demand to maintain optimum hydraulic fluid temperature.

- Additional fuel savings resulting from boom float feature, which regenerates boom oil for reduced engine demand and improved energy efficiency.

- Machine comes equipped with standard high-pressure and return oil filtration.

- A separate kidney loop provides continuous filtration and optimum oil cleanliness at all times, supporting the hydraulic system.

To maximize hydraulic efficiency, our oil cooling system is independent of engine cooling, providing cooling on demand.

To maximize hydraulic efficiency, our oil cooling system is independent of engine cooling, providing cooling on demand.

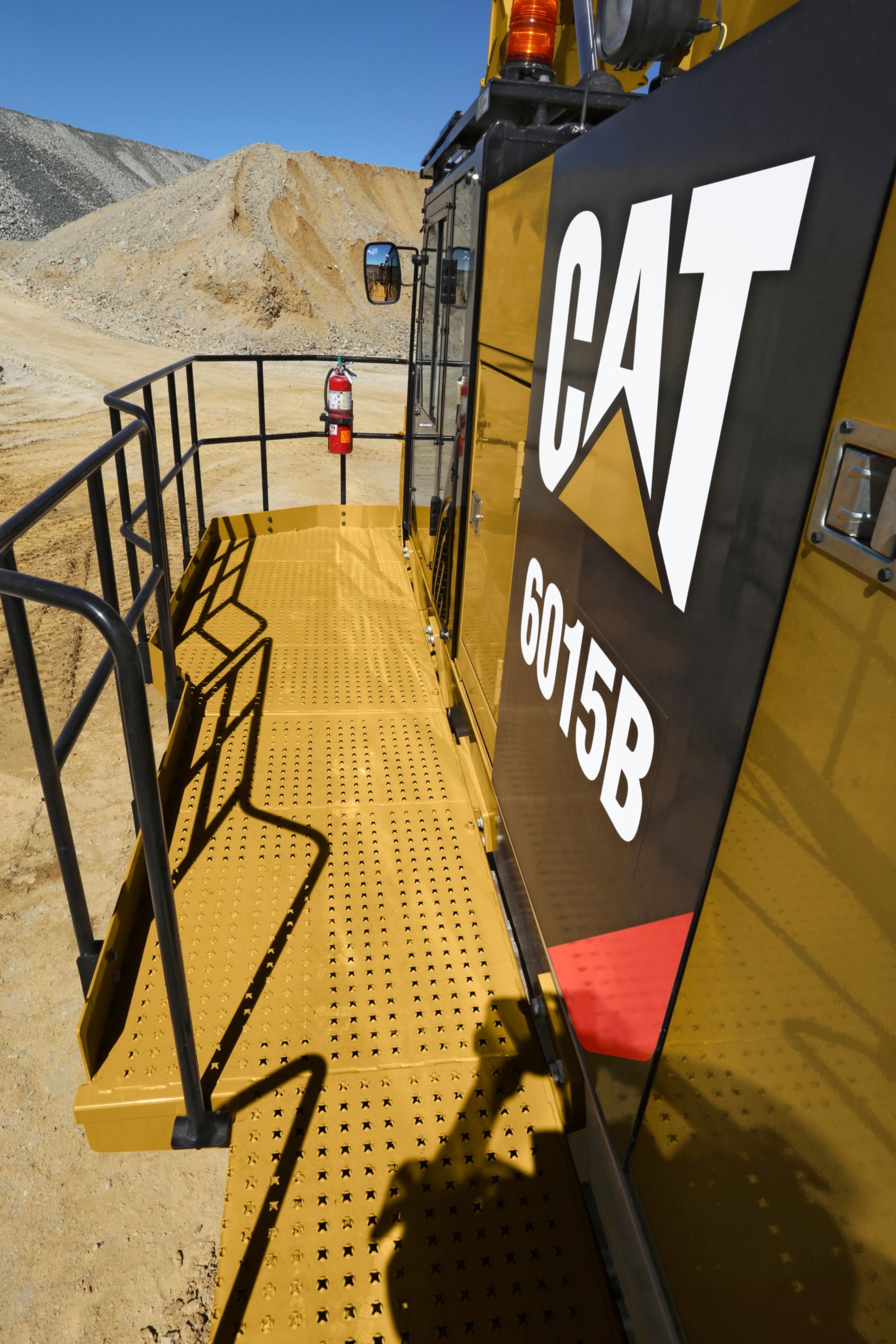

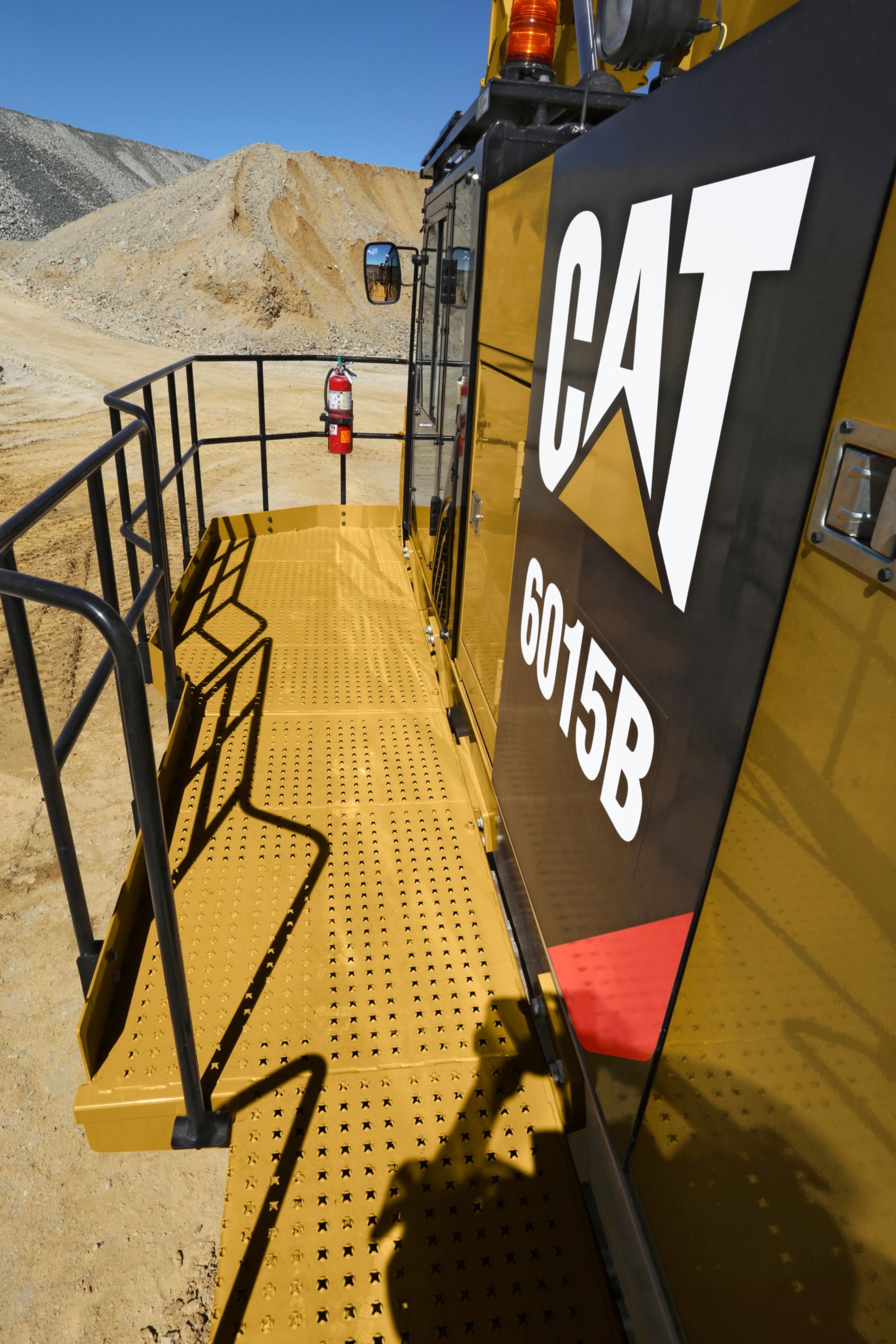

Safety Enhancements

Sharing your commitment to safety, and driven by our commitment to Zero Harm, we work tirelessly to design the safest machines possible to protect your most important asset; your employees.

Some examples of the safety-enhancing features of the Cat 6015B hydraulic mining shovel include the following:

Some examples of the safety-enhancing features of the Cat 6015B hydraulic mining shovel include the following:

![]()

![]()

Some examples of the safety-enhancing features of the Cat 6015B hydraulic mining shovel include the following:

Some examples of the safety-enhancing features of the Cat 6015B hydraulic mining shovel include the following:

- Optimized operator situational awareness and safe machine positioning and truck loading via excellent cab visibility and large, ideally positioned mirrors.

- Multiple egress points for safe exit to the side or front of machine.

- Cab equipped with emergency hammer for quick escape and ready access to emergency ladder.

- Numerous, optimally positioned lights for ample visibility during operation in dark conditions.

- FOPS certified cab with safety glass windshield.

- Ergonomic placement of cab door handle to prevent bending down, and risk of injury, to enter cab.

- Wide crosswalk made of extruded tread plates provides safer service access to full width of machine, including hydraulics, engine service doors and engine/pump room.

- Safe movement about the machine via wide and slip-resistant walkways, limited walkway elevation changes (steps up/down), and minimized trip hazards.

- Grab irons and steps provide operator and maintenance personnel with three points of contact at all times.

- Quick exit from machine during emergency facilitated by three means of egress.

- Optional 45 degree boarding ladder.

- Ability to lower boarding ladder from ground level in case of an emergency.

- A bulkhead separates the pump room from the engine compartment for safer containment of hydraulic oils.

- Improved wire and hose guarding for added safety.

- Safe electrical maintenance facilitated by battery disconnect switch.

- Ground level, engine and pump room, and cab access to engine kill switches allows quick shutoff in emergency situations.

Cat Technology Solutions

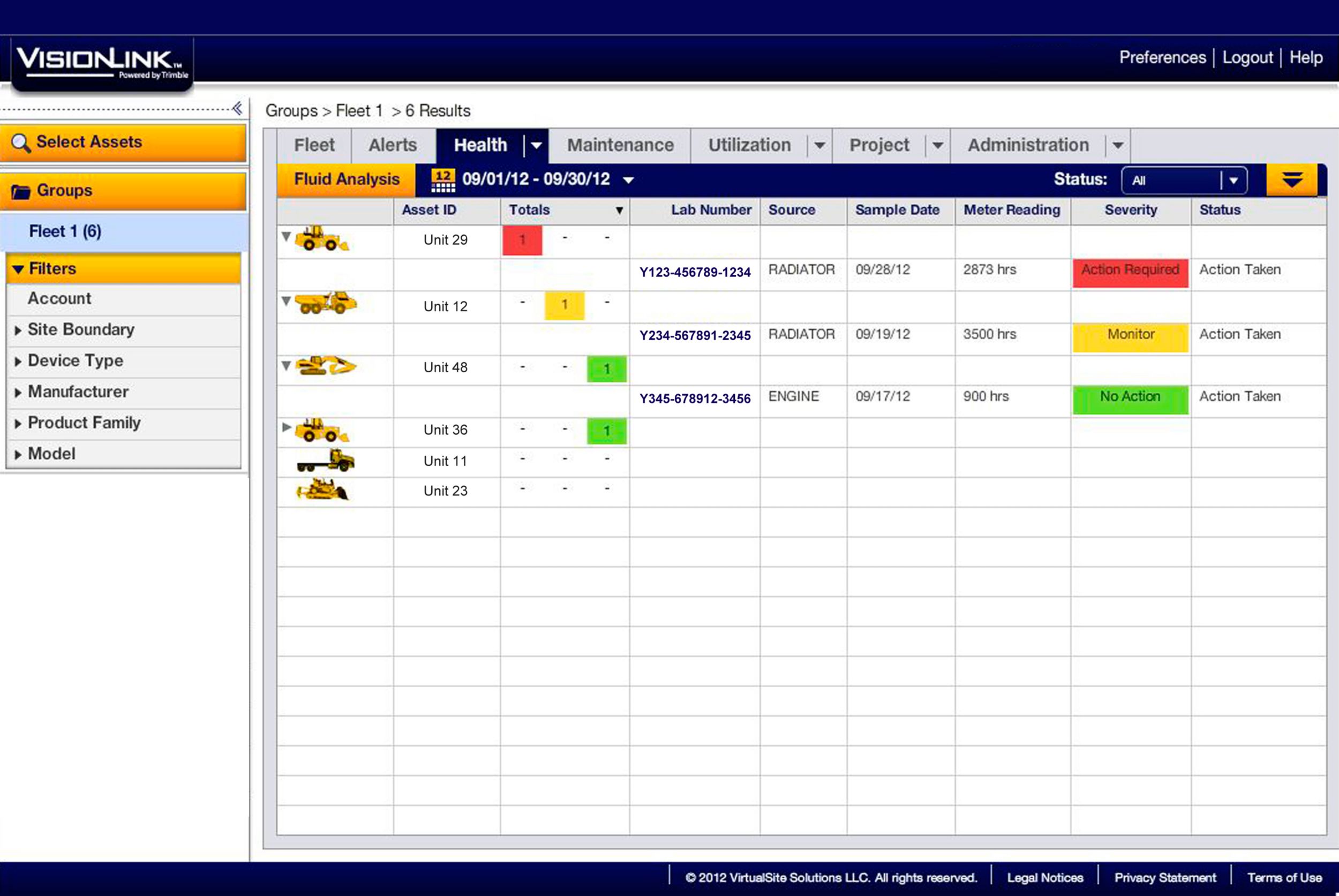

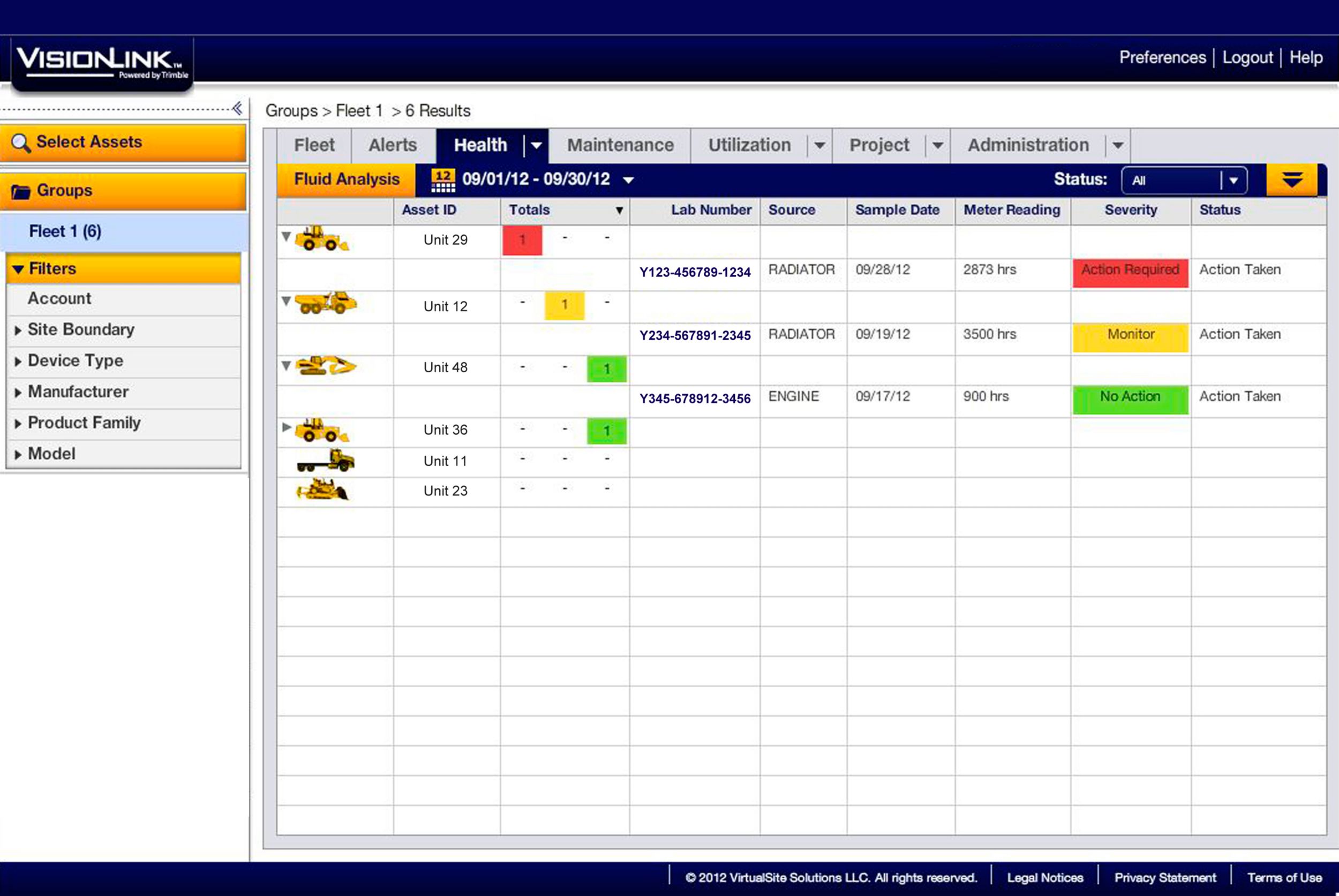

Aimed at enhancing the productivity and profitability of your 6015B hydraulic shovel, we currently offer optional Cat MineStar™, Product Link™, and VIMS™ solutions, to meet your site specific needs.

Take the guesswork out of asset management with Product Link remote monitoring.

Take the guesswork out of asset management with Product Link remote monitoring. Connect directly to the machine for access to a wide range of sensor information and enhanced machine data.

Connect directly to the machine for access to a wide range of sensor information and enhanced machine data. Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more.

Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more.

![]() The Cat 6015B is “MineStar ready,” capable of utilizing four of the Cat MineStar System capability sets; Health is a fully integrated option, while Fleet, Terrain for Loading, and Detect are retrofit options.

The Cat 6015B is “MineStar ready,” capable of utilizing four of the Cat MineStar System capability sets; Health is a fully integrated option, while Fleet, Terrain for Loading, and Detect are retrofit options.![]() Please speak to your local dealer for more information on MineStar for the 6015B.

Please speak to your local dealer for more information on MineStar for the 6015B.

![]()

Take the guesswork out of asset management with Product Link remote monitoring.

Take the guesswork out of asset management with Product Link remote monitoring.- Remote access to information through the easy-to-use VisionLink® interface.

- Maximize uptime by staying informed on machine systems and diagnostic codes.

- Track machine with utilization, fuel usage, and payload summaries (when used with equipped truck).

- Stay up to date on machine location, service meter hours, and reporting status.

Connect directly to the machine for access to a wide range of sensor information and enhanced machine data.

Connect directly to the machine for access to a wide range of sensor information and enhanced machine data.- Detailed data logging of machine parameters and diagnostic codes.

- Track machine sensor information with trend analysis and histograms to monitor machine health.

Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more.

Helping you achieve your goals for enhanced mine site safety, improved efficiency, reduced operating costs, and greater profitability, the Cat MineStar System provides the most comprehensive suite of mining technology products in the industry. It consists of a number of configurable capability sets – Fleet, Terrain, Detect, Health, and Command – that allow you to scale the system to your mine site needs. Cat MineStar System helps you manage everything from material tracking to sophisticated real-time fleet management, machine health systems, autonomous equipment, and more.

- Health – Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities with a wide range of diagnostic, analytic and reporting tools.

- Fleet – Fleet provides real-time machine tracking, assignment and productivity management, providing a comprehensive overview of all your asset operations from anywhere in the world.

- Terrain – Terrain enables high-precision management of drilling, dragline, grading and loading operations through the use of guidance technology. It increases machine productivity and provides you real-time feedback for improved efficiency.

- Detect – Detect provides equipment operators with enhanced awareness for increased site safety, using a combination of radars, an in-cab display, and multiple cameras.

Emissions Technology

The C27 engine on the 6015B hydraulic shovel meets Tier 4 Final emission standards and can be counted on to work productively and economically in heavy construction, quarry/aggregate, and mining applications. It delivers the power and torque needed for optimal performance and fast cycles.

The 6015B meets Tier 4 Final emission standards in the United States and Canada using:

The 6015B meets Tier 4 Final emission standards in the United States and Canada using:![]() Ultra Low Sulfur Diesel (ULSD) Fuel and Low Ash Oil are required. Diesel exhaust fluid is not required.

Ultra Low Sulfur Diesel (ULSD) Fuel and Low Ash Oil are required. Diesel exhaust fluid is not required.

![]() There are two engine arrangements available for the market outside of the U.S. and Canada; a China NR III certified offering that is Tier 2 equivalent, as well as an optimized fuel consumption offering that is Tier 1 equivalent.

There are two engine arrangements available for the market outside of the U.S. and Canada; a China NR III certified offering that is Tier 2 equivalent, as well as an optimized fuel consumption offering that is Tier 1 equivalent.

![]()

The 6015B meets Tier 4 Final emission standards in the United States and Canada using:

The 6015B meets Tier 4 Final emission standards in the United States and Canada using:- Cat NOx Reduction System captures and cools a small quantity of exhaust gas, then routes it into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

- Diesel Oxidation Catalyst (DOC) – uses a chemical process called oxidation to condition exhaust gases to meet emission standards.

- MEUI™-C Fuel System delivers increased fuel efficiency, while further reducing NOx emissions.

Sustainability

Meeting the needs of today without compromising the needs of tomorrow is the goal for all Cat machinery. The commitment to helping you operate safely and sustainably is affirmed in the design of the 6015B hydraulic mining shovel.

![]() The 6015B offers a number of sustainable benefits:

The 6015B offers a number of sustainable benefits:

![]() The 6015B is available with a C27 engine that meets Tier 4 Final emission standards for reduced emissions for the North American market.

The 6015B is available with a C27 engine that meets Tier 4 Final emission standards for reduced emissions for the North American market.

![]() Isochronous governing used on the 6015B engine keeps the engine running at the ideal speed in all load applications. This means less fuel burned. Great for the environment, and the bottom line.

Isochronous governing used on the 6015B engine keeps the engine running at the ideal speed in all load applications. This means less fuel burned. Great for the environment, and the bottom line.

![]() Automatic Engine Speed Control lowers engine RPM when the machine has not been working for a period of time, reducing engine noise and emissions, as well as preserving fuel.

Automatic Engine Speed Control lowers engine RPM when the machine has not been working for a period of time, reducing engine noise and emissions, as well as preserving fuel.

![]() Reduced operator and spectator sound levels result in less impact on the communities where the 6015B operates.

Reduced operator and spectator sound levels result in less impact on the communities where the 6015B operates.

![]() The 6015B cab provides the operator with a quiet work environment.

The 6015B cab provides the operator with a quiet work environment.

![]() Decrease your energy use and material consumption with a machine design that facilitates rebuilding.

Decrease your energy use and material consumption with a machine design that facilitates rebuilding.

![]() Ground-level accessible service fluid fill points ensure fast, easy, and secure replenishment of machine fluids.

Ground-level accessible service fluid fill points ensure fast, easy, and secure replenishment of machine fluids.

![]()

Seamless Dealer Support

Receiving 6015B parts from your local Cat Dealer is streamlined through the optimized use of Cat components, integrated part numbers, and stocking of parts in local Caterpillar warehouses. Your 6015B will be supported 24 hours a day, 7 days a week, by a worldwide network of parts distribution facilities, dealer service centers, and technical training facilities to keep it up and running at peak performance levels.

![]() With the use of Cat components throughout, you can rest assured that your local Cat Dealer is your most knowledgeable and trusted single source for your 6015B service and maintenance needs. Cat Dealer expert technicians have the unique knowledge, experience, training, and tooling necessary to fully support your 6015B hydraulic shovel, no matter the need or where your site is located.

With the use of Cat components throughout, you can rest assured that your local Cat Dealer is your most knowledgeable and trusted single source for your 6015B service and maintenance needs. Cat Dealer expert technicians have the unique knowledge, experience, training, and tooling necessary to fully support your 6015B hydraulic shovel, no matter the need or where your site is located.

![]() Consistent with any piece of Cat equipment, the 6015B is designed and built to provide maximum productivity capability and operating economy throughout its working life. To help you meet these performance levels with your 6015B, Cat dealers offer a wide range of service plans that maximize uptime and return on your investment, including:

Consistent with any piece of Cat equipment, the 6015B is designed and built to provide maximum productivity capability and operating economy throughout its working life. To help you meet these performance levels with your 6015B, Cat dealers offer a wide range of service plans that maximize uptime and return on your investment, including:![]() And although the 6015B is designed for easy operation, your Cat dealer can arrange training programs to help your operators improve productivity, increase uptime, reduce operating costs, and enhance safety.

And although the 6015B is designed for easy operation, your Cat dealer can arrange training programs to help your operators improve productivity, increase uptime, reduce operating costs, and enhance safety.

![]() The vast majority of Cat dealers across the globe have supported our line of hydraulic shovels for over a decade, so they are uniquely equipped to optimize the performance of your 6015B with their unmatched Cat hydraulic shovel expertise. This expertise includes a deep understanding of how the 6015B is best applied and utilized in all types of applications, so they can take your site-specific factors into account to help lower your operating and maintenance costs.

The vast majority of Cat dealers across the globe have supported our line of hydraulic shovels for over a decade, so they are uniquely equipped to optimize the performance of your 6015B with their unmatched Cat hydraulic shovel expertise. This expertise includes a deep understanding of how the 6015B is best applied and utilized in all types of applications, so they can take your site-specific factors into account to help lower your operating and maintenance costs.

![]()

- Preventative maintenance programs.

- Diagnostic programs, such as scheduled oil sampling and technical analysis.

- Rebuild and reman options.

- Customer support agreements.

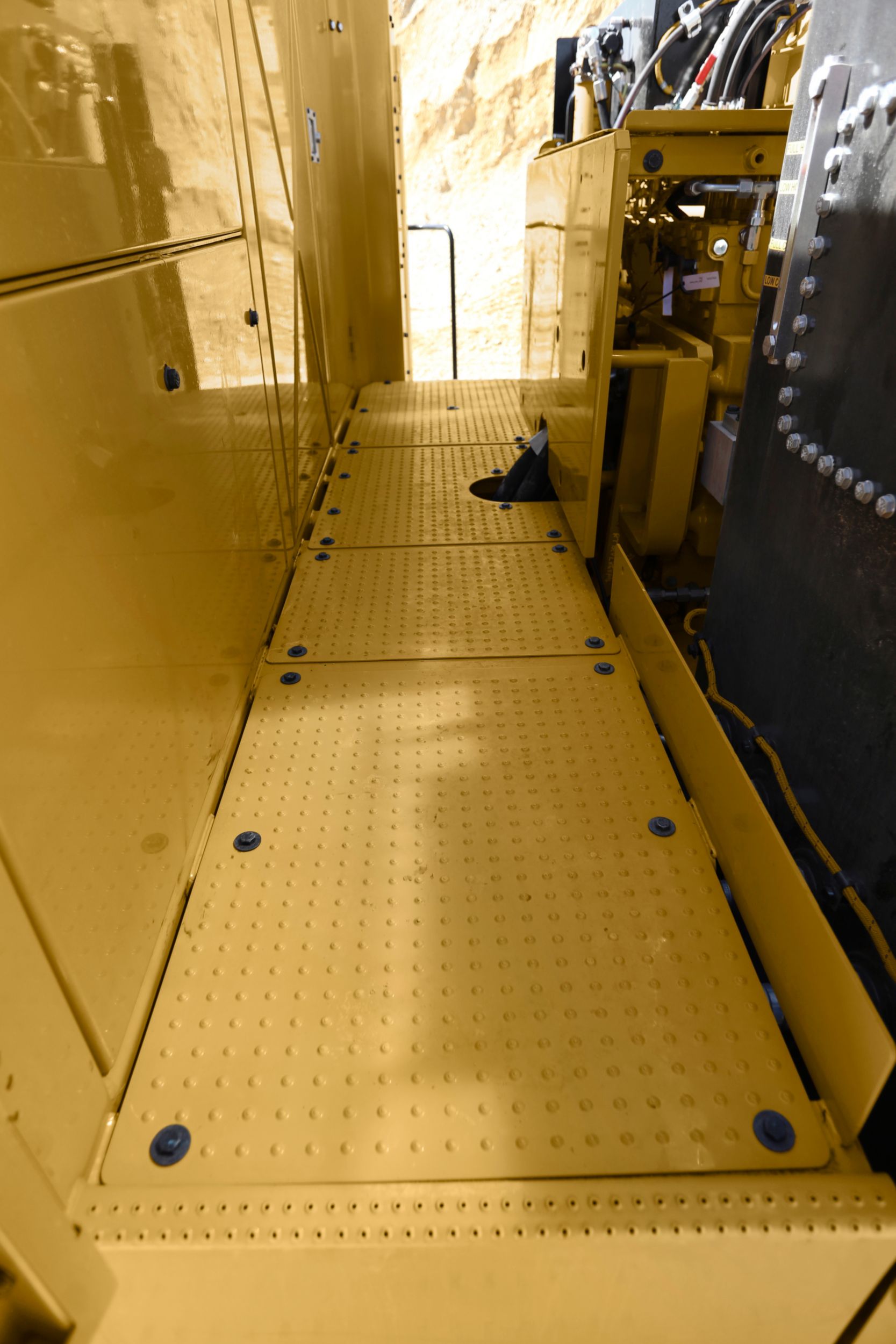

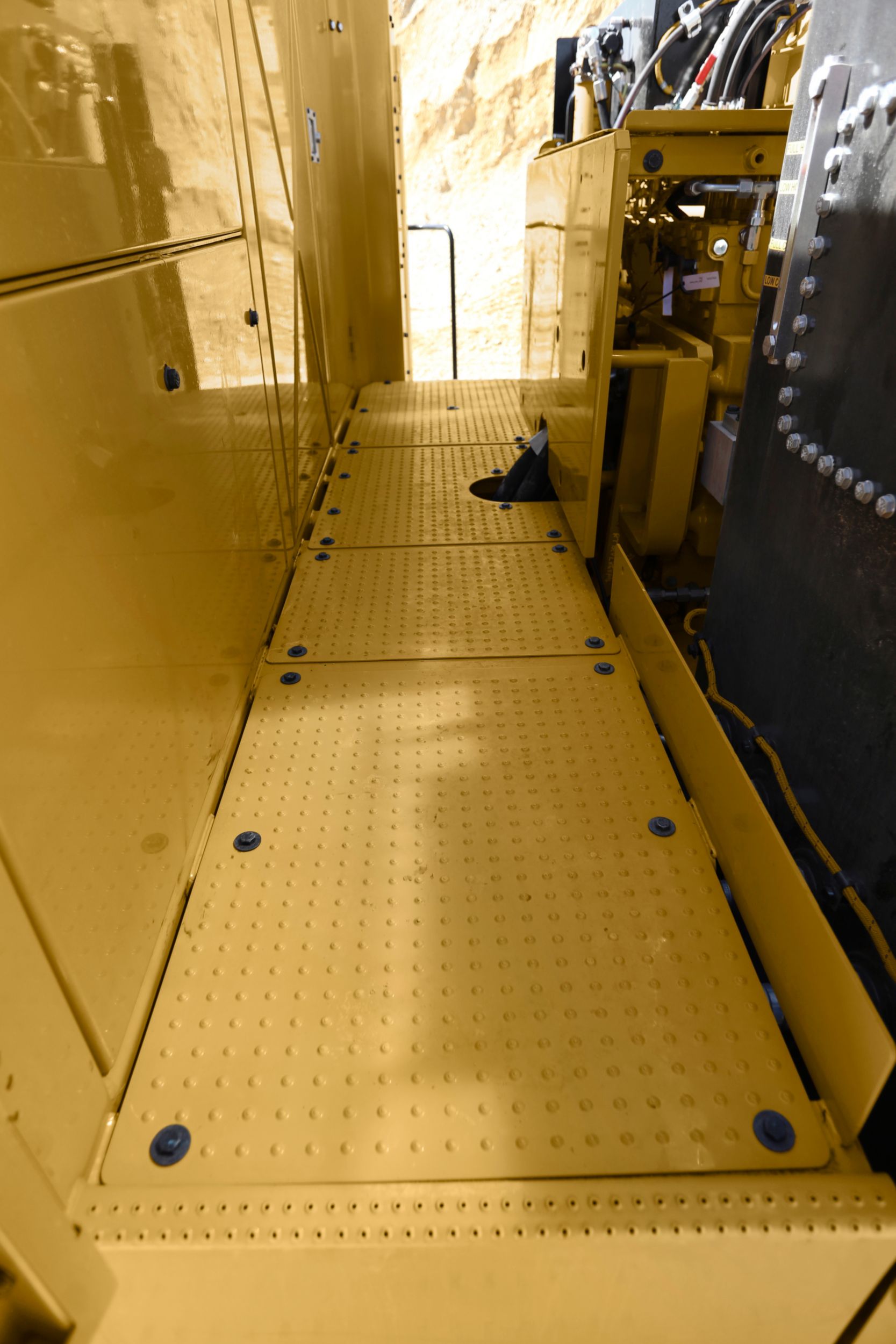

Serviceability

Designed for safe, easy serviceability and component accessibility, for greater uptime and increased productivity.

![]()

![]()

![]()

![]()

- Service locations are easily accessible from walkways or ground level, allowing critical, routine maintenance to get done quickly, safely and efficiently.

- Centralized lubrication points simplify servicing in to hard-to-reach locations.

- Stand-up engine compartment and pump room provide easy service access to engine and pumps.

- Right and left-hand service platforms with open grating provide access to cab, cross walkway, engine service doors and engine/pump room for safe, easy servicing.

- Access doors open outward for easy inspection.

- Large service doors provide ample room for inspection and servicing.

- Handrails enclose all walkways and service platforms for dependable service access.

- Fast fill fuel system at ground level and regular fill cap on top of tank.

- Spin-on filters for fuel and oil systems reduce changing time and help assure clean, tight seals.

- Lighted engine compartment and pump room.

- Optional ladder light, with ground level access switch, provides lighted entry and exit for maintenance personnel safety.

- Additional optional work lights provide excellent lighting to boarding, service and work areas in dark conditions.

- Fluid sight gauges for radiator, hydraulics, fuel and swing drives are visible from center of machine for daily fluid inspections.

- Scheduled Oil Sampling (S·O·SSM) ports for hydraulic system and engine oil provide a fast, convenient means of obtaining uncontaminated fluid samples for improved analysis and reliability.

- Key-On Fluid Level Check allows monitoring for fluid levels in the main cab display, prior to operation.

- Preventive maintenance program tracks time to next service interval and can optionally alert to upcoming interval due soon, or past due service.

- Hydraulic pressure test ports, at virtually every required location, provide quick, easy access for testing or adjusting hydraulic pressure.

- Standard autolube feature provides automatic lubrication at predetermined cycles for maintenance-free duty.

- Standard grease reel gun allows remote lubrication of front bucket linkage from ground level once per shift. No sensitive automatic lubrication lines on rear of bucket or linkage that are prone to damage.

- Modular design makes assembly, and disassembly for transport, quick and easy.

- Modular shipping enables quick, cost-effective hauling from site to site. – The superstructure can be transported as a single unit, with the engine ready to run. – Only requires assembly of the track roller frames, attachment (boom, stick and bucket), counterweight, and connection of the hydraulic hoses.

SPECIFICATIONS

- Engine Output - SAE J1995 606kW

- Bucket Payload 14.6t

- Operating Weight 140t

- Note Specifications shown above apply to Backhoe configuration. A Frontless configuration is also available.

- Engine Model Cat® C27

- Gross Power - SAE J1995 606kW

- Net Power - SAE J1349 556kW

- Number of Cylinders 12

- Bore 137.2mm

- Stroke 152.4mm

- Displacement 27l

- Maximum Altitude - Without Deration - Above Sea Level 3048m

- Engine Model Cat® C27

- Gross Power - SAE J1995 606kW

- Net Power - SAE J1349 556kW

- Number of Cylinders 12

- Bore 137.2mm

- Stroke 152.4mm

- Displacement 27l

- Aspiration Turbocharged and aftercooled

- Maximum Altitude - Without Deration - Above Sea Level 4420m

- Emissions U.S. EPA Tier 4 Final, Tier 2 Equivalent or Tier 1 Equivalent

- Operating Weight 140t

- Ground Pressure 16.3N/cm²

- Note Operating weight includes: 700 mm (28 in) track shoes, 7.6 m (24 ft 11 in) boom, 3.4 m (11 ft 2 in) stick

- Standard 700mm

- Wide 900mm

- Extra Wide 1000mm

- Number of Shoes - Each Side 46

- Number of Track Rollers - Each Side 9

- Number of Carrier Rollers - Each Side 3

- Track Pads Double grouser

- Travel Speed - Two Stages - 1st Stage - Maximum 2.3km/h

- Travel Speed - Two Stages - 2nd Stage - Maximum 3.3km/h

- Maximum Drawbar Pull - Forward 858kN

- Maximum Drawbar Pull - Reverse 983kN

- Gradeability - Travel Drives Approximately 42%

- Hydraulic Track Tensioning With accumulator

- Fuel Tank 1700l

- Cooling System 165l

- Engine Oil 87l

- Swing Drive 9l

- Hydraulic System - Including Tank 1752l

- Hydraulic Tank 956l

- Grease Tank 68l

- System Voltage 24V

- Batteries 4 × 200Ah (12V each)

- Alternator Rating 150A (24V)

- Components (1) Emergency stop in cabin, engine module, pump room and on service station accessible from ground level

- Components (2) All around lighting

- Components (4) Five (5) lights for front

- Components (9) One (1) beacon light on cabin roof

- Components (8) One (1) light for machine deck/service

- Components (6) One (1) light for right side

- Components (3) Four (4) lights on attachment

- Components (5) Two (2) lights for left side

- Components (7) Two (2) lights for rear end

- Main Pumps - Maximum Pressure - Travel 320bar

- Main Pumps - Maximum Pressure - Attachment 320bar

- Main Pumps - Maximum Total Oil Flow 1544L/min

- Main Pumps 3 × variable swash plate pumps

- Swing Pump - Maximum Flow - Swing 479L/min

- Swing Pump 1 × variable swash plate pump

- Swing Pump - Maximum Pressure - Swing 365bar

- Pilot Pump - Maximum Pressure, Pilot 95bar

- Pilot Pump 1 × gear pump

- Pilot Pump - Maximum Flow, Pilot 153L/min

- Engine Fan Pump - Maximum Pressure, Engine Fan 220bar

- Engine Fan Pump 1 × variable swash plate pump

- Engine Fan Pump - Maximum Flow, Engine Fan 201L/min

- Hydraulic Fan Pump - Maximum Flow, Hydraulic Fan 86L/min

- Hydraulic Fan Pump 1 × variable swash plate pump

- Hydraulic Fan Pump - Maximum Pressure, Hydraulic Fan 135bar

- Hydraulic Oil Cooling - Diameter of Fan 1016mm

- Hydraulic Oil Cooling - Maximum Flow 1075L/min

- Filters (1) Full-flow high-pressure filters (200 μm) for main pumps

- Filters (2) Full-flow filters (20 μm) for complete return circuit

- Filters (3) Pressure filters (16 μm) for servo circuit

- Filters (5) Swing charge filter (15 μm)

- Filters (6) Pump case return screens (125 μm)

- Filters (4) Full-flow filters (6 μm) for engine cooling return circuit

- Swing Drive Two (2) compact planetary transmissions with axial piston motors

- Parking Brake Wet multiple disc brake, spring-loaded/hydraulically released

- Maximum Swing Speed 4.9r/min

- Swing Ring Cross roller bearing with sealed internal gearing

- Features (1) Closed-loop swing circuit with speed control

- Features (2) Hydraulic braking of swing motion when control is returned to neutral position or by counteracting control for stronger braking

- Features (3) All raceways and the internal gearing of swing ring supplied by automatic central lubrication system

- Feature Accessible from ground level

- Equipped With (1) Emergency stop

- Equipped With (2) Quick couplings for: – Diesel fuel – Grease

- Travel Speed - Two Stages - 1st Stage - Maximum 2.3km/h

- Travel Speed - Two Stages - 2nd Stage - Maximum 3.3km/h

- Maximum Drawbar Pull - Forward 858kN

- Maximum Drawbar Pull - Reverse 983kN

- Gradeability - Travel Drives Approximately 42%

- Hydraulic Track Tensioning With accumulator

- Number of Shoes - Each Side 46

- Number of Track Rollers - Each Side 9

- Number of Carrier Rollers - Each Side 3

- Components (2) Chain links connected by hardened pins and bushings

- Components (5) Fully hydraulic self-adjusting track tensioning system with accumulator

- Components (7) Audible travel alarm

- Components (3) Cat D11 Track-Type Tractor links

- Components (6) Automatic hydraulic retarder valve to prevent overspeed on downhill travel

- Components (1) Forged double-grouser track pads

- Components (4) All running surfaces of sprockets, idlers, rollers and track chain links hardened

- Components (7) Beverage holder

- Components (4) Glass-breaking safety hammer

- Components (19) Laminated glass front upper window and tempered other windows

- Components (14) Adjustable armrest

- Components (9) AM/FM radio

- Components (17) Travel control pedals with removable hand levers

- Components (15) Height-adjustable joystick consoles

- Components (10) Radio with MP3 auxiliary audio port

- Components (16) Neutral lever (lock out) for all controls

- Components (1) Pressurized operator station with positive filtration

- Components (2) Mirror package

- Components (11) Two stereo speakers

- Components (12) Storage shelf suitable for lunch or toolbox

- Components (8) Literature holder

- Components (18) Two power outlets, 10 amp (total)

- Components (6) Coat hook

- Components (5) Removable lower windshield with in cab storage bracket

- Components (13) Color LCD display with warning, filter/fluid change, and working hour information

- Components (3) Sliding upper door window (left-hand cab door)

- Capacity - Grease Barrel 68l

- Type (2) Grease is automatically applied to all attachment pivot points (except bucket linkage) and slew bearing

- Type (3) Standard grease reel on machine for bucket linkage

- Type (1) Central bank lubrication system

- Type (4) Grease refill service point accessible from ground

- Type (1) Boom and stick torsion-resistant with welded box design

- Type (2) High-tensile steel with solid steel castings at pivot areas

- Type (3) Boom and stick stress-relieved after welding

- Type (4) Float valve for boom down function

- Buckets Equipped With – Special liner material covering main wear areas inside and outside – Lip shrouds – Wing shrouds – Heel shrouds

- Maximum Digging Depth 7.9m

- Maximum Digging Reach 13.9m

- Maximum Digging Height 13.2m

- Maximum Dump Height 8.7m

- Bucket Digging Force - SAE 501kN

- Stick Digging Force - SAE 439kN

- Bucket Digging Force - ISO 586kN

- Stick Digging Force - ISO 458kN

- Tooth System Cat C70 penetration tip with CapSure lock

- Capacity 1:1 8.1m³

- Total Width 2682mm

- Number of Teeth 5

- Weight - Including Standard Wear Package 7528kg

- Maximum Material Density - Loose 1.8t/m³

- Operating Weight 140,000kg

- Bucket Payload 14.6t

- Standard Bucket Capacity - Backhoe (Heaped 1:1) 8.1m³

- Gross Power - SAE J1995:2014 606kW

- Operating Weight 140t

- Net Power - SAE J1349 556 kW (746 hp 1,800 min-1)

- Net Power - SAE J1349 556 kW (746 hp 1,800 min-1)

- Gross Power - SAE J1995 606 kW (813 hp 1,800 min-1)

- Net Power - SAE J1349:2011 556kW

- Gross Power - SAE J1995 606 kW (813 hp 1,800 min-1)

- Engine Model Cat® C27

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS