US

METRIC

AD22

KEY SPECS

- Engine Model Cat® C11

- Engine Power - Tier 3 Engine - ISO 14396:2002 236kW

- Bore 130mm

OVERVIEW

BENEFITS

-

HIGH AND LOW

- The AD22 is performing at its full 22-tonne capabilities in both the high altitudes of Peru, and the deep mines of Zambia, Canada and Russia.

-

TIGHT SPACES

- All wheel drive and an articulate hitch enable this truck to maneuver in tight space with excellent stability.

-

FLEXIBILITY

- Four different body sizes each feature wide trays, and we offer an ejector option for low roof conditions.

FEATURES AT A GLANCE

Power Train

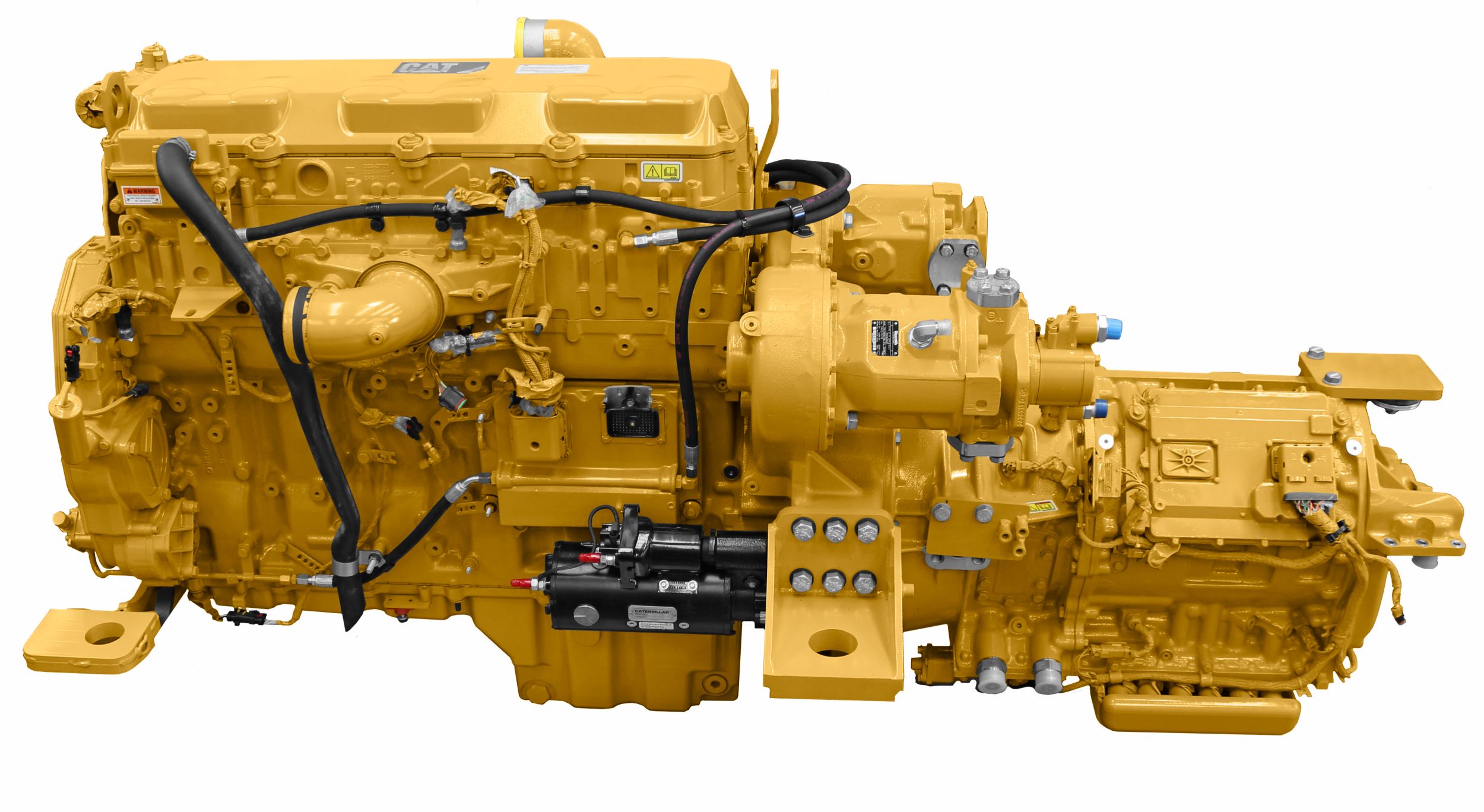

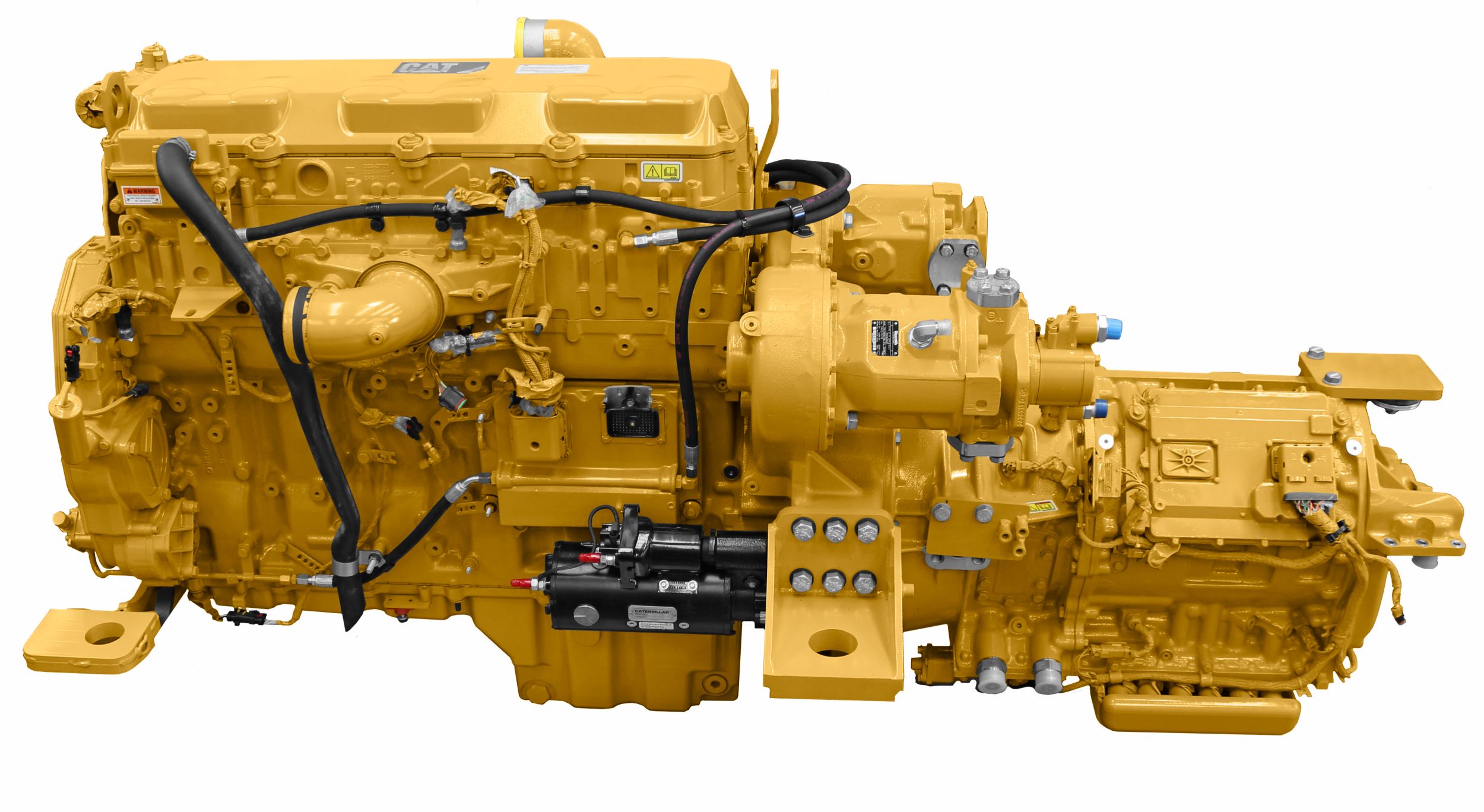

The Cat C11 ACERT diesel engine is a quiet, responsive performer that is proven in underground applications.

The C11 is an in-line, six-cylinder engine that uses ACERT to reduce emissions, deliver excellent fuel economy and provide outstanding low-end torque performance. The engine’s rated speed is 2,100 rpm.

Here are some quick statistics on this engine: ACERT is an emissions control and performance strategy developed by Caterpillar. It involves precise and efficient delivery of fuel using state of the art injectors, engine electronics and a proprietary method for routing air into the combustion process. The C11 ACERT uses MEUI – Mechanical Electronic Unit Injectors. One key to reducing emissions is to control temperature during combustion. To manage this, Caterpillar uses precisely timed microbursts of fuel during the four-stroke cycle. The quantity of fuel used will depend on the load being asked of the engine, and the fuel is highly atomized so that we’re using every drop for work.

ACERT is an emissions control and performance strategy developed by Caterpillar. It involves precise and efficient delivery of fuel using state of the art injectors, engine electronics and a proprietary method for routing air into the combustion process. The C11 ACERT uses MEUI – Mechanical Electronic Unit Injectors. One key to reducing emissions is to control temperature during combustion. To manage this, Caterpillar uses precisely timed microbursts of fuel during the four-stroke cycle. The quantity of fuel used will depend on the load being asked of the engine, and the fuel is highly atomized so that we’re using every drop for work.

![]() Coupled to the C11 ACERT is a Cat heavy-duty torque converter with an automatic Lock-Up Clutch and our planetary powershift transmission. These components are responsible for the nimble performance, speed on grade and all-wheel drive capabilities of the truck. The transmission features our Electronic Clutch Pressure Control (ECPC) technology. ECPC protects the transmission from pressure spikes that can reduce component life, and it produces a softer shift for operator comfort. Both the engine and transmission are equipped with Cat ADEM™ A4 electronic controls.

Coupled to the C11 ACERT is a Cat heavy-duty torque converter with an automatic Lock-Up Clutch and our planetary powershift transmission. These components are responsible for the nimble performance, speed on grade and all-wheel drive capabilities of the truck. The transmission features our Electronic Clutch Pressure Control (ECPC) technology. ECPC protects the transmission from pressure spikes that can reduce component life, and it produces a softer shift for operator comfort. Both the engine and transmission are equipped with Cat ADEM™ A4 electronic controls.

The torque converter and lock-up clutch manage available rimpull and drive train efficiency. If the truck is stopped on an uphill slope or under load conditions that require first gear – the truck will automatically select the gear it needs. This second gear take off is done automatically and is a component life and fuel saving feature.![]()

The C11 is an in-line, six-cylinder engine that uses ACERT to reduce emissions, deliver excellent fuel economy and provide outstanding low-end torque performance. The engine’s rated speed is 2,100 rpm.

Here are some quick statistics on this engine:

- The engine has a bore of 130 mm (5.2 in) and a stroke of 140 mm (5.51 in).

- In the AD22, it is turbocharged and aftercooled for performance.

- It has a displacement of 11.1 L (677.36 in³) and a compression ratio of 17.2:1.

ACERT is an emissions control and performance strategy developed by Caterpillar. It involves precise and efficient delivery of fuel using state of the art injectors, engine electronics and a proprietary method for routing air into the combustion process. The C11 ACERT uses MEUI – Mechanical Electronic Unit Injectors. One key to reducing emissions is to control temperature during combustion. To manage this, Caterpillar uses precisely timed microbursts of fuel during the four-stroke cycle. The quantity of fuel used will depend on the load being asked of the engine, and the fuel is highly atomized so that we’re using every drop for work.

ACERT is an emissions control and performance strategy developed by Caterpillar. It involves precise and efficient delivery of fuel using state of the art injectors, engine electronics and a proprietary method for routing air into the combustion process. The C11 ACERT uses MEUI – Mechanical Electronic Unit Injectors. One key to reducing emissions is to control temperature during combustion. To manage this, Caterpillar uses precisely timed microbursts of fuel during the four-stroke cycle. The quantity of fuel used will depend on the load being asked of the engine, and the fuel is highly atomized so that we’re using every drop for work.

The torque converter and lock-up clutch manage available rimpull and drive train efficiency. If the truck is stopped on an uphill slope or under load conditions that require first gear – the truck will automatically select the gear it needs. This second gear take off is done automatically and is a component life and fuel saving feature.

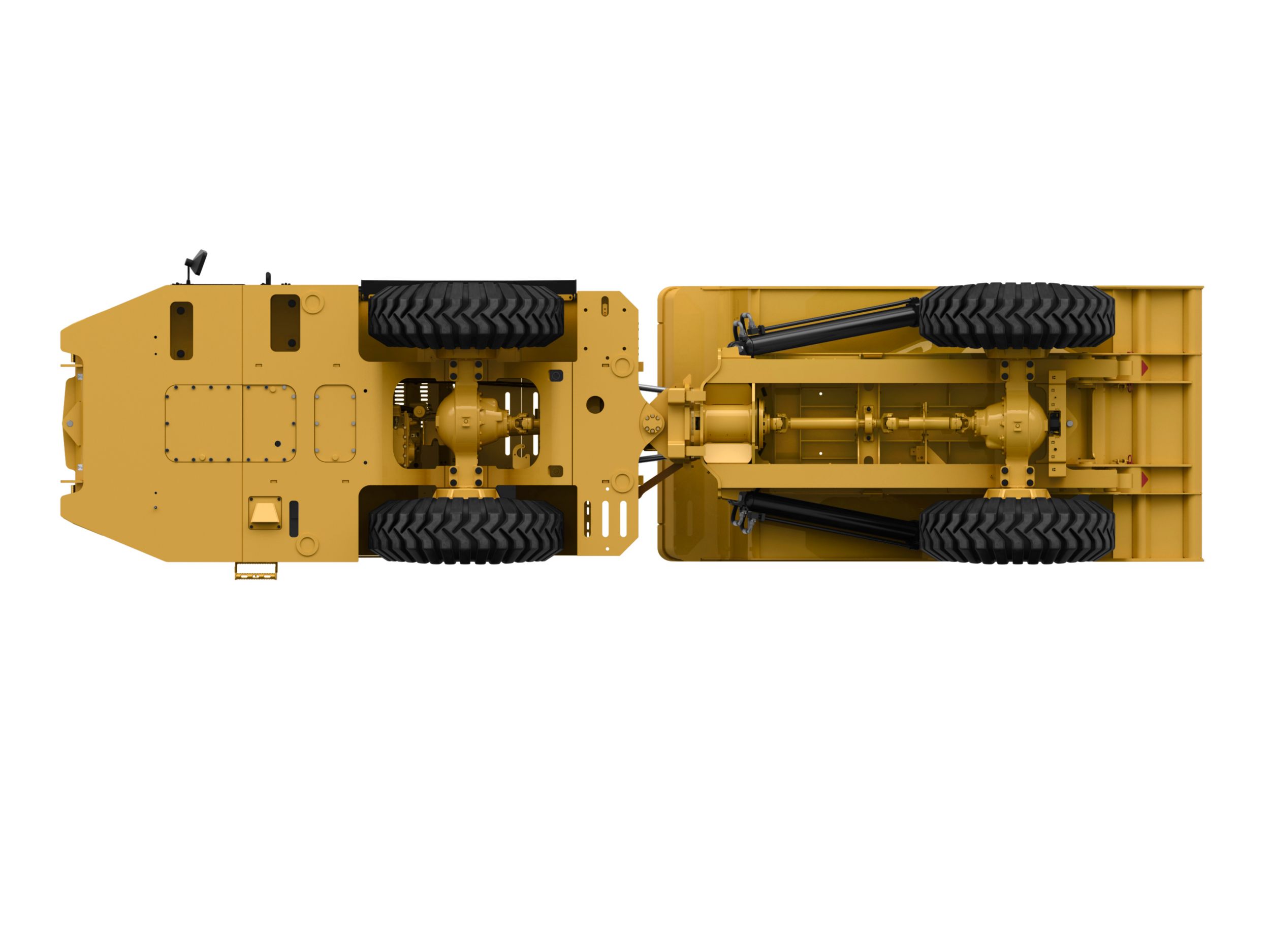

Machine Frame and Structures

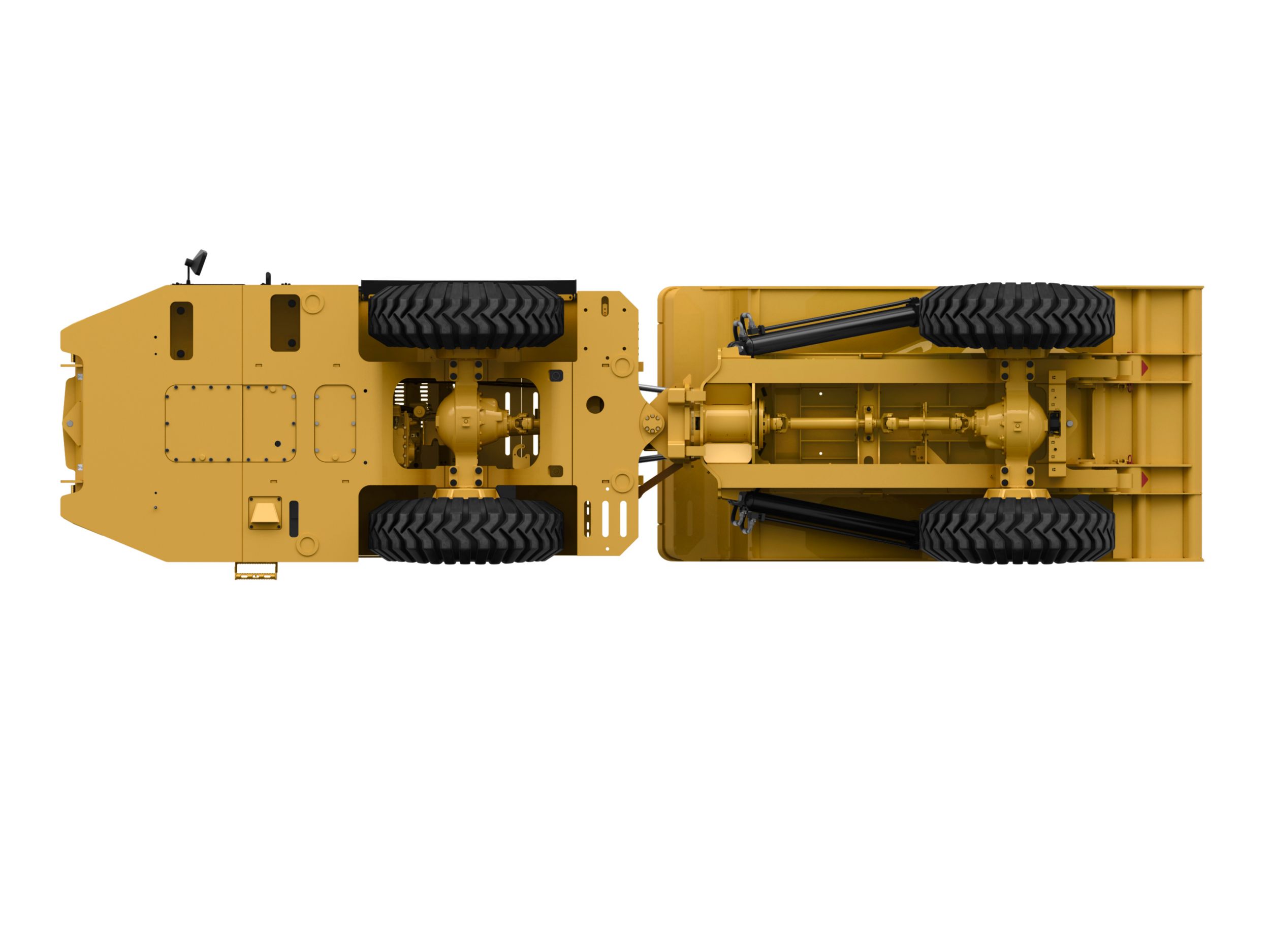

The AD22 frame is constructed using box sections and incorporates belly guards on the engine end frame. Used throughout Cat truck designs, our box section construction allows the frame to manage torque loads and impact stresses.

The AD22 has been designed to carry 48 percent of its loaded weight on the front axle and 52 percent on the rear – giving the truck excellent balance and a well-positioned center of gravity. These attributes contribute to the long term life of components, operator comfort and machine stability. Connecting the front and rear frames is an oscillating hitch that allows the two frames to work independently. The oscillating hitch has several advantages:

Connecting the front and rear frames is an oscillating hitch that allows the two frames to work independently. The oscillating hitch has several advantages: ![]() Braking is achieved at all four corners of the truck and includes manual retarding capability.

Braking is achieved at all four corners of the truck and includes manual retarding capability. ![]()

The AD22 has been designed to carry 48 percent of its loaded weight on the front axle and 52 percent on the rear – giving the truck excellent balance and a well-positioned center of gravity. These attributes contribute to the long term life of components, operator comfort and machine stability.

Connecting the front and rear frames is an oscillating hitch that allows the two frames to work independently. The oscillating hitch has several advantages:

Connecting the front and rear frames is an oscillating hitch that allows the two frames to work independently. The oscillating hitch has several advantages: - Allows all wheels to maintain contact with the ground in uneven haul road conditions.

- It allows the truck to maintain greater speed and control.

- One simple hydraulic system is used for braking, secondary braking, initiating the park brake (on all four wheels), and hydraulically retarding the truck.

- The hydraulic system for brake cooling uses a gear driven pump that continuously circulates oil through the system.

- The brakes feature multiple adjustment-free discs and plates that are force-cooled for predictable performance without brake fading.

Operator Station

The operator controls on the AD22 are both simple to learn, provide important machine information to the operator, and have ergonomically designed controls to help with operator comfort.

We offer two operator station options for the AD22 – enclosed and open. Both are ROPS/FOPS certified and isolation mounted to reduce vibration. Each also offers an excellent field of vision directly around the machine.

The enclosed cab has several key features centered around safety and comfort:

Both cab options can accommodate a variety of operator sizes with adjustable seat positioning and tilting steering column. Three points of contact are positioned to help get the operator in and out of the cab safely. Both cab configurations offer colored digital displays showing:

Both cab configurations offer colored digital displays showing: ![]()

We offer two operator station options for the AD22 – enclosed and open. Both are ROPS/FOPS certified and isolation mounted to reduce vibration. Each also offers an excellent field of vision directly around the machine.

The enclosed cab has several key features centered around safety and comfort:

- Sound suppression.

- Filtered air with air conditioning and heat.

- Mechanical suspension seating (Tee seat).

- Protective metal mesh for the rear window (optional).

Both cab options can accommodate a variety of operator sizes with adjustable seat positioning and tilting steering column. Three points of contact are positioned to help get the operator in and out of the cab safely.

Both cab configurations offer colored digital displays showing:

Both cab configurations offer colored digital displays showing: - Transmission selection.

- Current gear indicator.

- Engine coolant level.

- Engine temperature.

- Engine speed (RPM).

- Fuel level.

- Engine oil pressure.

- Truck speed.

Truck Body Options

Caterpillar is making available five body options for the AD22 to best match up with the specific gravity of your material.

Traditional Dump Bodies with a target payload of 22 tonnes (24 tons) include the following sizes: The single ejector body option is 9.7 m³ (12.7 yd³). This body option includes 8 mm (0.31 in) steel liner plate for abrasion resistance and additional wear material on rails. It includes a three stage ejector cylinder for quick unloading cycles. This body can be retrofitted to a traditional dump body chassis.

The single ejector body option is 9.7 m³ (12.7 yd³). This body option includes 8 mm (0.31 in) steel liner plate for abrasion resistance and additional wear material on rails. It includes a three stage ejector cylinder for quick unloading cycles. This body can be retrofitted to a traditional dump body chassis.

All bodies can be marked with optional reflective tape from the factory for improved visibility.

The AD22 is ideally pass matched with the R1300G and the R1600G/H – with three passes by the R1300G and two passes by the R1600G/H.![]()

Traditional Dump Bodies with a target payload of 22 tonnes (24 tons) include the following sizes:

- 9.0 m³ (11.8 yd³) (this body is standard to the machine).

- 10.0 m³ (13.1 yd³).

- 11.0 m³ (14.4 yd³).

- 12.0 m³ (15.7 yd³).

The single ejector body option is 9.7 m³ (12.7 yd³). This body option includes 8 mm (0.31 in) steel liner plate for abrasion resistance and additional wear material on rails. It includes a three stage ejector cylinder for quick unloading cycles. This body can be retrofitted to a traditional dump body chassis.

The single ejector body option is 9.7 m³ (12.7 yd³). This body option includes 8 mm (0.31 in) steel liner plate for abrasion resistance and additional wear material on rails. It includes a three stage ejector cylinder for quick unloading cycles. This body can be retrofitted to a traditional dump body chassis. All bodies can be marked with optional reflective tape from the factory for improved visibility.

The AD22 is ideally pass matched with the R1300G and the R1600G/H – with three passes by the R1300G and two passes by the R1600G/H.

Electrical and Hydraulic Systems – Simple Designs, Easily Serviced

One of the first things you notice as you look at the AD22 are the very clean hydraulic routings across the hitch.

The AD22 has three hydraulic systems:

All of the hydraulic systems are pulling from a single hydraulic tank that is bolted into the frame and has a refill capacity of 145 L (38.3 gal). A convenient access port simplifies cleaning the tank. Screens are located on the intakes to block debris.

Hydraulic oil filters have both manual and electronic sensors and will warn the operator if they become clogged.

The Cat cylinders used to steer as well as the body lift cylinders have a wiper mechanism to prevent any debris entering the cylinder.

The AD22 uses all hydraulic hosing for its routings – there are no tubes used in this truck. The AD22 electrical system is well designed around the corrosive environment typical of underground mining. Cat electrical connectors are designed for these environments, and our electrical harnesses have an excellent reputation for long life and wear in these challenging conditions. The integrity of our electrical components in this environment directly impact the reliability of the machine.

The AD22 electrical system is well designed around the corrosive environment typical of underground mining. Cat electrical connectors are designed for these environments, and our electrical harnesses have an excellent reputation for long life and wear in these challenging conditions. The integrity of our electrical components in this environment directly impact the reliability of the machine.

The AD22 is equipped with all LED lighting. The following are the standard lights available on the machine:![]()

The AD22 has three hydraulic systems:

- Gear pump driven brake cooling.

- Piston pump driven implement controls.

- Piston pump driven brake cooling.

All of the hydraulic systems are pulling from a single hydraulic tank that is bolted into the frame and has a refill capacity of 145 L (38.3 gal). A convenient access port simplifies cleaning the tank. Screens are located on the intakes to block debris.

Hydraulic oil filters have both manual and electronic sensors and will warn the operator if they become clogged.

The Cat cylinders used to steer as well as the body lift cylinders have a wiper mechanism to prevent any debris entering the cylinder.

The AD22 uses all hydraulic hosing for its routings – there are no tubes used in this truck.

The AD22 electrical system is well designed around the corrosive environment typical of underground mining. Cat electrical connectors are designed for these environments, and our electrical harnesses have an excellent reputation for long life and wear in these challenging conditions. The integrity of our electrical components in this environment directly impact the reliability of the machine.

The AD22 electrical system is well designed around the corrosive environment typical of underground mining. Cat electrical connectors are designed for these environments, and our electrical harnesses have an excellent reputation for long life and wear in these challenging conditions. The integrity of our electrical components in this environment directly impact the reliability of the machine. The AD22 is equipped with all LED lighting. The following are the standard lights available on the machine:

- Two dimming headlights.

- Brake and tail lights.

- Automatic reverse lighting.

- Cab mounted rear facing light.

Safety and Serviceability

One way this truck contributes to a safe work environment is its outstanding visibility to the work area. There is an excellent field of vision around the front of the truck, and rearview mirrors and a rear facing camera allow the operator to see what’s happening to the sides and to the back of their work space.

When operating in reverse, the truck will sound an alarm. Operating mostly in a very dark and visibility-challenged environment – we’ve made sure there’s good coverage by the LED lights on the machine, and visibility can be supplemented by optional high visibility tape placed on the truck.

The majority of all service and fluid level checks can be accomplished from ground level on this truck. The battery disconnect and engine lockout switches are located just behind the cab at ground level.

An engine shutdown switch is located near the engine and a second optional switch can be installed inside the cab.

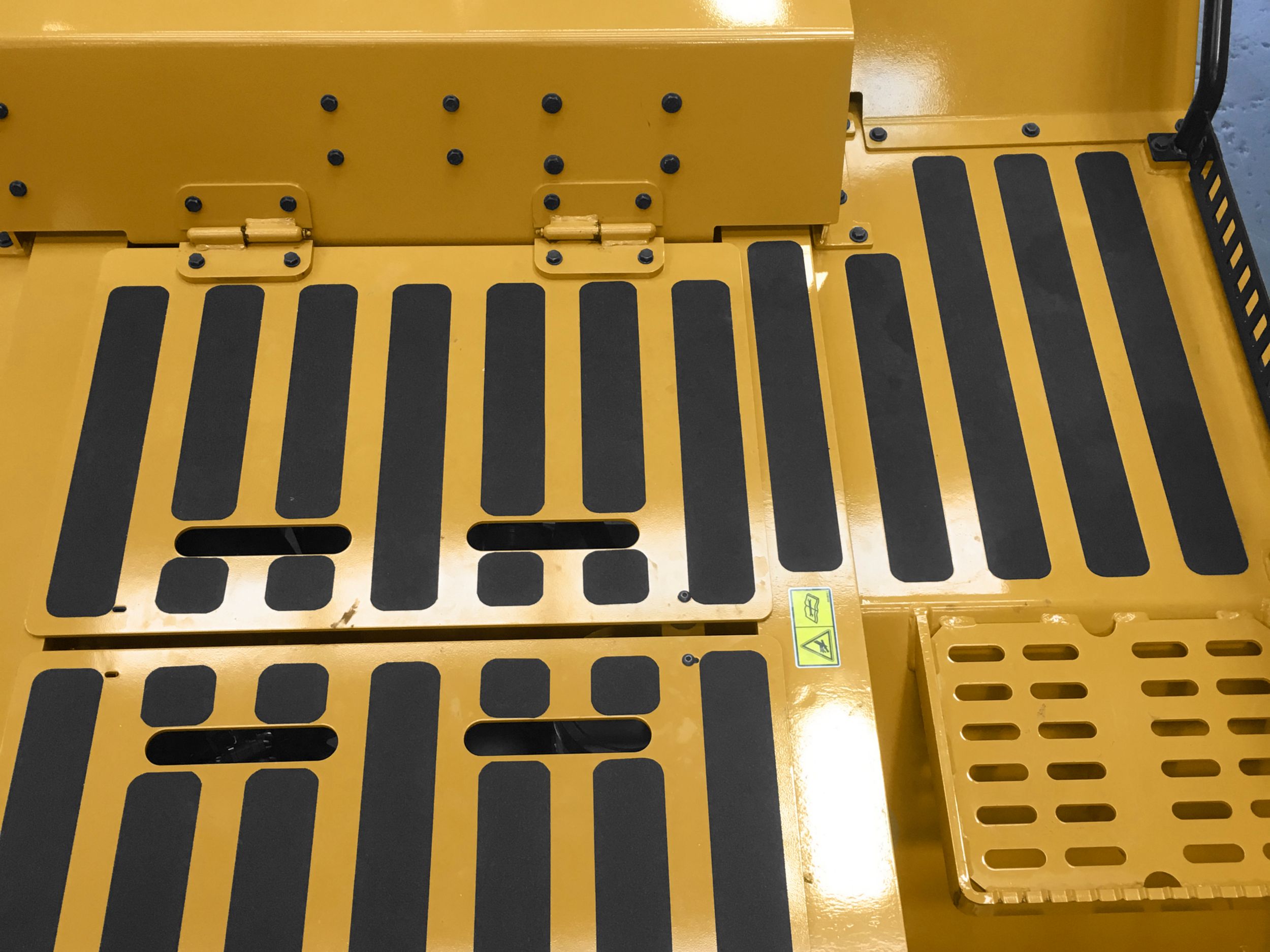

Service access ports located on top of the engine end frame are accessible under service covers that are easy to open and close.

All walk areas on top of the machine have anti-skid surfaces, and three points of contact using strategically placed handrails are possible when climbing up on the machine.

A steering frame lock is conveniently located on the machine, along with dump and ejector body retaining pins and we offer optional lift cylinders guards.

Any time you need parts, rebuild services or professionals who are the experts on your Cat equipment – reach out to your local Cat dealer.

When operating in reverse, the truck will sound an alarm. Operating mostly in a very dark and visibility-challenged environment – we’ve made sure there’s good coverage by the LED lights on the machine, and visibility can be supplemented by optional high visibility tape placed on the truck.

The majority of all service and fluid level checks can be accomplished from ground level on this truck. The battery disconnect and engine lockout switches are located just behind the cab at ground level.

An engine shutdown switch is located near the engine and a second optional switch can be installed inside the cab.

Service access ports located on top of the engine end frame are accessible under service covers that are easy to open and close.

All walk areas on top of the machine have anti-skid surfaces, and three points of contact using strategically placed handrails are possible when climbing up on the machine.

A steering frame lock is conveniently located on the machine, along with dump and ejector body retaining pins and we offer optional lift cylinders guards.

Any time you need parts, rebuild services or professionals who are the experts on your Cat equipment – reach out to your local Cat dealer.

SPECIFICATIONS

- Engine Model Cat® C11

- Engine Power - Tier 3 Engine - ISO 14396:2002 236kW

- Bore 130mm

- Stroke 140mm

- Displacement 11.15l

- Note (1) Power ratings apply at a rated speed of 2,100 rpm when tested under the reference conditions for the specified standard.

- Note (2) Ratings based on SAE J1995 standard air conditions of 25° C (77° F) and 100 kPa (29.61 Hg) barometer. Power based on fuel having API gravity of 35 at 16° C (60° F) and an LHV of 42 780 kJ/kg (18,390 BTU/lb) when engine used at 30° C (86° F).

- Note (3) Engine derate will commence at an altitude of 3353 m (11,000 ft).

- Nominal Payload Capacity 22000kg

- Gross Machine Mass 44220kg

- Body Capacities 9-12 m³ (11.8-15.7 yd³)

- Empty 21338kg

- Empty - Front Axle 16217kg

- Empty - Rear Axle 5121kg

- Loaded 44220kg

- Loaded - Front Axle 21204kg

- Loaded - Rear Axle 23016kg

- Empty - Front Axle 76.00%

- Empty - Rear Axle 24.00%

- Loaded - Front Axle 48.00%

- Loaded - Rear Axle 52.00%

- Forward - 1 5.6km/h

- Forward - 2 10.7km/h

- Forward - 3 16km/h

- Forward - 4 25.3km/h

- Reverse - 1 5.7km/h

- Note Maximum travel speeds with standard 18.00 × R25 tires.

- Differential Ratio 5.429

- Final Drive Ratio 4.765

- Total Reduction Ratio 25.87

- Raise 13s

- Lower 14s

- Total Cycle Time 27s

- Body 1 - Standard Body 9.00m³

- Body 2 10m³

- Body 3 11m³

- Body 4 12m³

- Ejector Body 9.7m³

- Note Heaped SAE 2:1.

- Outside Clearance Radius 7469mm

- Inner Clearance Radius 4095mm

- Frame Oscillation ±10°

- Articulation Angle 45°

- Engine Crankcase - With Filter 27l

- Transmission 20l

- Hydraulic Tank 145l

- Cooling System 57l

- Front Differential and Final Drives 44l

- Rear Differential and Final Drives 44l

- Fuel Tank 360l

- Transfer Gear Box 4.7l

- Tire Size 18.00 × R25

- Standards ROPS/FOPS certified cab

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS