US

METRIC

990K

KEY SPECS

- Rated Payload - Loose Material (Standard) 22t

- Rated Payload - Loose Material (High Lift) 20t

- Rated Payload - Standard (Quarry Face) 15.9t

OVERVIEW

BENEFITS

-

UP TO 54% BETTER FUEL EFFICIENCY

- Move more material with less fuel using economy mode

-

UP TO 10% LOWER MAINTENANCE COST

- Make regular maintenance more convenient with grouped service points

-

UP TO 10% MORE PRODUCTIVITY

- Deliver more productivity in most truck loading applications while using performance series buckets with increased capacities

FEATURES AT A GLANCE

PROVEN RELIABILITY

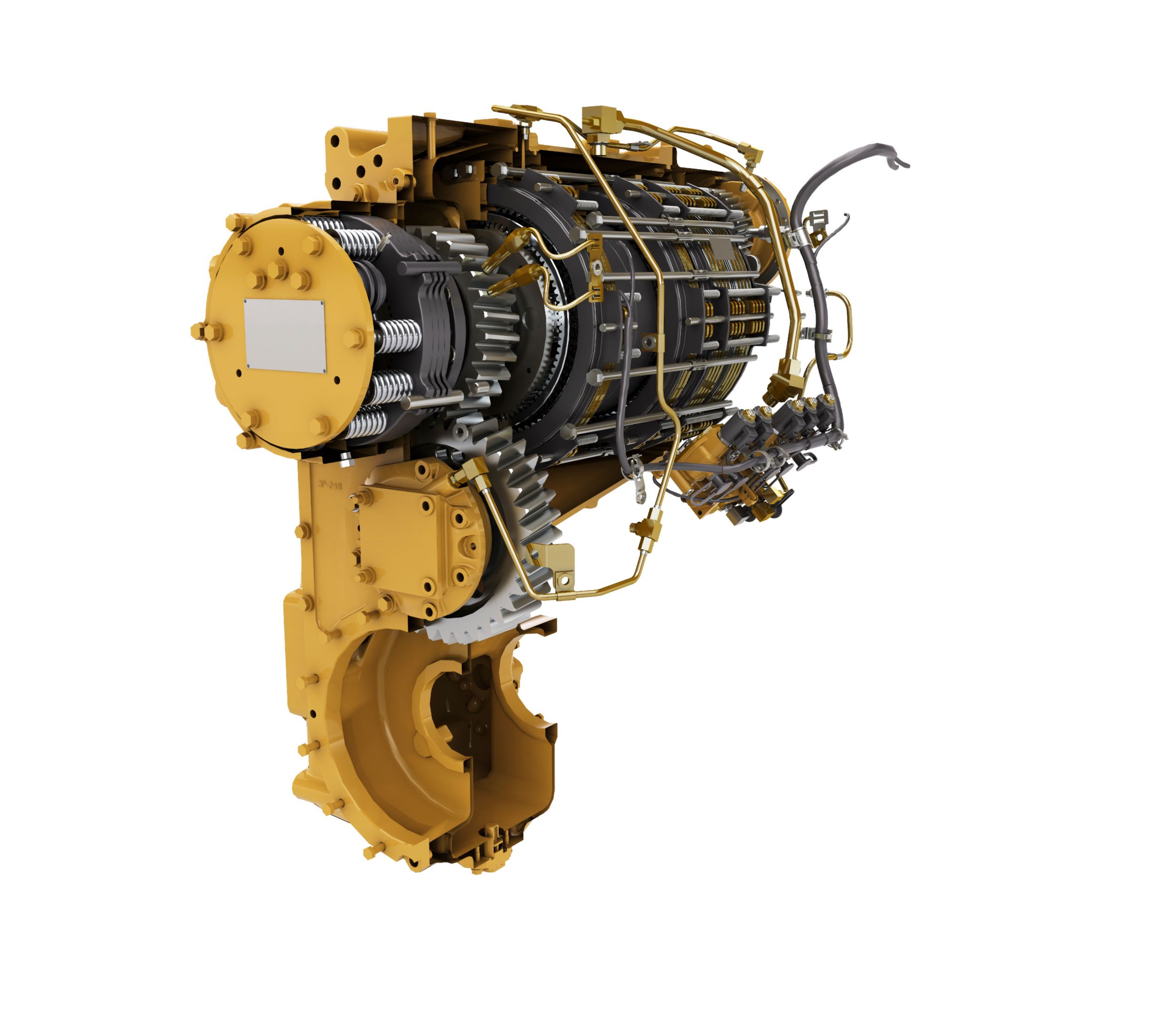

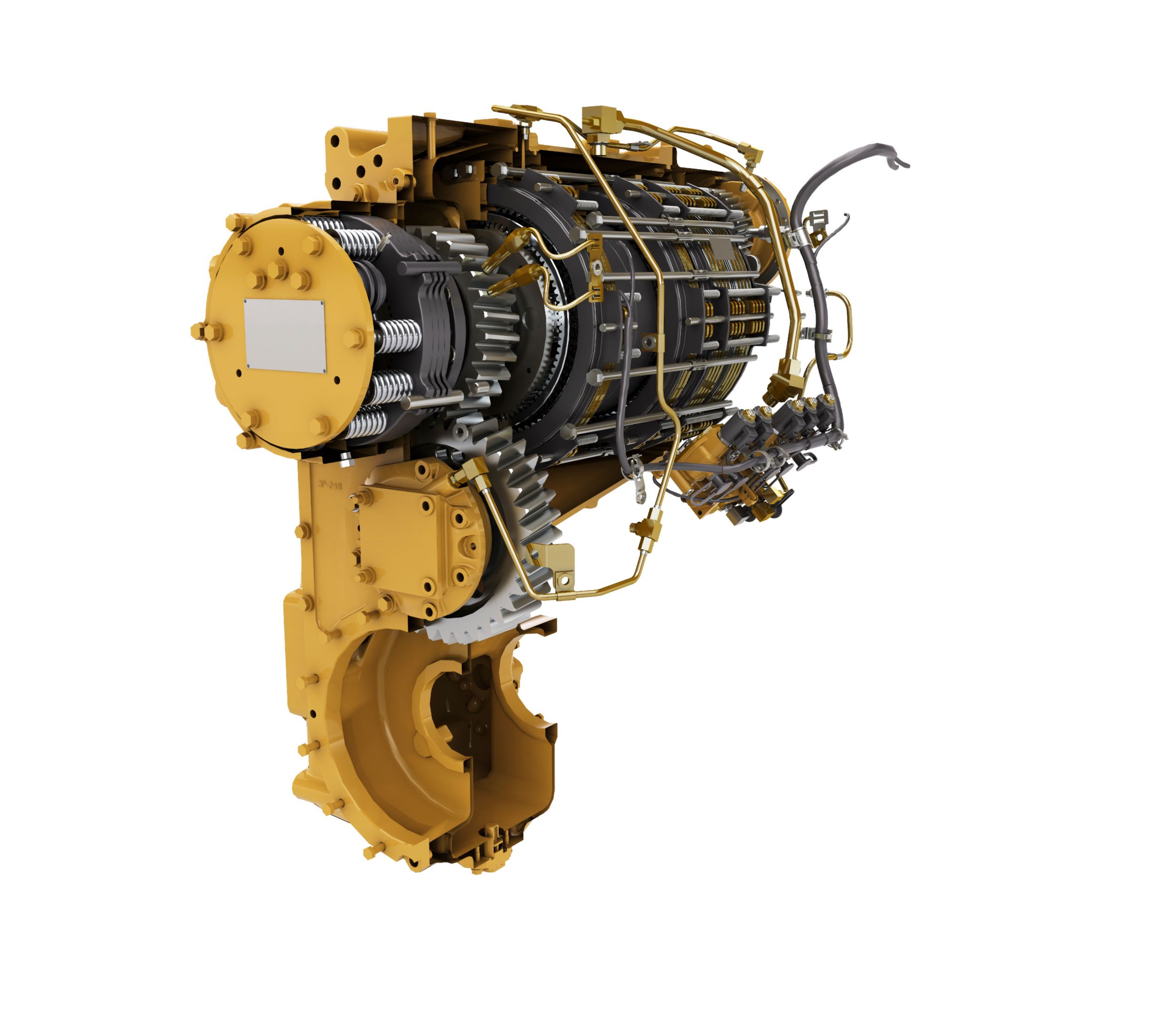

Experience maximum responsiveness and control with STIC that combines directional selection, gear selection and steering into a single lever. Building your success begins with a best-in-class transmission designed specifically for mining applications

Building your success begins with a best-in-class transmission designed specifically for mining applications![]() Durability and efficiency at the heart of your 990K comes from the Cat C27 Engine. Optimum performance is built in through the use of a 12 cylinder, direct injection design.

Durability and efficiency at the heart of your 990K comes from the Cat C27 Engine. Optimum performance is built in through the use of a 12 cylinder, direct injection design.![]() Lower your cost per ton utilizing advanced ICTC and RCS for modulated rimpull.

Lower your cost per ton utilizing advanced ICTC and RCS for modulated rimpull.![]()

- Simple side-to-side motion turns machine right or left, minimizing operator movements.

- Easy to operate finger controlled gear selection.

- Smoother, faster cycles and less operator fatigue through the use of low effort integrated controls.

Building your success begins with a best-in-class transmission designed specifically for mining applications

Building your success begins with a best-in-class transmission designed specifically for mining applications- Consistent, smooth shifting and efficiency through integrated electronic controls.

- Long life and reliability through heat treat gear and metallurgy.

- Three forward and three reverse speeds to match your application.

- Optimized performance and quick engine response with an electronic control module.

- Reliable efficiency with complete control over injection timing, duration and pressure with Mechanically Actuated Electronic Unit Injection (MEUI™).

- Extended engine life and improved fuel efficiency with reduced rated speed.

- Available in two versions: one that meets Tier 4 Final emission standards, and another that meets emission standards equivalent to Tier 2 emission standards.

- Reduce tire slippage and wear by modulating rimpull from 100 to 25 percent while depressing left pedal. After 25 percent rimpull is achieved the left pedal applies the brake.

- Reduce the potential for wheel slippage without reducing hydraulic efficiency with RCS.

- Improve fuel efficiency in certain applications with our lock-up clutch torque converter providing direct drive.

PERFORMANCE AND PRODUCTIVITY

Increase efficiency through our Positive Flow Control (PFC) Hydraulic System. PFC has concurrent pump and valve control. By optimizing pump control, hydraulic oil flow is proportionate to implement lever movement. Operators increase productivity with our responsive implements feature.

Operators increase productivity with our responsive implements feature.![]() Confident loader operation starts with precise machine control enabled by the 990K's load sensing hydraulic steering system.

Confident loader operation starts with precise machine control enabled by the 990K's load sensing hydraulic steering system.![]() Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.

Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.![]()

- Fast, productive cycles are enabled by the fully variable implement pump.

- Increase bucket feel and control through increased hydraulic response.

- Consistent performance and efficiency with lower system heat.

- Full hydraulic flow down to 1,600 engine rpm.

Operators increase productivity with our responsive implements feature.

Operators increase productivity with our responsive implements feature.- Operate comfortably through electronically controlled hydraulic cylinder stops.

- Handle easy-to-use soft detent controls.

- Conveniently set automatic implement kickouts from inside the cab.

- Increase efficiency with our variable displacement piston pumps.

- Achieve precise positioning for easy loading in tight areas with 35 degrees of steering articulation.

- Enhance operator comfort with integrated steering and transmission control functions.

- Case drain screens.

- Hydraulic oil cooler return filter.

- Pilot filter.

- Return screens inside hydraulic tank.

- Axle oil cooler screens if equipped.

OPERATOR COMFORT AND CONTROL

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.![]() Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.

Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.![]() Ergonomic placement of switches and Information display keep your operators comfortable all day every day.

Ergonomic placement of switches and Information display keep your operators comfortable all day every day.![]() Your operator's productivity is enhanced with our clean, comfortable cab environment.

Your operator's productivity is enhanced with our clean, comfortable cab environment.![]()

Enter and exit the cab easily and safely with these newly designed, ergonomic features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.- Fold up STIC steer/armrest.

- Reduced access stairway angles.

- Standard stairway lighting.

- Mid back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod and STIC steer that moves with the seat.

- 76 mm (3 in) wide retractable seat belt.

- Optional heated and ventilated seats.

- Large backlit membrane switches feature LED activation indicators.

- Switches feature ISO symbols for quick function identification.

- Two position rocker switch activates the electro hydraulic park brake.

- Experience reduced vibrations from isolation cab mounts and seat air suspension.

- Maintain desired cab temperature with automatic temperature controls.

- Pressurized cab with filtered air.

- Sound level reduced to a quiet 69 dB(A).

- Convenient floor storage tray/lunch box.

LONG TERM VALUE AND DURABILITY

Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest loading conditions.

![]() To ensure long life and reliability, the linkage pin joints feature a greased pin design with an auto lube system attachment available from the factory.

To ensure long life and reliability, the linkage pin joints feature a greased pin design with an auto lube system attachment available from the factory.

![]()

- Full box-section rear frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts efficiently transmit steering loads into the frame.

- Axle mounting has been optimized for increased structural integrity.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- High load stresses are absorbed by the solid steel lift arms.

- Enhance strength in key pin areas through the use of one piece castings.

- Stress relieved lift arms increase durability and lengthen time to repair.

POWERFUL EFFICIENCY

The Cat C27 engine is built and tested to meet your most demanding applications while meeting Tier 4 Final OR Tier 2 Equivalent emission standards. Maximize your uptime with the proven planetary power shift transmission. Improved shift quality, component life and operator comfort with our electronic transmission controls.

Maximize your uptime with the proven planetary power shift transmission. Improved shift quality, component life and operator comfort with our electronic transmission controls.

![]() Enable your operators to maximize efficiency by varying machine rimpull while putting more horsepower to hydraulics.

Enable your operators to maximize efficiency by varying machine rimpull while putting more horsepower to hydraulics.![]()

![]() Enabling maximum productivity and efficiency, all day every day.

Enabling maximum productivity and efficiency, all day every day.

The 990K systems work hard to save you fuel through advanced technologies. Utilizing On Demand Throttle, operators maintain normal operation with the left pedal and implements while the 990K manages the engine speed.![]()

- Fully integrated electronic engine controls works in concert with the entire machine to make your fuel go farther.

- Use less fuel idling with Engine Idle Shutdown.

- Maximized durability with Delayed Engine Shutdown.

Maximize your uptime with the proven planetary power shift transmission. Improved shift quality, component life and operator comfort with our electronic transmission controls.

Maximize your uptime with the proven planetary power shift transmission. Improved shift quality, component life and operator comfort with our electronic transmission controls.

- Reduced tire wear

- Enables full throttle shifts for faster cycle times

- Provides smooth approach to the dump target for less spillage and faster cycle times.

- Eliminates TC losses while lowering system heat

- Improves travel speeds

- Reduces cycle times in load and carry operations

The 990K systems work hard to save you fuel through advanced technologies. Utilizing On Demand Throttle, operators maintain normal operation with the left pedal and implements while the 990K manages the engine speed.

- Provides similar control and feel to our traditional throttle lock feature.

- Efficiency of manual throttle and the ergonomics of throttle lock.

PRODUCTIVITY WITH TECHNOLOGY

Integrated electronics provide flexible levels of information to both the site and the operator. This integration creates a smart machine and more informed operator, maximizing the productivity of both.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.![]() With the Product Link telematics system, you no longer have to rely on guesswork when managing your machine.

With the Product Link telematics system, you no longer have to rely on guesswork when managing your machine.![]() Connect directly to the machine and access a wide range of sensor information and advanced machine data.

Connect directly to the machine and access a wide range of sensor information and advanced machine data.![]()

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.

We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.- Intuitive operation and easy navigation with our enhanced user interface.

- Decrease service time by keeping operators informed about machine systems.

- Quick on-the-go weighing with the Cat Production Measurement.

- Access information through the easy-to-use VisionLink® website.

- Optimization of the machine availability through constant accessible information about machine systems and diagnostic codes.

- Track machine health with overviews of productivity, fuel consumption and payload.

- Up-to-date information on machine location, operating hours and geopolitical jurisdiction.

- Generate productivity reports with payload and duty cycle segmentation.

- Identify driver training needs based on productivity data.

- Detailed data logging of machine parameters and diagnostic codes.

- Monitor machine health by tracking machine sensor information with trend analysis and histograms.

SAVE ON SERVICE AND MAINTENANCE

We can help you succeed by ensuring your 990K has design features to reduce your downtime.

- Safe and convenient service with ground level or platform access and grouped service points.

- Swing-out doors on both sides of the engine compartment provide easy access to important daily service checks.

- Ecology drains for ease of service and prevention of spills.

- Reduce downtime with VIMS system notifications so your operators and technicians can resolve any problems before failure.

- Ground level access to transmission control valves.

TOP-TIER SERVICE AND SUPPORT

A valued partner, your Cat dealer is available whenever you need them.

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

SAFETY FIRST

We are constantly introducing features on our machines in an effort to enhance safety for the operators.

![]()

![]()

![]()

- Left and right hand stairs with 45 degree angle enhance safety for operators getting on and off the 990K.

- Continuous walkway with non-skid surfaces are designed into the service areas.

- Maintain three points of contact at all times through ground level or platform accessible service areas.

- Optional heated mirrors ensure enhanced visibility for safe operation.

- Standard Cat Vision or optional Cat Detect with radar increase operator awareness around the machine.

- Optional HID or LED lights provide excellent workspace visibility.

- Optional cab mounted LED warning beacons.

- Reduced vibrations to the operator with isolated cab mounts and seat mounted implement and steering controls.

- Low interior sound levels.

- Pressurized cab with filtered air.

- Conveniently train other operators in comfort with our standard training seat.

- Standard 76 mm (3 in) seat belts on the operator seat and the standard trainer seat.

REDUCE ENVIRONMENT IMPACT

Sustainability is designed and built into our 990K's features.

- Engine Idle Shutdown can help you save fuel by avoiding unnecessary idling.

- The 990K is built for multiple lives. To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

EFFICIENT EQUIPMENT MATCH

For full truck payloads with minimum loading time, an efficient loading/hauling system starts with a perfect match. Cat wheel loaders are matched with Cat off-highway trucks to maximize volume of material moved at the lowest operating cost per ton. The 990K equipped with the standard linkage will pass match the 773 (54 tonnes/60 tons) in 3 passes and the 775 (64 tonnes/70 tons) in 4 passes. Equipped with a high lift linkage the 990K is capable of loading a 777 (91 tonnes/100 tons) in 6 passes.

ATTACHMENTS TO MEET YOUR NEEDS

Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you.

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 990K buckets are manufactured with the Performance Series design.

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 990K buckets are manufactured with the Performance Series design.

![]() Designed for use in bank or face loading of limestone and other unprocessed rock. Application also includes truck and hopper loading for a wide range of quarry materials. GET includes spade nose cutting edge with adapters, half arrow segments, bottom wear plates, boxed wings and side bar protectors.

Designed for use in bank or face loading of limestone and other unprocessed rock. Application also includes truck and hopper loading for a wide range of quarry materials. GET includes spade nose cutting edge with adapters, half arrow segments, bottom wear plates, boxed wings and side bar protectors.

![]() Applications: Loading loose, stockpiled material.

Applications: Loading loose, stockpiled material.

![]() Multiple GET options are available to customize your 990K to your application, such as:

Multiple GET options are available to customize your 990K to your application, such as:![]()

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 990K buckets are manufactured with the Performance Series design.

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 990K buckets are manufactured with the Performance Series design.

- Sidebar protectors.

- General duty and penetration tips.

- Standard and half arrow segments.

PERFORMANCE WITH LESS FUEL

Data from customer machines show Cat wheel loaders are among the most fuel efficient machines in the industry.

Several features contribute to this excellent fuel efficiency:

Several features contribute to this excellent fuel efficiency:![]() Machine configuration, operator technique, and job site layout can impact fuel consumption.

Machine configuration, operator technique, and job site layout can impact fuel consumption.![]()

Several features contribute to this excellent fuel efficiency:

Several features contribute to this excellent fuel efficiency:- Performance Series Buckets – Deliver faster fill times and better material retention, ultimately reducing cycle times while improving productivity and fuel efficiency.

- Positive Flow Control Hydraulics – Provides only the hydraulic flow required by the implement systems for improved fuel efficiency and greater rimpull.

- Engine – Advanced engine controls maximizes power and efficiency.

- Economy Mode – Featuring On Demand Throttle, Economy Mode optimizes power for maximum fuel savings with minimal impact on production.

- Engine Idle Shutdown – Automatic engine and electrical system shutdown conserves fuel.

- Lock up Torque Converter – Transfers more power to the ground and optimizes fuel efficiency in all applications.

- Machine Configuration – Select the correct work tool and tire type based on machine application. Ensure proper inflation pressures. Utilize the Economy Mode setting for maximum efficiency.

- Job Site Layout – Spot loading targets in the right position. Avoid traveling more than 1.5 tire revolutions during truck loading cycles. Reduce transport distance for load and carry cycles by optimizing job site layout.

- Loading Bucket – Load in first gear. Raise and tilt bucket quickly and do not use a "pumping" motion. Avoid lift lever detent and use impeller clutch.

- Loading Truck or Hopper – Do not raise the work tool any higher than necessary. Keep engine rpm low and unload in controlled manner.

- Idle – Set the parking brake to engage Engine Idle Management System.

SPECIFICATIONS

- Rated Payload - Loose Material (Standard) 22t

- Rated Payload - Loose Material (High Lift) 20t

- Rated Payload - Standard (Quarry Face) 15.9t

- Rated Payload - High Lift (Quarry Face) 15.9t

- Bucket Capacity Range 8,6 m³ – 10,0 m³ (11,25 yd³ – 13,0 yd³)

- Cat Truck Match - Standard 773-775

- Cat Truck Match - High Lift 775-777

- Net Power 521kW

- Operating Weight 80974kg

- Bucket Capacities 7,4-14,9 m³ (9,7-19,5 yd³)

- Engine Model C27 Cat®

- Bore 137.2mm

- Stroke 152.4mm

- Displacement 27.03l

- Torque Rise 18%

- Rated Speed 1,800/min

- Transmission Type Cat-Planetenlastschaltgetriebe

- Forward - 1 7.3km/h

- Forward - 2 13.3km/h

- Forward - 3 22.9km/h

- Reverse - 1 7.9km/h

- Reverse - 2 14.7km/h

- Reverse - 3 24.9km/h

- Direct Drive - Forward 1 Lock-up disabled

- Direct Drive - Forward 2 13.7km/h

- Direct Drive - Forward 3 24.5km/h

- Direct Drive - Reverse 1 8.7km/h

- Direct Drive - Reverse 2 15.4km/h

- Direct Drive - Reverse 3 26.4km/h

- Front Fixed

- Rear Trunnion

- Oscillation Angle 8.5°

- Raise 8.2s

- Dump 2.9s

- Fuel Tank 1114l

- Cooling System 208l

- Transmission 110l

- Rated Speed - Net Power - SAE J1349 - Standard Ambient 521kW

- Pilot System Open loop and pressure reducing

- Operator Sound Level (ISO 6396:2008) 69dB(A)

- Machine Sound Level (ISO 6395:2008) 113dB(A)

- Rated Speed - Net Power - SAE J1349 - High Ambient 483kW

- Hydraulic Tank - Implement and Hydraulic Fan 261l

- Machine Sound Level (ISO 6395:2008) 115dB(A)

- Lower Float Down 3.6s

- Maximum Flow at 1,800 rpm (1) 817l/min

- Lower 3.7s

- Total Hydraulic Cycle Time - Empty Bucket 13.8s

- Rated Speed - Gross - SAE J1995 571kW

- Operator Sound Level (ISO 6396:2008) 69dB(A)

- Net Power - SAE J1349:2011 521kW

- Cylinders, Double Acting - Lift, Bore and Stroke 235 mm × 1287 mm (9.3 in × 50.7 in)

- Differential - Final Drives - Rear 261l

- Relief Valve Setting - Lift/Tilt 33000kPa

- Total Steering Angle 70°

- Steering System - Pump Piston, variable displacement

- Maximum Flow at 1,800 rpm (2) 84l/min

- Differential - Final Drives - Front 271l

- Relief Valve Setting - Main 3500kPa

- Emissions U.S. EPA Tier 4 Final OR Tier 2 Equivalent

- Note Travel speeds based on Michelin 45/65R39 LD D2**L5 tires.

- Rated Speed - Gross - ISO 14396 561kW

- Rack Back 4.3s

- Gross - ISO 14396 561kW

- Peak Torque - 1,200 rpm 3557N·m

- Steering System - Circuit Pilot, load sensing

- Steering ISO 5010: 2007

- Hydraulic Tank - Steering and Braking 132l

- Relief Valve Setting - Steering 32000kPa

- Engine Crankcase 75.7l

- Lift/Tilt System - Circuit Positive flow control

- Cylinders, Double Acting - Tilt, Bore and Stroke 292.1 mm × 820 mm (11.5 in × 32.3 in)

- Hydraulic System Factory Fill 795l

- ROPS/FOPS ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards

- Maximum Flow at 1,400 rpm 358l/min

- Lift/Tilt System Variable displacement piston

- Note All nonroad U.S. EPA Tier 4 diesel engines are required to use only Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less. Biodiesel blends up to B20 (20% blend by volume) are acceptable when blended with 15 ppm (mg/kg) sulfur or less ULSD. B20 should meet ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel spec, ASTM D6751 or EN 14214. Cat DEO‑ULS™ or oils that meet the Cat ECF-3, API CJ‑4, and ACEA E9 specification are required. For further fluid specifications and guidelines, visit: http://parts.cat.com/cda/files/3244668/7/SEBU6250-19.pdf.

- Brakes ISO 3450: 2011

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS