| Minimum Rating | 262 bkW352 BHP |

| Maximum Rating | 874 bkW1172 BHP |

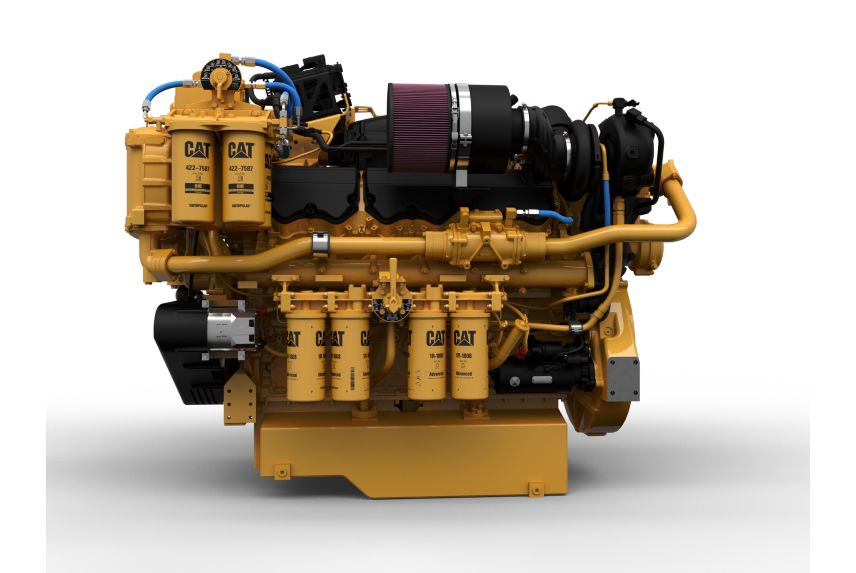

| Aspiration | Turbocharged-aftercooled aspiration |

| Bore | 145 mm5.71 in |

| Configuration | Vee 12, 4-stroke-cycle diesel |

| Displacement | 32.1 l1959 in³ |

| Rotation | Counterclockwise from flywheel end |

| Stroke | 162 mm6.38 in |

| Maximum Engine Dry Weight | 3248 kg7160 lb |

| Maximum Height | 1613 mm63.5 in |

| Maximum Length | 2280 mm89.8 in |

| Maximum Width | 1455 mm57.3 in |

| Minimum Engine Dry Weight | 3152 kg6950 lb |

| Minimum Height | 1507 mm59.3 in |

| Minimum Length | 2130 mm83.9 in |

| Minimum Width | 1451 mm57.1 in |

| Emissions | IMO III emissions certified (SCR required) |

| 6 Brick U-Flow - Height | 597 mm23.5 in |

| 6 Brick U-Flow - Length | 2159 mm85 in |

| 6 Brick U-Flow - Weight | 560 kg1235 lb |

| 6 Brick U-Flow - Width | 1445 mm56.9 in |

| 6 Brick Z-Flow - Height | 597 mm23.5 in |

| 6 Brick Z-Flow - Length | 3751 mm147.7 in |

| 6 Brick Z-Flow - Weight | 565 kg1246 lb |

| 6 Brick Z-Flow - Width | 1106 mm43.5 in |

| Dosing Cabinet - Height | 579 mm22.8 in |

| Dosing Cabinet - Length | 949 mm37.4 in |

| Dosing Cabinet - Weight | 95 kg209 lb |

| Dosing Cabinet - Width | 477 mm18.8 in |

| Cooling | Heat exchanger or keel cooled |

| Flywheel Housing | SAE No. 0 with SAE No. 18 flywheel (136 teeth) |

| Governor | Electronic (A5 ECM) |

| Oil Change Interval | 750 hrs - deep pan |

| Rated Engine Speed | 1500 rpm |

| Refill Capacity | Lube Oil System w/ oil filter change: 146 L (38.5 gal) - deep pan |