US

METRIC

AP655F Steel Track

KEY SPECS

- Operating Weight - SE60 V Screed only 3400kg

- Standard Paving Range - SE60 V, SE60 V XW, SE60 VT XW 3.0-6.0 m (9' 10" - 19' 6")

- Maximum Paving Speed - With Tamper Bar Screed 25m/min

OVERVIEW

FEATURES AT A GLANCE

Fuel Efficient and Quiet

The C7.1 engine provides 151 kW (205 hp) and meets emission standards equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

Eco-mode utilizes an engine speed of 1650 rpm, reduces fuel burn and lowers sound levels. The machine is designed to operate in Eco-mode for most applications.

Eco-mode utilizes an engine speed of 1650 rpm, reduces fuel burn and lowers sound levels. The machine is designed to operate in Eco-mode for most applications.

![]() When automatic engine speed control is activated, the engine speed is reduced to an idle speed of 1000 rpm when the propel lever is moved to neutral or to 1300 rpm when screed heat is active.

When automatic engine speed control is activated, the engine speed is reduced to an idle speed of 1000 rpm when the propel lever is moved to neutral or to 1300 rpm when screed heat is active.

![]() Eco-mode and automatic engine speed control when activated together modify the engine rpm based on load factors. When activated the engine will operate at 1650 rpm when paving. If the upper power threshold is exceeded, the engine speed will increase to 2200 rpm and remain there until the demand drops below the threshold and remains there for 30 seconds, ensuring reliable performance.

Eco-mode and automatic engine speed control when activated together modify the engine rpm based on load factors. When activated the engine will operate at 1650 rpm when paving. If the upper power threshold is exceeded, the engine speed will increase to 2200 rpm and remain there until the demand drops below the threshold and remains there for 30 seconds, ensuring reliable performance.

![]()

Eco-mode utilizes an engine speed of 1650 rpm, reduces fuel burn and lowers sound levels. The machine is designed to operate in Eco-mode for most applications.

Eco-mode utilizes an engine speed of 1650 rpm, reduces fuel burn and lowers sound levels. The machine is designed to operate in Eco-mode for most applications.

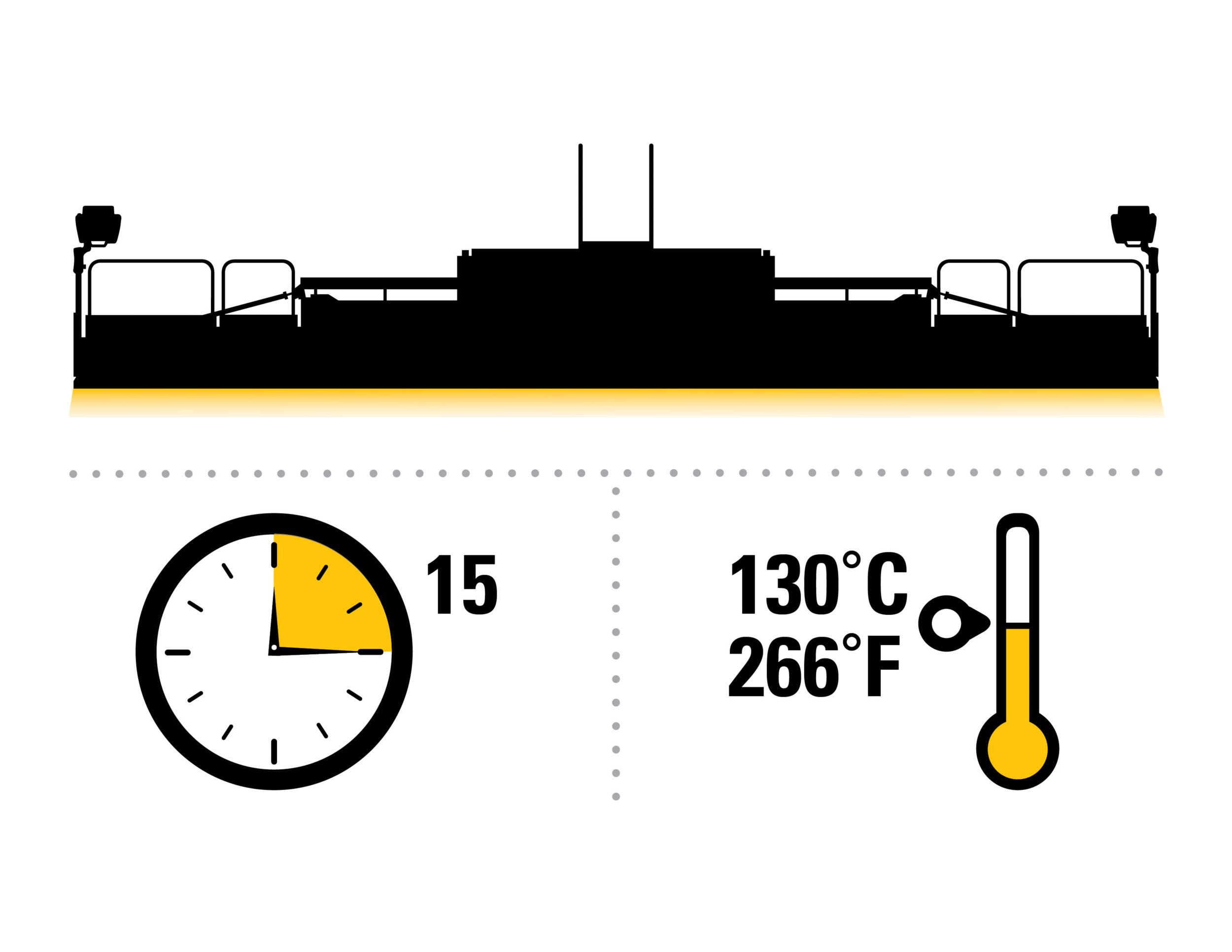

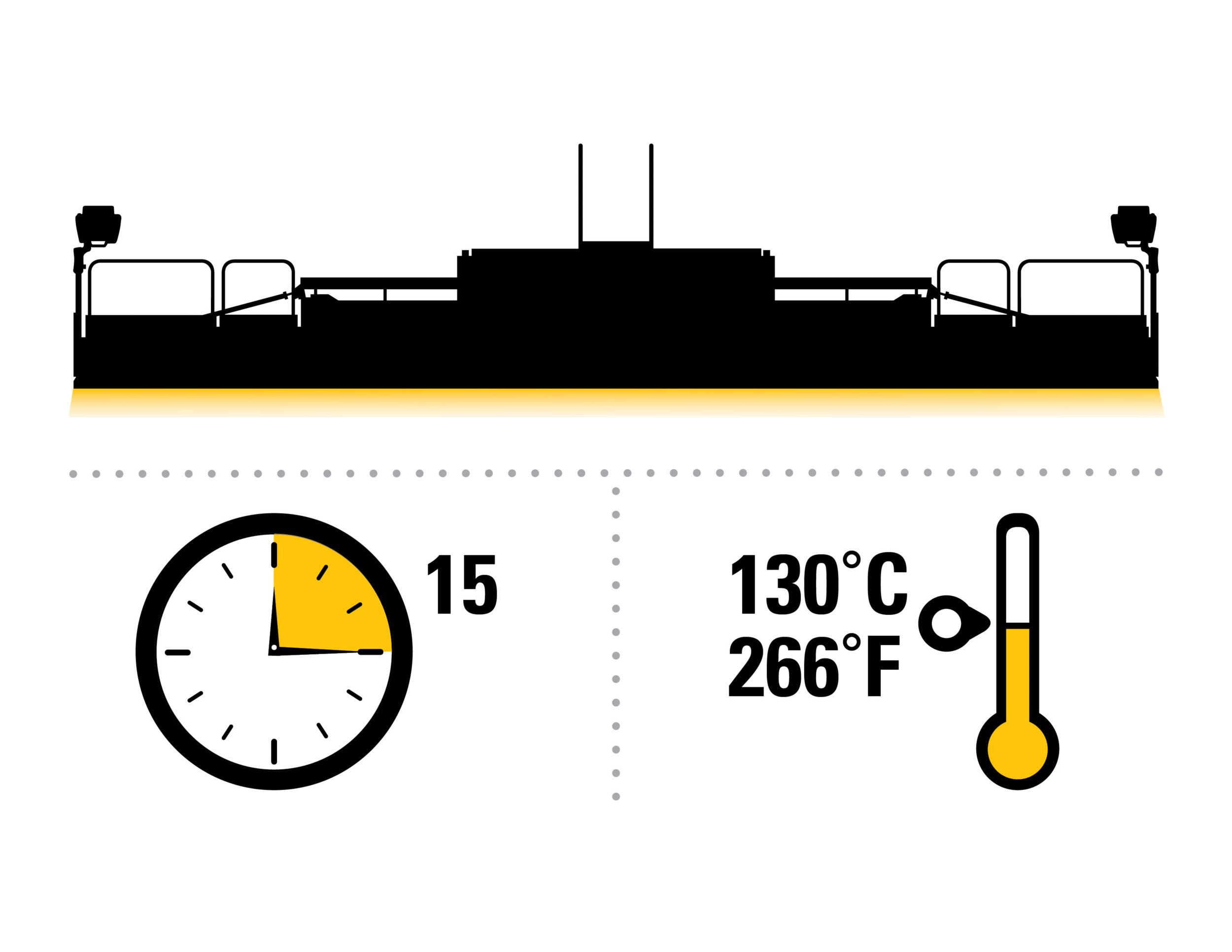

Quick Starter

Quiet heat operates at an engine speed of 1300 rpm and provides heating in under 15 minutes.

Quick heating mode provides a heat-up time in under 35 minutes when equipped with the wide-width paving package. Quick heat does not heat any faster than quiet heat when the screed is at standard extendable widths.

Quick heating mode provides a heat-up time in under 35 minutes when equipped with the wide-width paving package. Quick heat does not heat any faster than quiet heat when the screed is at standard extendable widths.

![]() Three preset heating options provide a wide range of temperatures for various mix designs; Low is 110 degrees C or 230 degrees F, medium is 130 degrees C or 266 degrees F, high is 160 degrees C or 320 degrees F.

Three preset heating options provide a wide range of temperatures for various mix designs; Low is 110 degrees C or 230 degrees F, medium is 130 degrees C or 266 degrees F, high is 160 degrees C or 320 degrees F.

![]()

Quick heating mode provides a heat-up time in under 35 minutes when equipped with the wide-width paving package. Quick heat does not heat any faster than quiet heat when the screed is at standard extendable widths.

Quick heating mode provides a heat-up time in under 35 minutes when equipped with the wide-width paving package. Quick heat does not heat any faster than quiet heat when the screed is at standard extendable widths.

More Control

The dual independent operating stations can extend beyond the frame for good all-around visibility. The low profile, front-mounted cooling system improves forward viewing and the redesigned auger assembly optimizes visibility to material height in front of the screed. The heated seat option, multiple seat adjustments, and tilting consoles conform to the operator to provide day-long comfort. The top-mounted cooling system directs fumes, hot air, and fan noise away from the crew for a cooler and quieter working environment.

The exclusive ventilation system draws fumes from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

The exclusive ventilation system draws fumes from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

![]()

The exclusive ventilation system draws fumes from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

The exclusive ventilation system draws fumes from the conveyor tunnel as well as the auger chamber and redirects them away from the operator for a more comfortable working environment.

Water Resistant Displays

Technology helps operators perform. Intuitive symbols and large graphics simplify operation, while the interactive LCD display with touchscreen access to generator activation, screed temperature control, and mix height adjustment, improve efficiency.

Single touch features for the auto-fill feeder system, feeder system activation, and hopper control, allow operators to concentrate on other duties for improved efficiency.

Single touch features for the auto-fill feeder system, feeder system activation, and hopper control, allow operators to concentrate on other duties for improved efficiency.

![]()

Single touch features for the auto-fill feeder system, feeder system activation, and hopper control, allow operators to concentrate on other duties for improved efficiency.

Single touch features for the auto-fill feeder system, feeder system activation, and hopper control, allow operators to concentrate on other duties for improved efficiency.

More Efficient Delivery

The auto-fill feeder system simplifies starts by alternating the conveyors and augers until the mix height reaches the sensor set point, eliminating manual activation and constant monitoring.

The two augers and two conveyors can be activated automatically with a single button simplifying setup. Each auger and each conveyor can be operated independently when needed.

The two augers and two conveyors can be activated automatically with a single button simplifying setup. Each auger and each conveyor can be operated independently when needed.

![]() The hopper wings and hydraulic apron can be folded with a single touch and release. The system can be tailored to activate left or right wings, or the front hydraulic apron independently or together.

The hopper wings and hydraulic apron can be folded with a single touch and release. The system can be tailored to activate left or right wings, or the front hydraulic apron independently or together.

![]() This feature activates the augers, conveyors, and tamper-bar (if equipped) at a reduced speed, allowing the application of release agents to prevent material build-up.

This feature activates the augers, conveyors, and tamper-bar (if equipped) at a reduced speed, allowing the application of release agents to prevent material build-up.

![]() Mix height adjustment in front of the screed can be modified from the tractor LCD display for increased versatility when needed.

Mix height adjustment in front of the screed can be modified from the tractor LCD display for increased versatility when needed.

![]() The optional 457 mm (18") hydraulic mainframe extensions attach to the auger assembly and provide smooth material flow out to the extenders. They retract with the screed extensions when reducing paving widths.

The optional 457 mm (18") hydraulic mainframe extensions attach to the auger assembly and provide smooth material flow out to the extenders. They retract with the screed extensions when reducing paving widths.

![]() The feeder system can be tailored to automatically operate with 0, 2, or 4 feed sensors. When paving with 0 sensors due to a failure, simply set the feeder system to automatic and adjust the mix height setting, no need to cycle the manual switch as previous models required.

The feeder system can be tailored to automatically operate with 0, 2, or 4 feed sensors. When paving with 0 sensors due to a failure, simply set the feeder system to automatic and adjust the mix height setting, no need to cycle the manual switch as previous models required.

![]() Hardware-free bed plates simplify replacement and bottom side mounting hardware for the chain guards eliminates bolt wear and material build-up for easier replacement.

Hardware-free bed plates simplify replacement and bottom side mounting hardware for the chain guards eliminates bolt wear and material build-up for easier replacement.

![]()

The two augers and two conveyors can be activated automatically with a single button simplifying setup. Each auger and each conveyor can be operated independently when needed.

The two augers and two conveyors can be activated automatically with a single button simplifying setup. Each auger and each conveyor can be operated independently when needed.

Steel Track Undercarriage

The low maintenance design with oscillating bogies and large track pads provide excellent flotation and smooth travel.

The large 3048 by 356 mm footprint, self-tensioning tracks and bonded track pads offer excellent traction and durability.

The large 3048 by 356 mm footprint, self-tensioning tracks and bonded track pads offer excellent traction and durability.

![]()

The large 3048 by 356 mm footprint, self-tensioning tracks and bonded track pads offer excellent traction and durability.

The large 3048 by 356 mm footprint, self-tensioning tracks and bonded track pads offer excellent traction and durability.

SE-Series Screeds

Exclusive zone monitoring allows heating to continue in the event of a temperature sensor failure. The system also monitors heating elements for failure conditions, eliminating unnecessary replacement.

![]() Feeder system ratio adjustment capability from the screed provides versatility. Standard hydraulic adjustment for extender height, slope, and crown, allows for on-the-go adjustment at standard and maximum paving widths.

Feeder system ratio adjustment capability from the screed provides versatility. Standard hydraulic adjustment for extender height, slope, and crown, allows for on-the-go adjustment at standard and maximum paving widths.

![]() Exclusive two-speed proportional extender control provides slower speeds for precise control around obstacles and quick reaction when extending paving widths.

Exclusive two-speed proportional extender control provides slower speeds for precise control around obstacles and quick reaction when extending paving widths.

![]() The heating elements slide out for easy replacement, no need to remove the screed plates. Machined screed frames simplify plate replacement and leveling.

The heating elements slide out for easy replacement, no need to remove the screed plates. Machined screed frames simplify plate replacement and leveling.

![]() Tamper-bar equipped screeds increase density as it tucks material under the screed plates. Three stroke settings of 2, 4, and 7 mm provide versatility and has a variable tamper speed of 700 to 1800 rpm.

Tamper-bar equipped screeds increase density as it tucks material under the screed plates. Three stroke settings of 2, 4, and 7 mm provide versatility and has a variable tamper speed of 700 to 1800 rpm.

![]() Exclusive power controls simplify adjustment across the entire 10.0 m (33 ft) paving width for better mat texture and quality. An innovative design utilizes extender slope to attach wide-width paving packages, eliminating the need for additional lifting devices.

Exclusive power controls simplify adjustment across the entire 10.0 m (33 ft) paving width for better mat texture and quality. An innovative design utilizes extender slope to attach wide-width paving packages, eliminating the need for additional lifting devices.

![]()

Cat Grade Control

F-Series pavers allow Cat Grade Control to be operated from any of the two tractor or two screed consoles. Split screen mode can be setup to monitor each side of the screed allowing single person operation.

![]() More accurate control, maximizes mix utilization, saves money. True averaging with sonic sensors that utilize 5 transducers, 2 readings are discarded and 3 averaged. A 10-point Auto-Calibration eliminates over/under adjustment from a single calibration point. Cross-coupling, slope and elevation are maintained with height adjustments. The true 9 m (30 ft) sonic averaging beam modifies tow point movement by 1/3 of total grade deviation.

More accurate control, maximizes mix utilization, saves money. True averaging with sonic sensors that utilize 5 transducers, 2 readings are discarded and 3 averaged. A 10-point Auto-Calibration eliminates over/under adjustment from a single calibration point. Cross-coupling, slope and elevation are maintained with height adjustments. The true 9 m (30 ft) sonic averaging beam modifies tow point movement by 1/3 of total grade deviation.

![]() Water-resistant displays, factory installed components, and consistent routing deliver performance. Sealed components withstand heat, moisture, and vibration, while the built-in temperature sensors provide better reliability than bail-type sensors.

Water-resistant displays, factory installed components, and consistent routing deliver performance. Sealed components withstand heat, moisture, and vibration, while the built-in temperature sensors provide better reliability than bail-type sensors.

![]()

SPECIFICATIONS

- Operating Weight - SE60 V Screed only 3400kg

- Standard Paving Range - SE60 V, SE60 V XW, SE60 VT XW 3.0-6.0 m (9' 10" - 19' 6")

- Maximum Paving Speed - With Tamper Bar Screed 25m/min

- Maximum Paving Speed - With Vibratory Screed 64m/min

- Inside Turn Radius 0.5m

- Maximum Travel Speed 6.5km/h

- Gross Power 151kW

- Engine Model Cat C7.1

- Fuel Tank Capacity 278l

- Operating Weight - Paver Only 16043kg

- Operating Weight - SE60 VT XW Screed only 4490kg

- Shipping Weight - Paver Only 15757kg

- Maximum Paving Width - SE50 V 6.5m

- DEF Tank 19.1l

- Standard Paving Range - SE50 V, SE50 VT 2.55-5.0 m (8' 4" - 16' 4")

- Operating Weight - SE50 VT Screed only 3340kg

- Maximum Throughput Capacity 1300tonnes/hr

- Hopper Capacity 7.1m³

- Operating Weight - SE60 V XW Screed only 4070kg

- Maximum Paving Width - SE60 V 7.65m

- Maximum Paving Width - SE50 VT 8m

- Operating Weight - SE50 V Screed only 3284kg

- Maximum Paving Width - SE60 V XW, SE60 VT XW 10m

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS