US

METRIC

986H

OVERVIEW

FEATURES AT A GLANCE

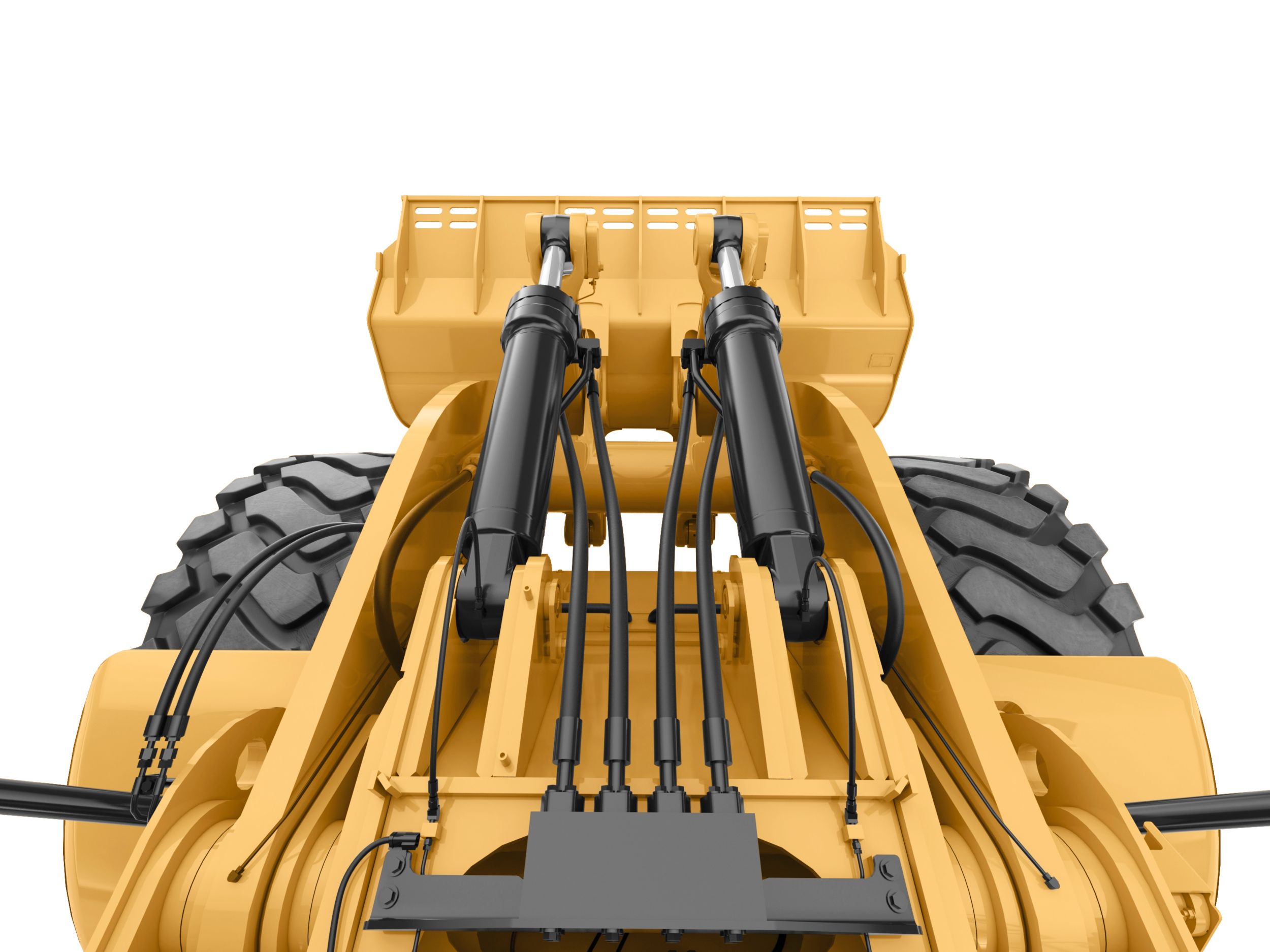

Structures

Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest loading conditions. ![]() Your key to maximum uptime and productivity is our field-proven lift arms.

Your key to maximum uptime and productivity is our field-proven lift arms.  To ensure long life and reliability, the linkage pin joints feature a greased pin design with optional auto lube system.

To ensure long life and reliability, the linkage pin joints feature a greased pin design with optional auto lube system.

- Full box-section rear frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts efficiently transmit loads into the frame.

- Cast axle pivot mounting areas better disperse stress loads for increased structural integrity.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- High load stresses are absorbed by the solid steel lift arms.

- Enhance strength in key pin areas through the use of one piece castings.

To ensure long life and reliability, the linkage pin joints feature a greased pin design with optional auto lube system.

To ensure long life and reliability, the linkage pin joints feature a greased pin design with optional auto lube system.

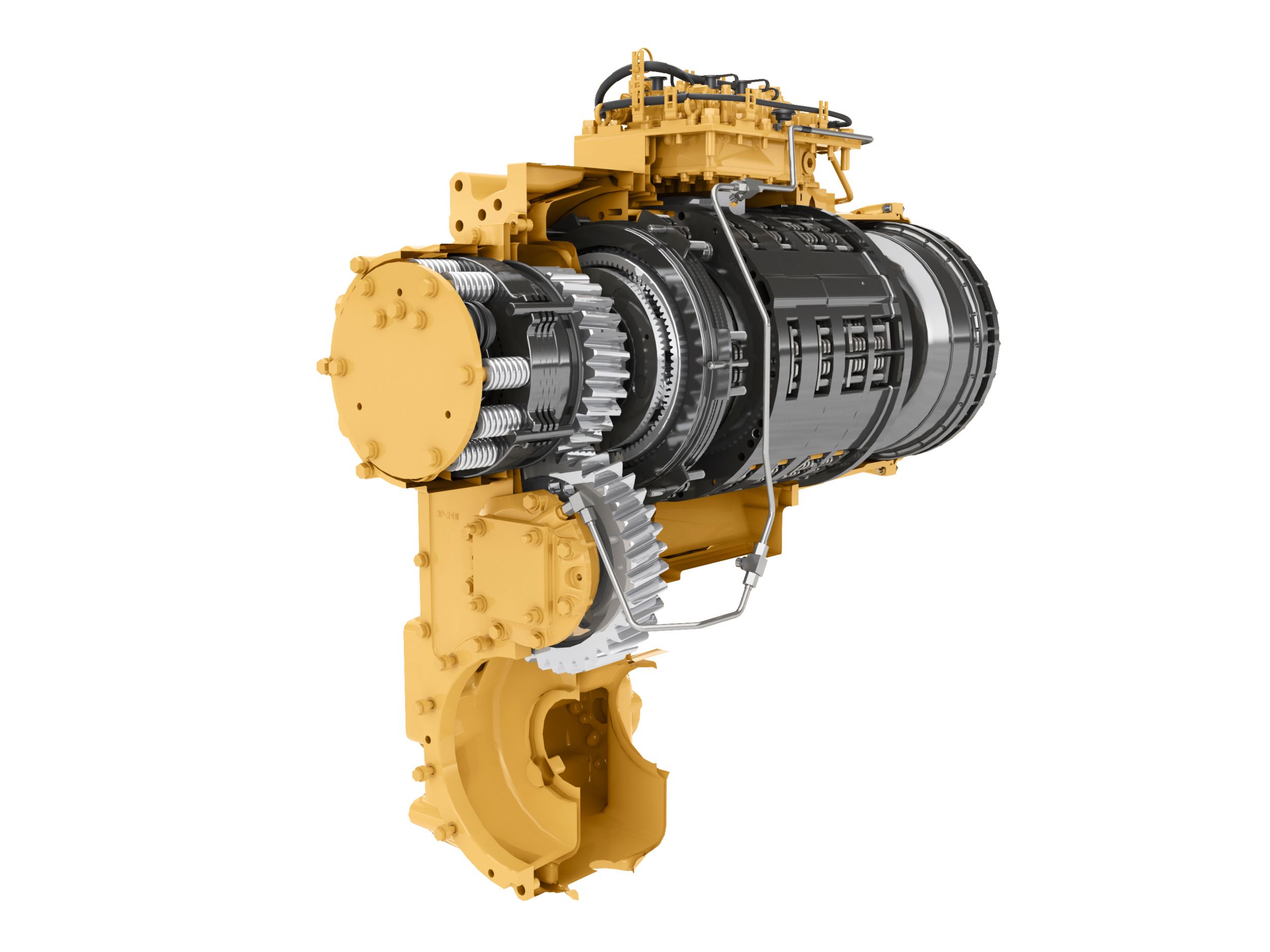

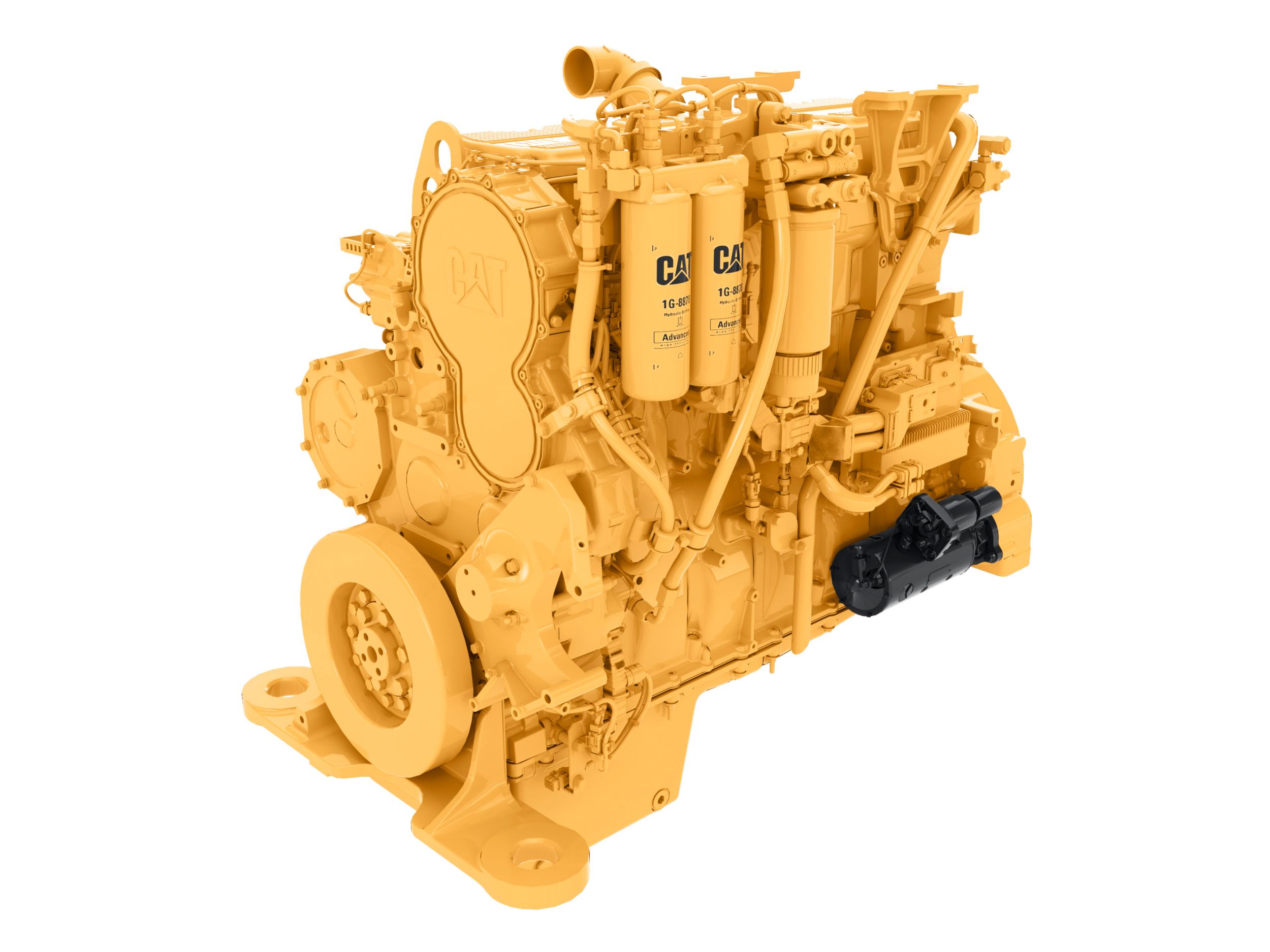

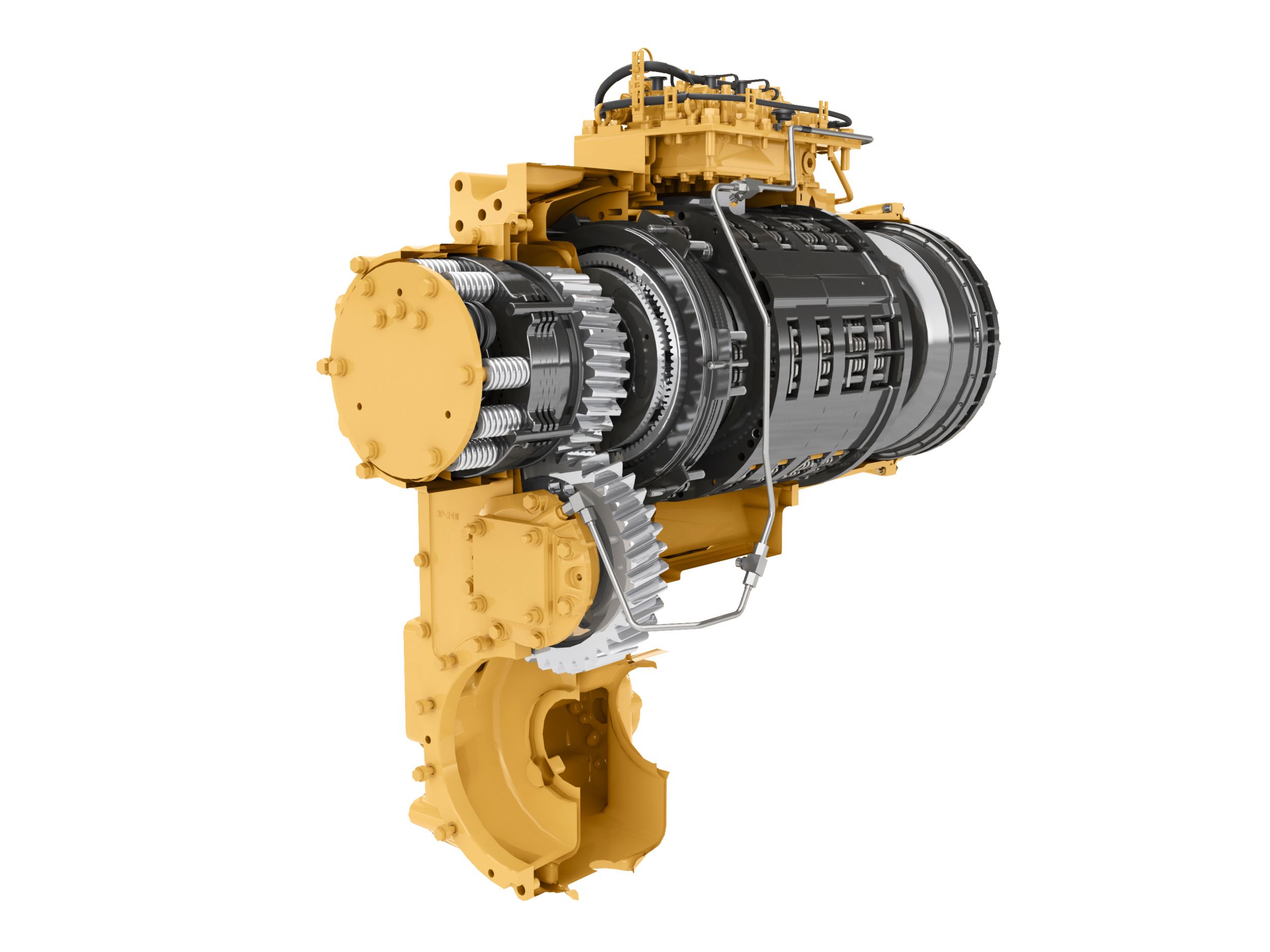

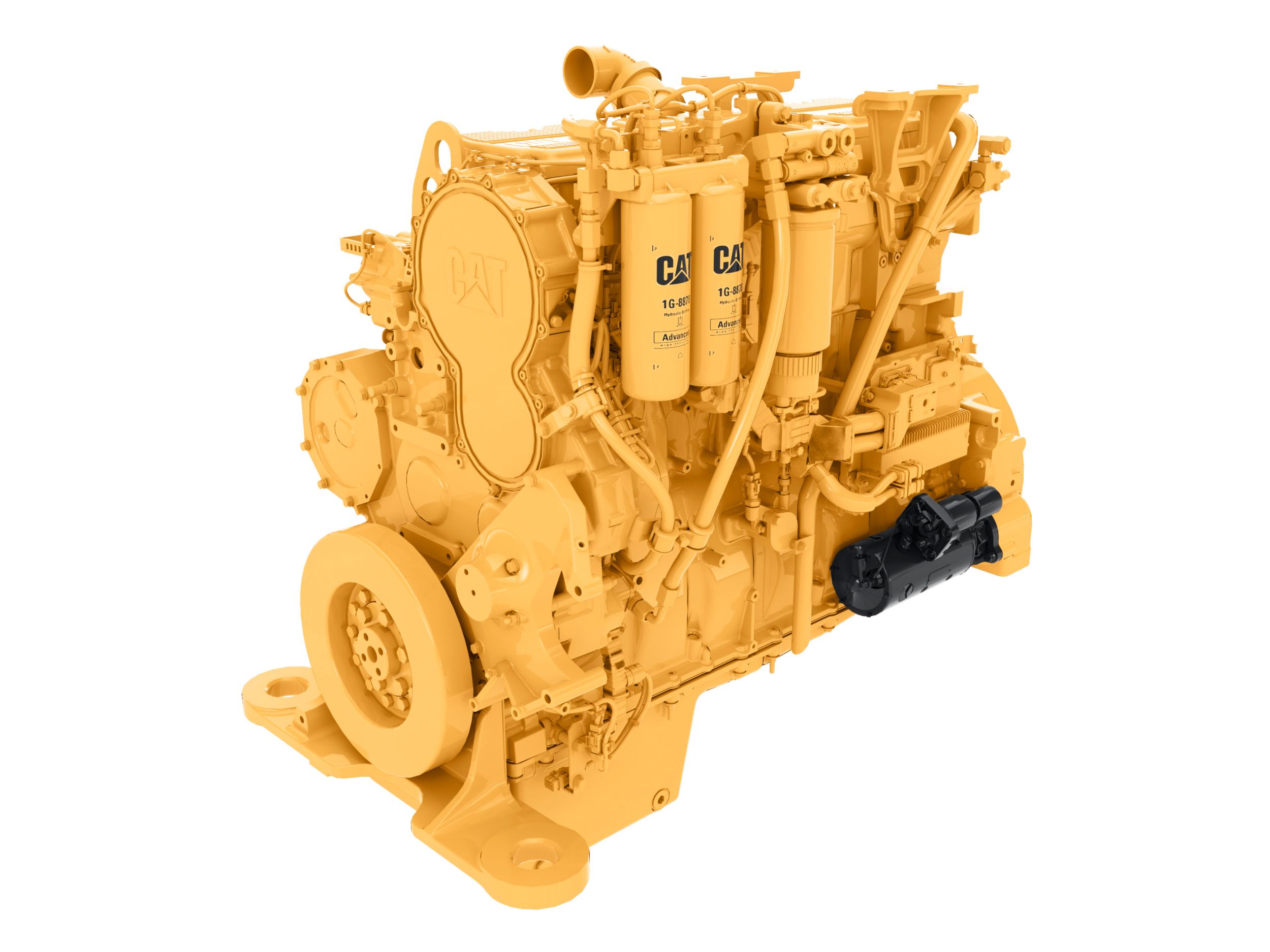

Power Train

Building your success begins with a best-in-class transmission designed specifically for mining applications.  Durability and efficiency at the heart of your 986H comes from the Cat C15 ACERT engine. Optimum performance is built in to this 6 cylinder turbocharged engine.

Durability and efficiency at the heart of your 986H comes from the Cat C15 ACERT engine. Optimum performance is built in to this 6 cylinder turbocharged engine.

- Consistent, smooth shifting and efficiency through integrated electronic controls.

- Heat treated gears and shafts extend component life and maximize reliability.

- Four forward and three reverse speeds to match your application.

Durability and efficiency at the heart of your 986H comes from the Cat C15 ACERT engine. Optimum performance is built in to this 6 cylinder turbocharged engine.

Durability and efficiency at the heart of your 986H comes from the Cat C15 ACERT engine. Optimum performance is built in to this 6 cylinder turbocharged engine.- Mechanically Actuated Electronic Unit Injection (MEUI™) controls injection pressure over the entire engine operating range. This gives the C15 ACERT engine complete control over injection timing, duration and pressure.

- Extended engine life through Cat components with proven reliability.

- The Advanced Diesel Engine Management (ADEM™) A4 electronic control module manages fuel delivery to optimize performance and provide quick engine response.

- Extends service brake life by neutralizing transmission as service brakes are applied.

- Allows full power to implement system while the machine is stationary during truck loading.

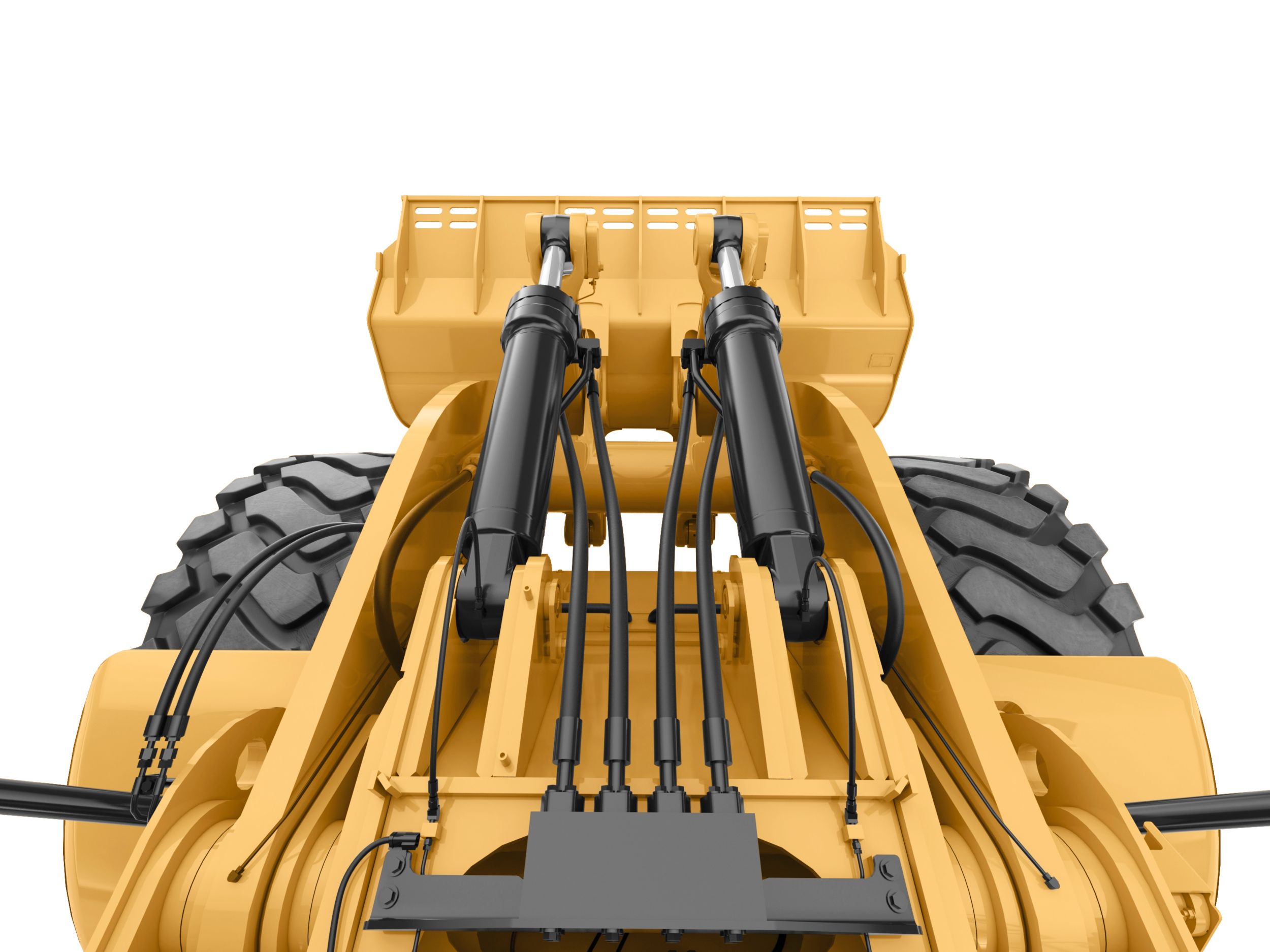

Hydraulics

Operators will be productive right away with our easy-to-use operator interface.  • Provides versatility through the ability to control a specialized attachment.

• Provides versatility through the ability to control a specialized attachment.

![]() Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.

Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.  Increase efficiency through our Load Sense Hydraulic System. Load sense hydraulics maximize performance by directing hydraulic fluid flow through implement and steering system only when needed.

Increase efficiency through our Load Sense Hydraulic System. Load sense hydraulics maximize performance by directing hydraulic fluid flow through implement and steering system only when needed.

- Comfortable soft detent implement controls.

- Low effort, responsive steering wheel.

- Easy-to-use, in-cab programmable lift kickout allows the operator to pre set linkage positions and achieve faster cycle times.

• Provides versatility through the ability to control a specialized attachment.

• Provides versatility through the ability to control a specialized attachment.

- Implement pump case drain filters.

- Implement system filter.

- Steering pump case drain filters.

- Power train oil filter.

Increase efficiency through our Load Sense Hydraulic System. Load sense hydraulics maximize performance by directing hydraulic fluid flow through implement and steering system only when needed.

Increase efficiency through our Load Sense Hydraulic System. Load sense hydraulics maximize performance by directing hydraulic fluid flow through implement and steering system only when needed. - Lowered fuel consumption.

- Consistent performance and efficiency with lower system heat.

Operator Station

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.  Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.

Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.  Your operator's productivity is enhanced with our clean, comfortable cab environment.

Your operator's productivity is enhanced with our clean, comfortable cab environment.

Enter and exit the cab easily and safely with these newly designed, ergonomic features.

Enter and exit the cab easily and safely with these newly designed, ergonomic features. - Punch stamped tread plates provide excellent footing.

- Spacious cab provides ample space for comfortable entry and exit.

- Angled access ladder.

Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.

Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat. - High back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod that moves with the seat.

- Optional heated seat for cold weather applications.

Your operator's productivity is enhanced with our clean, comfortable cab environment.

Your operator's productivity is enhanced with our clean, comfortable cab environment.

Technology Solutions

Cat Work Area Vision System (WAVS) enhances visibility around the job site through the use of a rear view camera. A camera mounted at the rear of the machine provides the input to the monitor display mounted in the front right corner of the cab, within the operators field of vision.

This includes a digital readout for gear selection and ground speed as well as gauge displays for:

This includes a digital readout for gear selection and ground speed as well as gauge displays for:

This includes a digital readout for gear selection and ground speed as well as gauge displays for:

This includes a digital readout for gear selection and ground speed as well as gauge displays for: - Fuel tank level.

- Engine and steering oil pressures.

- Engine coolant temperature.

- Torque converter and hydraulic oil temperature.

- Engine inlet air temperature.

Safety

We are constantly improving our products in an effort to provide a safe work environment for the operator and those who work on your job site.

![]()

![]()

- Walkways with non-skid surfaces are designed into the service areas.

- Windshield cleaning platforms provide safe and convenient access for the operator.

- Maintain three points of contact at all times through ground level or platform accessible service areas.

- Angled access ladder and strategically placed grab handles provide safe access and egress for the operator.

- Low interior sound levels.

- Cab mounted LED warning beacon.

- Optional heated seat.

- Optional HID lights provide optimal workspace visibility.

- Full Roll Over Protection System (ROPS) integrated into cab design.

Serviceability

- Longer service intervals on fluids and filters.

- Safe and convenient service with ground level or platform access and grouped service points.

- Centralized, ground level grease points for injecting grease into linkage pin joints.

- Centralized remote pressure taps for power train components.

- Ground electrical service center with emergency engine shutdown switch, battery disconnect switch and circuit breakers.

Customer Support

A valued partner, your Cat dealer is available whenever you need them. ![]()

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

Sustainability

Sustainability is designed and built into our 986H's features.![]()

- Engine Idle Shutdown can help you save fuel by avoiding unnecessary idling.

- Reduce waste with our maintenance free or extended maintenance batteries.

- To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost while benefiting the environment.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

System Match Efficiency

For full truck payloads with minimum loading time, an efficient loading/hauling system starts with a perfect match. Cat wheel loaders are matched with Cat articulated and off-highway trucks to maximize volume of material moved at the lowest operating cost per ton. The 986H equipped with the standard linkage is a perfect four pass match for the 770G (38.6 tonnes/42.6 tons). The 986H equipped with a high lift linkage is capable of loading a 772G (47.7 tonnes/52 tons) in 5 passes and a 773E or 773G (56 tonnes/61.7 tons) in 6 passes.

![]()

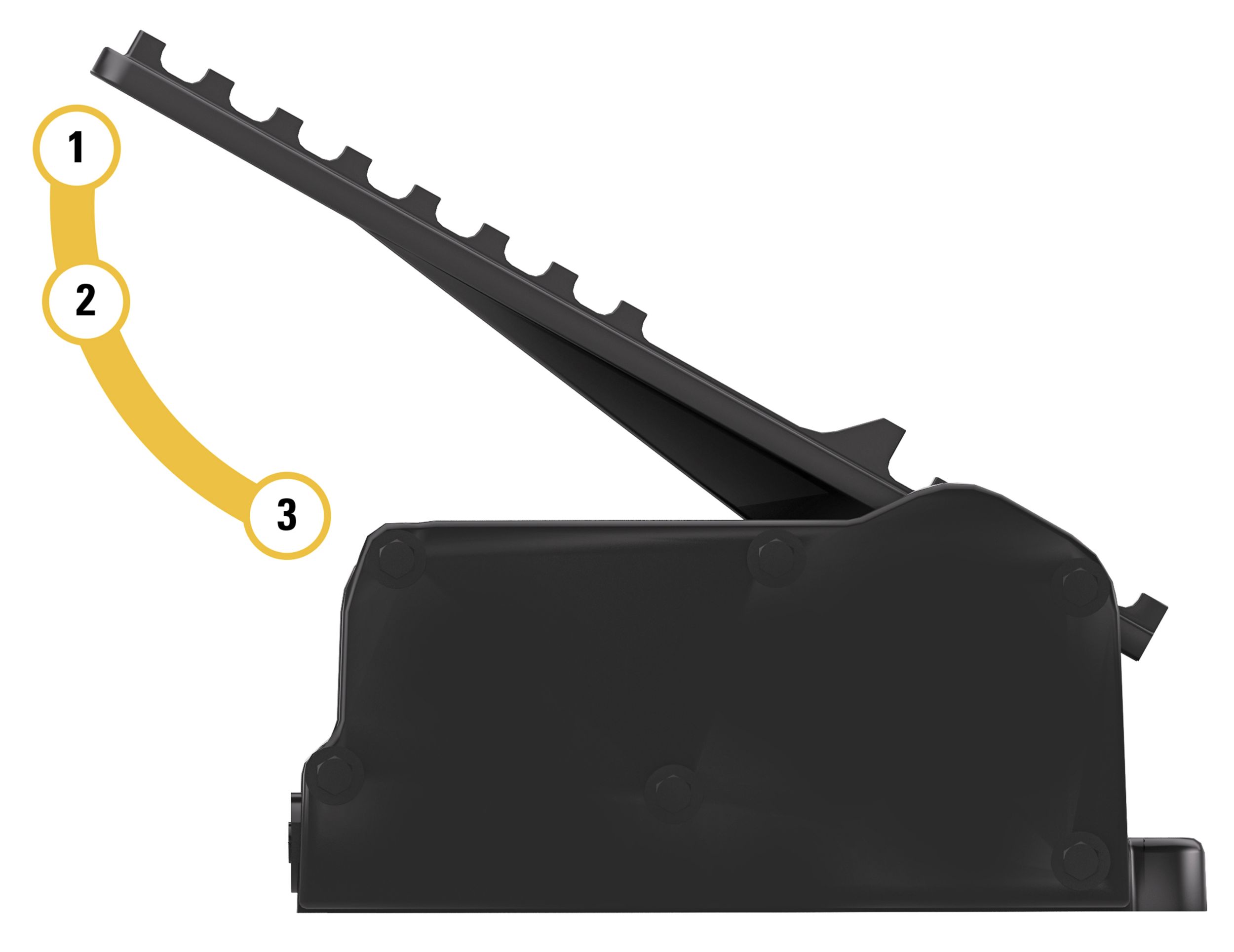

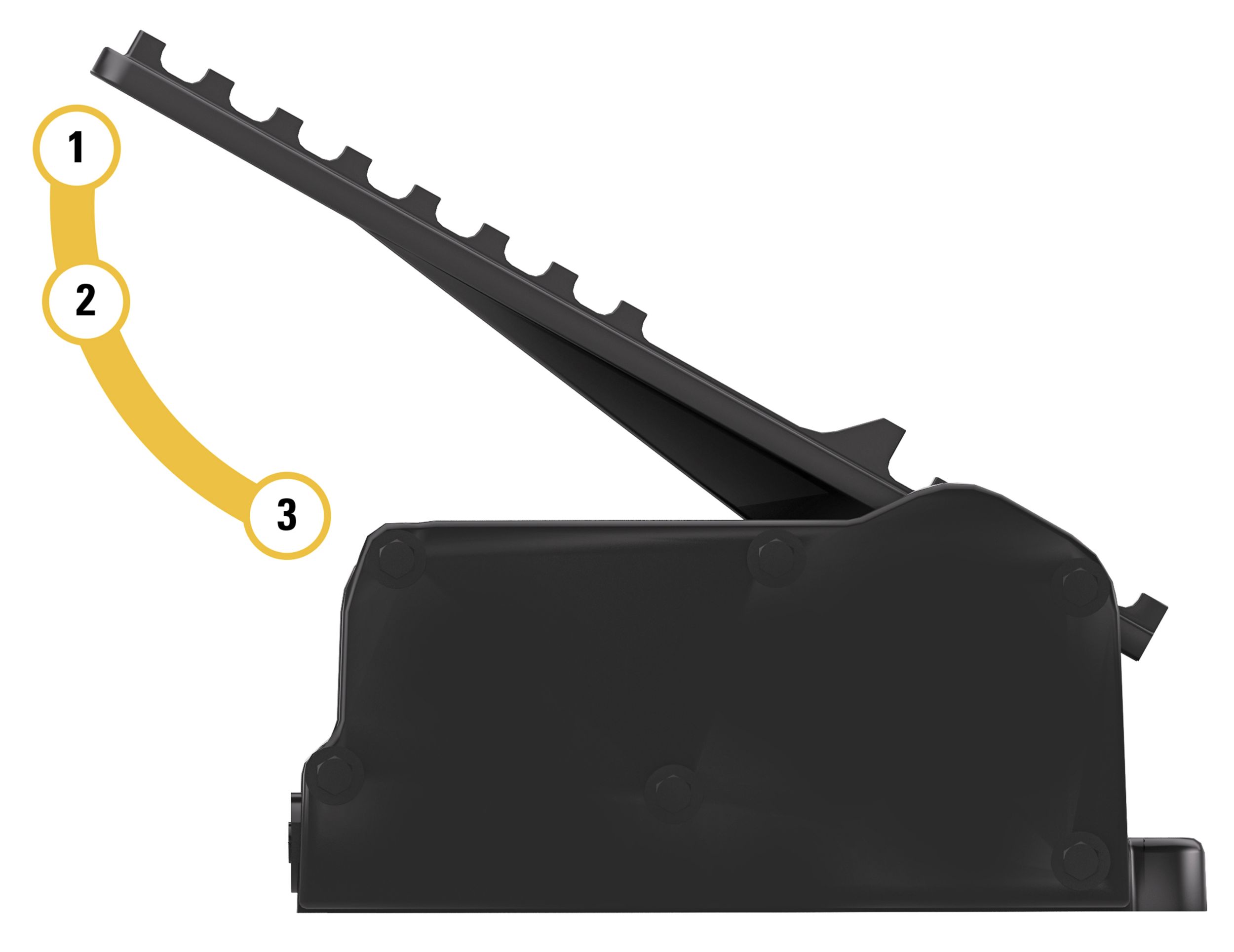

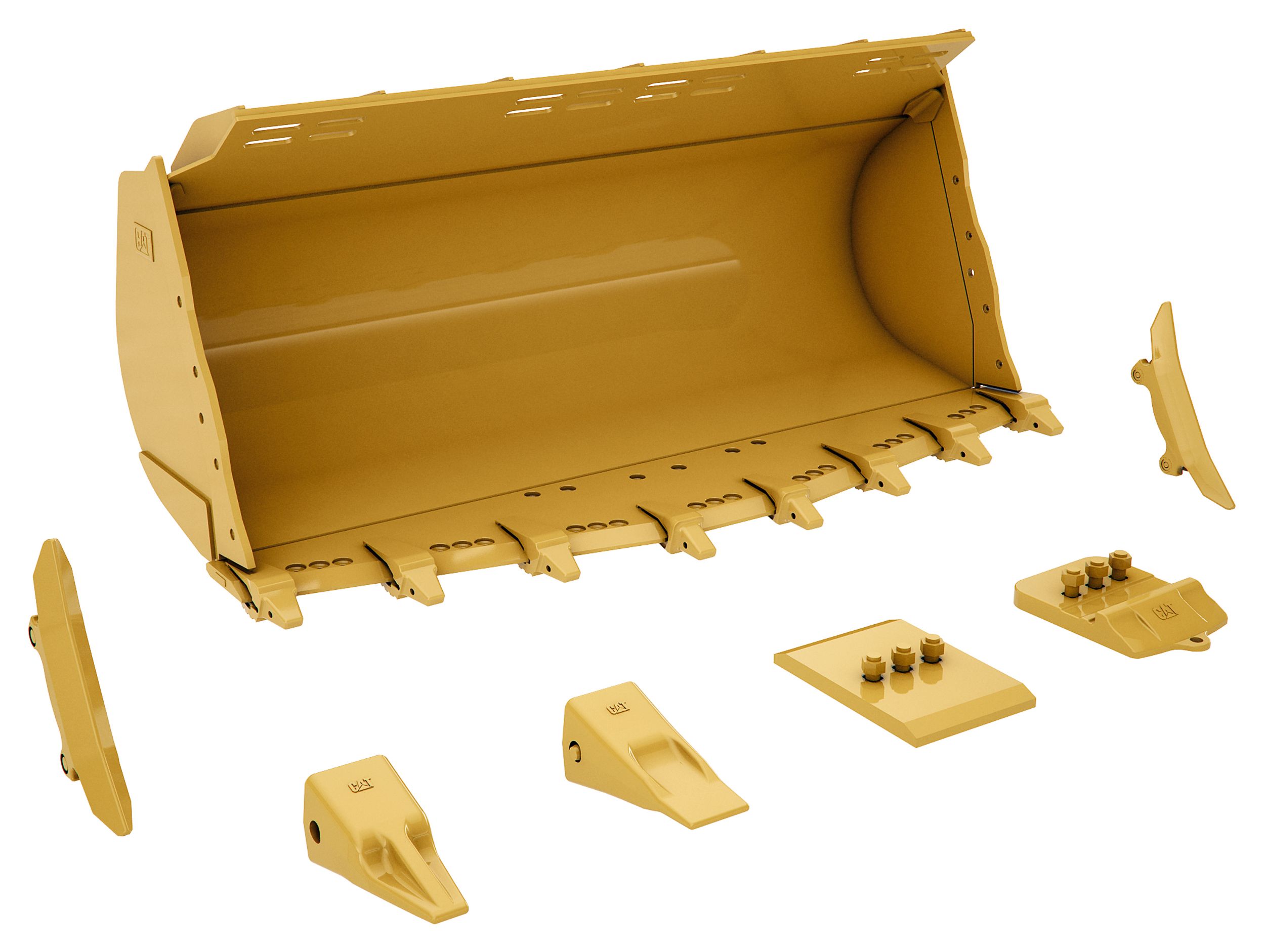

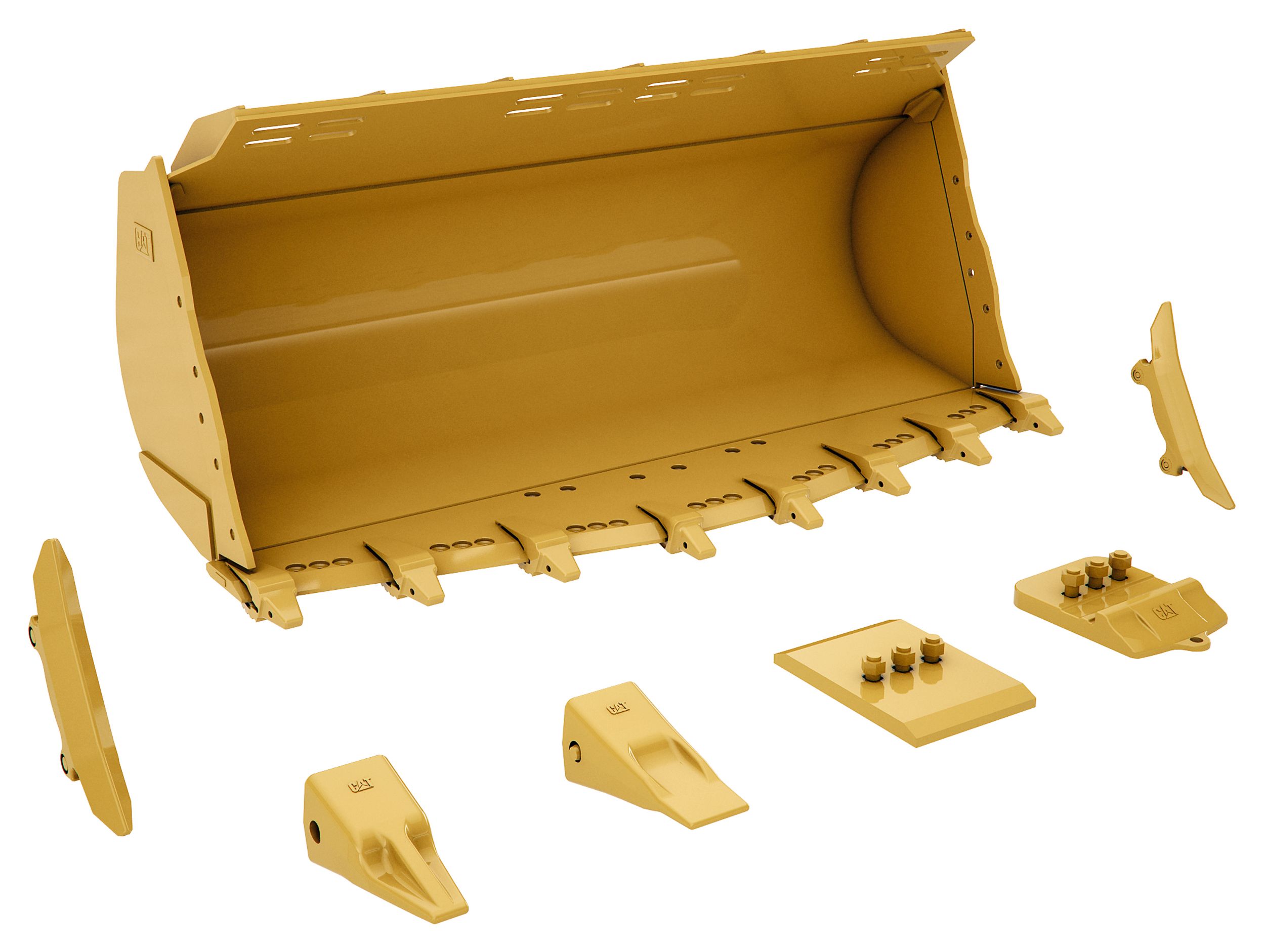

Bucket Ground Engaging Tools

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 986H buckets are manufactured with the Performance Series design.

![]() Applications: Face loading tightly compacted pit materials.

Applications: Face loading tightly compacted pit materials.

![]() Applications: Loading loose, stockpiled material.

Applications: Loading loose, stockpiled material.

![]() The optional quick coupler allows the operator to quickly switch between multiple work tools, making the 986H highly versatile.

The optional quick coupler allows the operator to quickly switch between multiple work tools, making the 986H highly versatile.

![]() Multiple GET options are available to customize your 986H to your application, such as:

Multiple GET options are available to customize your 986H to your application, such as:  Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you. For a full list of Cat GET please visit http://www.cat.com/get.

Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you. For a full list of Cat GET please visit http://www.cat.com/get.

![]()

- Sidebar protectors.

- General duty and penetration tips.

- Standard and half arrow segments.

Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you. For a full list of Cat GET please visit http://www.cat.com/get.

Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you. For a full list of Cat GET please visit http://www.cat.com/get.

SPECIFICATIONS

- Net Power 305.0kW

- Engine Model Cat® C15 ACERT™

- Bore 137mm

- Stroke 171.5mm

- Displacement 15.2l

- Torque Rise 37%

- Rated Speed 1,800 rpm

- Net Power - SAE J1349:2011 305kW

- Gross Power - SAE J1995:2014 335kW

- Peak Torque - 1,200 rpm 2320N·m

- Gross Power - ISO 14396 329kW

- Operating Weight 43717kg

- Bucket Capacity Range 5-10.3 m3 (6.5-13.5 yd3)

- Cat Truck Match - High Lift 772

- Rated Payload - Loose Material (High Lift) 11t

- Rated Payload - Quarry Face 10t

- Cat Truck Match - Standard 770

- Rated Payload - Loose Material (Standard) 12.7t

- Transmission Type Cat planetary power shift

- Forward - 1 7.3km/h

- Forward - 2 12.2km/h

- Reverse - 1 7.6km/h

- Reverse - 2 13.6km/h

- Direct Drive - Forward 4 39.0km/h

- Direct Drive - Reverse 2 14.1km/h

- Direct Drive - Forward 3 22.0km/h

- Direct Drive - Reverse 3 25.0km/h

- Direct Drive - Forward 2 12.7km/h

- Lift Cylinder - Bore 190.0mm

- Lift Cylinder - Stroke 1138.0mm

- Tilt Cylinder - Stroke 722.0mm

- Maximum Flow at 2,165 rpm 470.0l/min

- Lift/Tilt System - Pump 2 × 110 cc variable displacement

- Tilt Cylinder - Bore 170.0mm

- Lift/Tilt System - Circuit Load Sense

- Relief Valve Setting - Lift/Tilt 27900.0kPa

- Rack Back 4.5s

- Raise 9s

- Dump 3.5s

- Total Hydraulic Cycle Time 21.3s

- Lower Float Down 4.3s

- Lower 5.2s

- Fuel Tank 600.0l

- Crankcase 34.0l

- Transmission 75.0l

- Hydraulic System - Tank Only 125.0l

- Axle Oil 356.0l

- Hydraulic System Factory Fill 330.0l

- Differential - Final Drives - Rear 170.0l

- Cooling Systems 90.0l

- Differential - Final Drives - Front 186.0l

- Bucket Capacities 5-10.3 m3 (6.5-13.5 yd3)

- Front Fixed

- Rear Trunnion

- Oscillation Angle ±12.5°

- Brakes SAE J1473 OCT90, ISO 3450:1992

- Maximum Flow at 2,284 rpm 200.0l/min

- Total Steering Angle 70°

- Steering Cut Off Pressure 27600.0kPa

- Steering System - Pump Piston, variable displacement

- Steering System - Circuit Load Sense

PRODUCT BROCHURES AND MORE ARE READY TO DOWNLOAD!

Caterpillar product brochures and other informational documents are available for your growing business.

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER SYSTEMS

MARINE POWER SYSTEMS

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS