| Net Power | 403 kW541 HP |

| Engine Model | Cat® C18 ACERT™ |

| Bore | 145 mm5.7 in |

| Stroke | 183 mm7.2 in |

| Displacement | 18.1 l1105 in³ |

| Torque Rise | 58 %58 % |

| Rated Speed | 1,700 rpm |

| Emissions | U.S. EPA Tier 4 Final/EU Stage IV OR Tier 3/Stage IIIA Equivalent OR Tier 2/Stage II Equivalent |

| Gross - ISO 14396 | 432 kW580 HP |

| Net Power - SAE J1349 | 403 kW541 HP |

| Peak Power Speed | 1,500 rpm |

| Peak Power Speed - 1,500 rpm - Gross - ISO 14396 | 432 kW580 HP |

| Peak Power Speed - 1,500 rpm - Gross - SAE J1995 | 439 kW588 HP |

| Peak Power Speed - 1,500 rpm - Net Power - SAE J1349 | 403 kW541 HP |

| Peak Torque - 1,200 rpm | 2852 N·m2104 lb/ft |

| Operating Weight | 51062 kg112574 lb |

| Bucket Capacity Range | 4.7-13 m3 (6.2-17 yd3) |

| Cat Truck Match - High Lift | 773-775 |

| Cat Truck Match - Standard | 770-772 |

| Rated Payload - Loose Material | 14.5 t16 t |

| Rated Payload - Quarry Face | 11.3 t12.5 t |

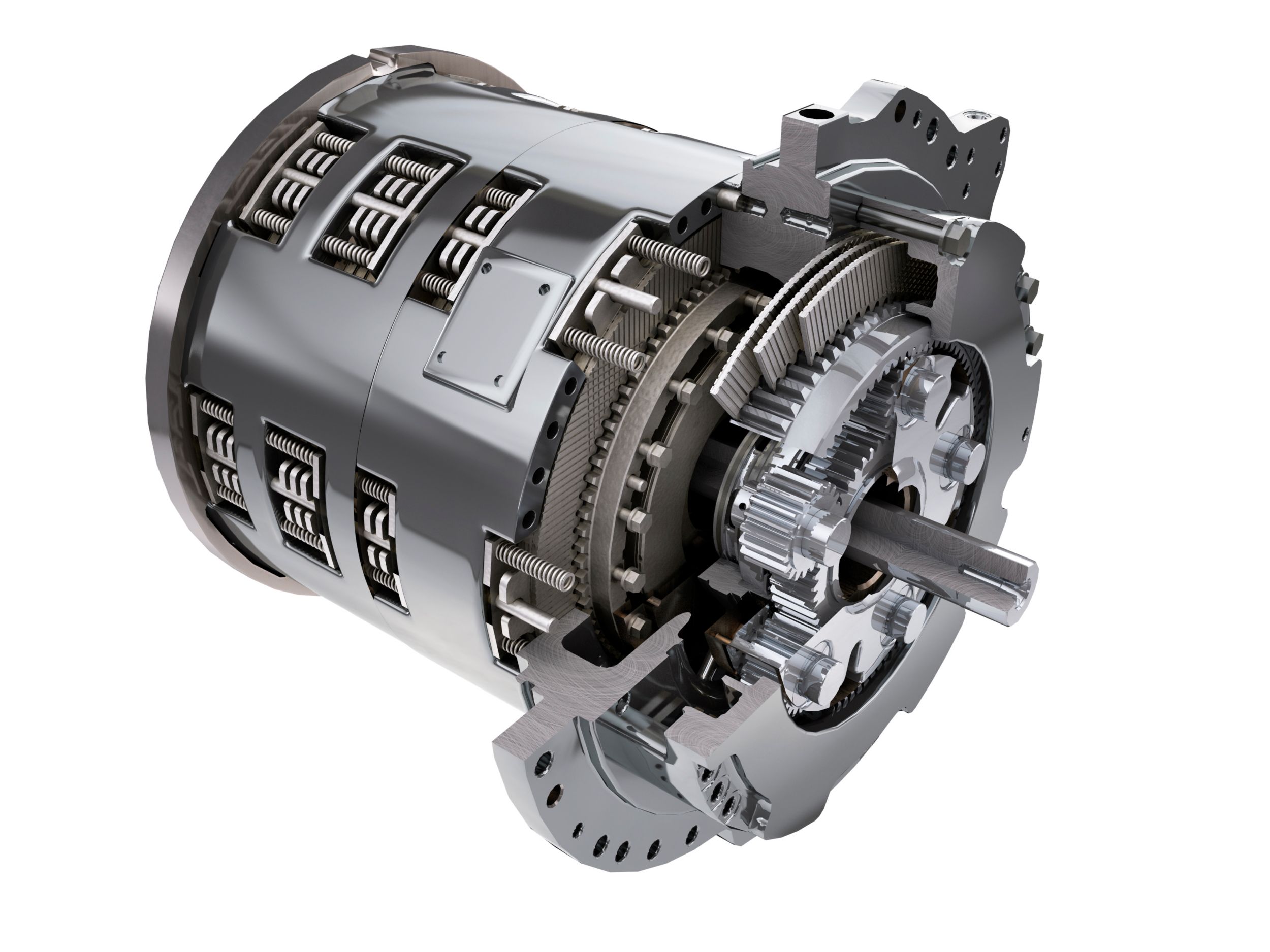

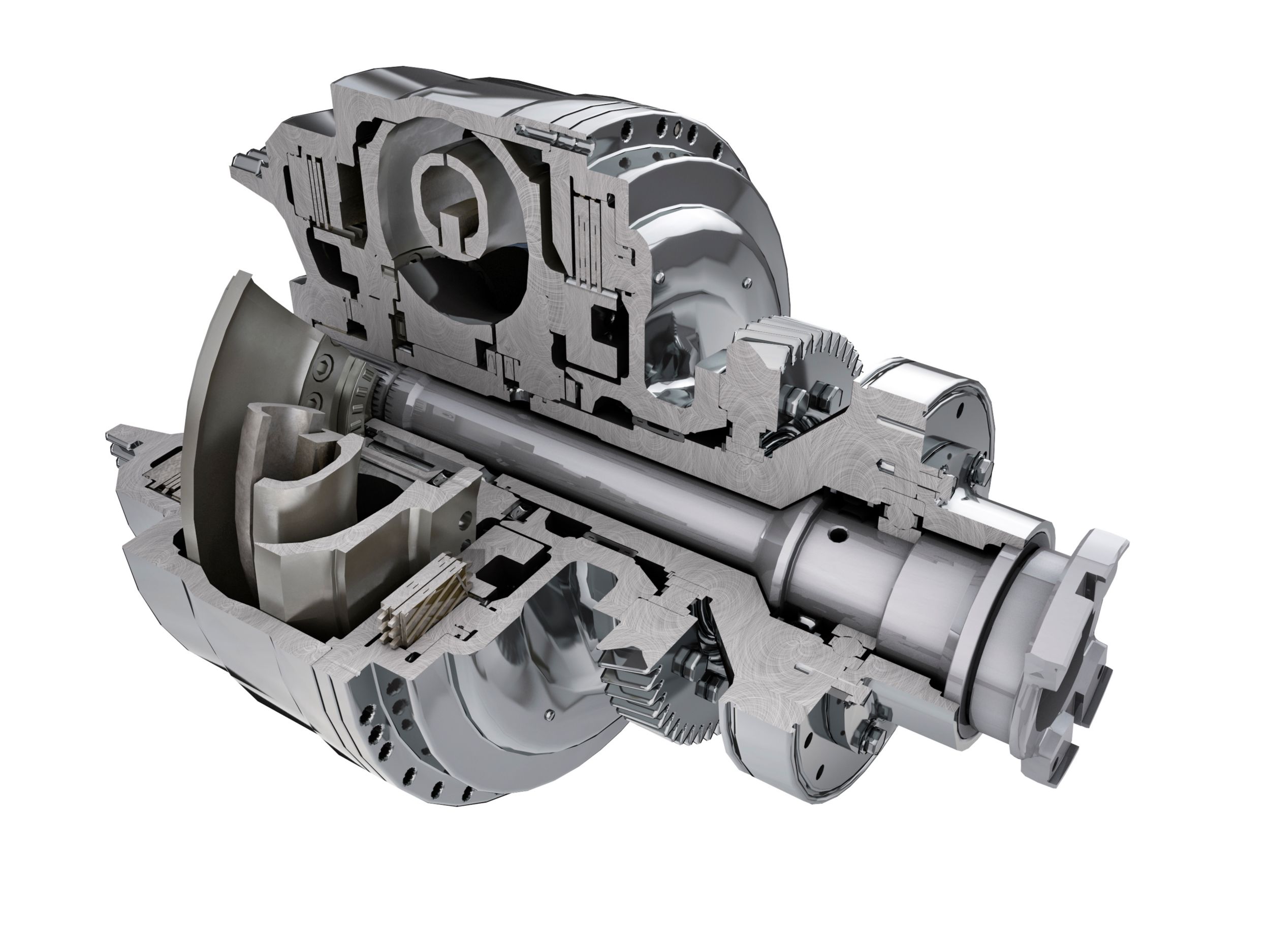

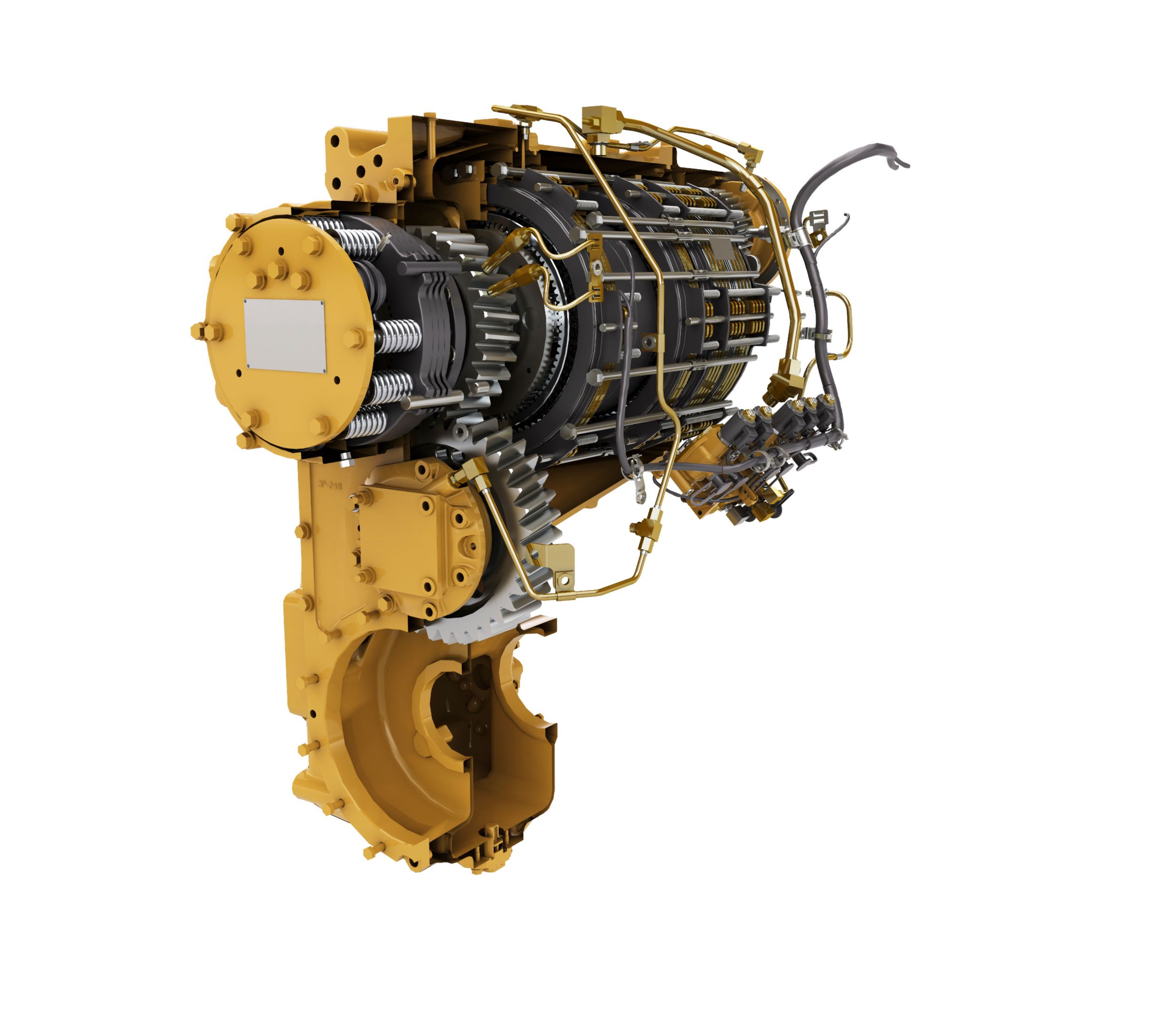

| Transmission Type | Cat planetary power shift |

| Forward - 1 | 6.5 km/h4 mile/h |

| Forward - 2 | 11.6 km/h7.2 mile/h |

| Forward - 3 | 20.4 km/h12.7 mile/h |

| Forward - 4 | 34.7 km/h21.6 mile/h |

| Reverse - 1 | 7.5 km/h4.7 mile/h |

| Reverse - 2 | 13.3 km/h8.3 mile/h |

| Reverse - 3 | 23.2 km/h14.4 mile/h |

| Direct Drive - Forward 1 | Lock-up disabled |

| Direct Drive - Forward 2 | 12.5 km/h7.8 mile/h |

| Direct Drive - Forward 3 | 22.3 km/h13.9 mile/h |

| Direct Drive - Forward 4 | 39.3 km/h24.4 mile/h |

| Direct Drive - Reverse 1 | 8 km/h5 mile/h |

| Direct Drive - Reverse 2 | 14.3 km/h8.9 mile/h |

| Direct Drive - Reverse 3 | 25.5 km/h15.8 mile/h |

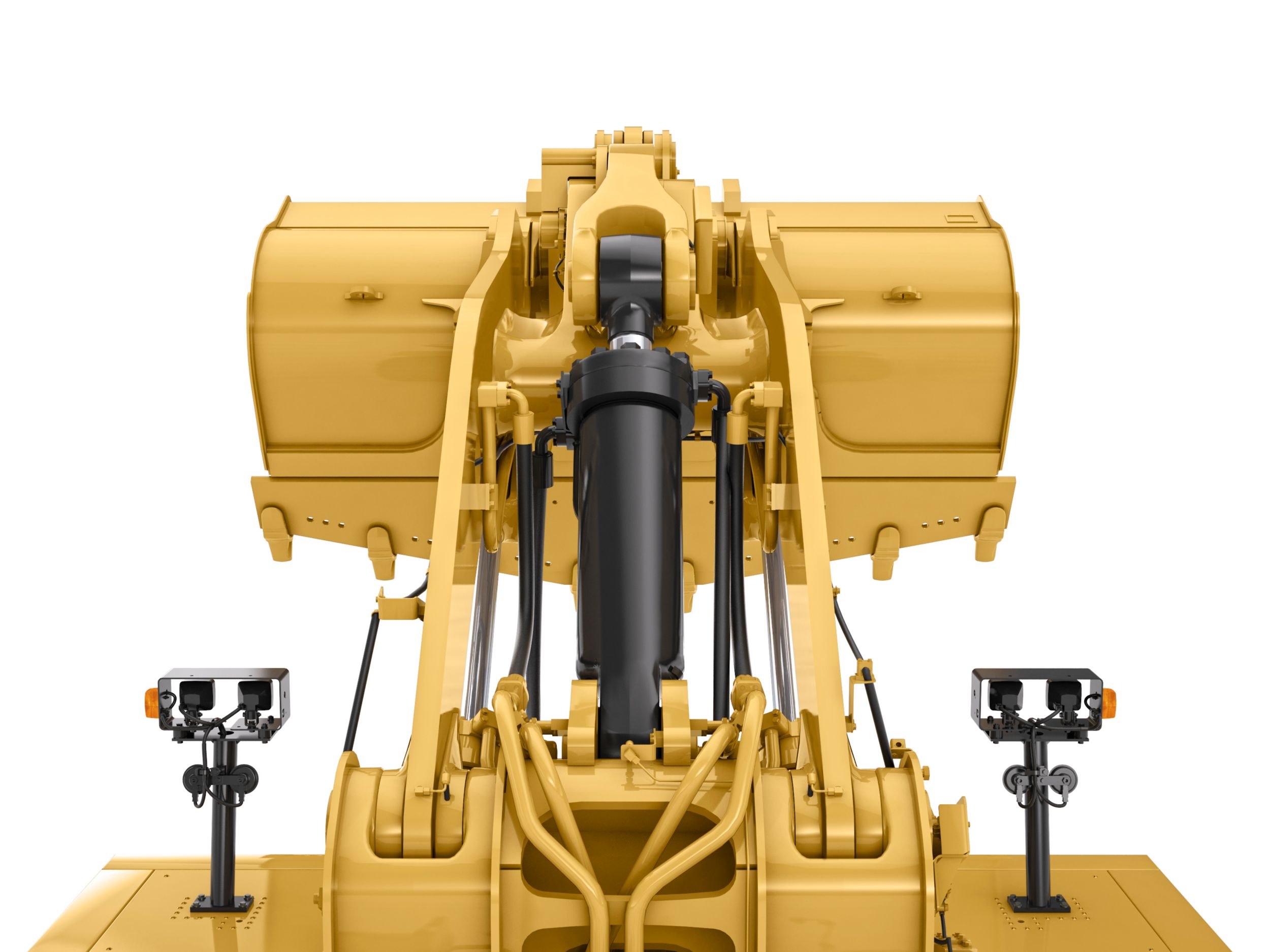

| Cylinders, Double Acting - Lift, Bore and Stroke | 210 mm × 1050 mm (8.7 in × 41.3 in) |

| Cylinders, Double Acting - Tilt, Bore and Stroke | 269 mm × 685 mm (8.7 in × 27 in) |

| Lift/Tilt System | Variable displacement piston |

| Lift/Tilt System - Circuit | EH- Positive Flow Control, Flow Sharing |

| Maximum Flow | 52 l/min13.7 gal/min |

| Maximum Flow at 1,400-1,860 rpm | 580 l/min153 gal/min |

| Pilot System | Variable displacement piston |

| Relief Valve Setting | 3800 kPa551 psi |

| Relief Valve Setting - Lift/Tilt | 32800 kPa4757 psi |

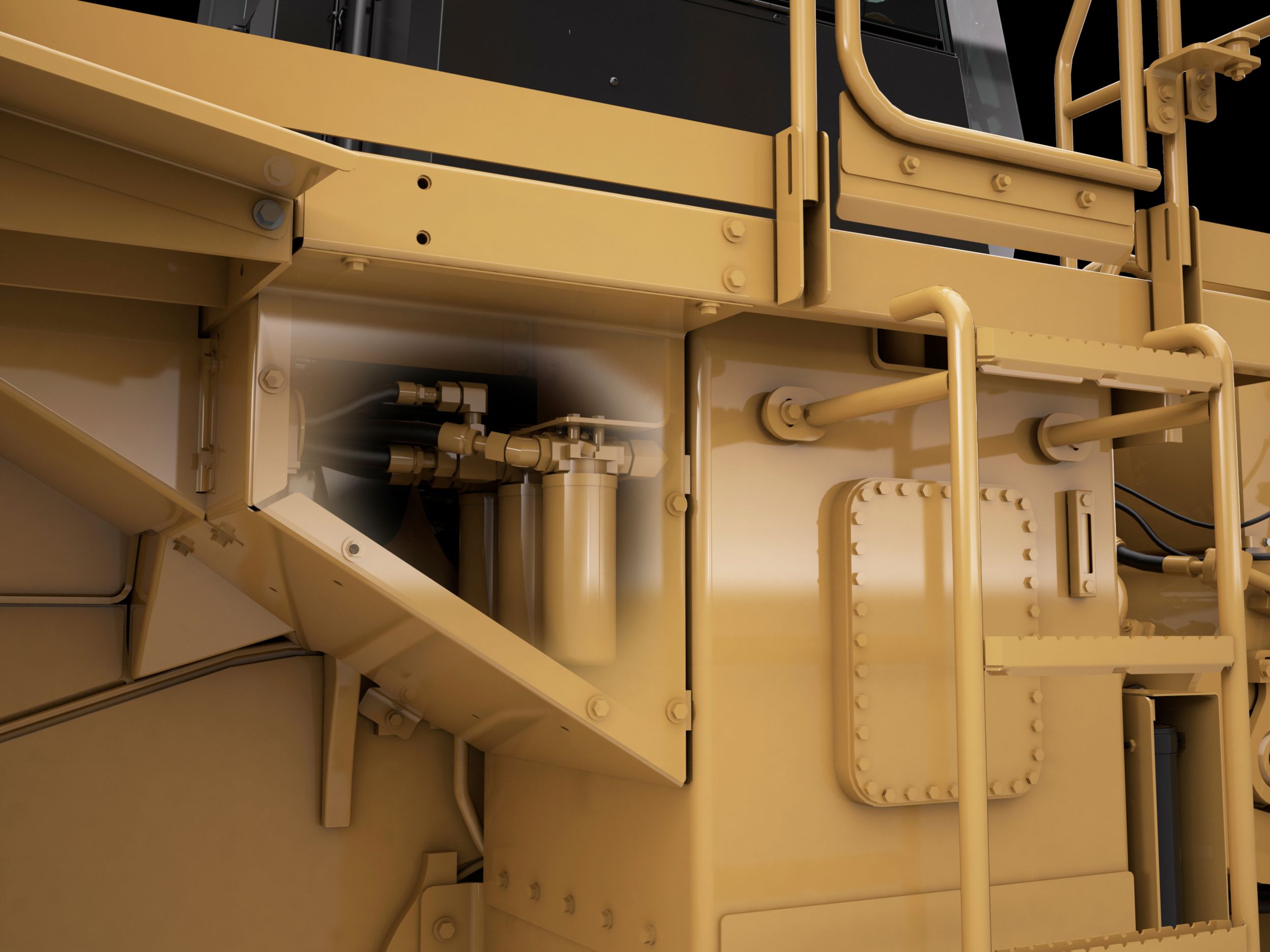

| Fuel Tank | 712 l188 gal (US) |

| Cooling System | 120 l31.7 gal (US) |

| Crankcase | 60 l15.9 gal (US) |

| Transmission | 120 l31.7 gal (US) |

| Hydraulic System - Tank Only | 240 l63.4 gal (US) |

| Diesel Exhaust Fluid Tank (For Tier 4 Final/Stage IV Only) | 33 l8.7 gal (US) |

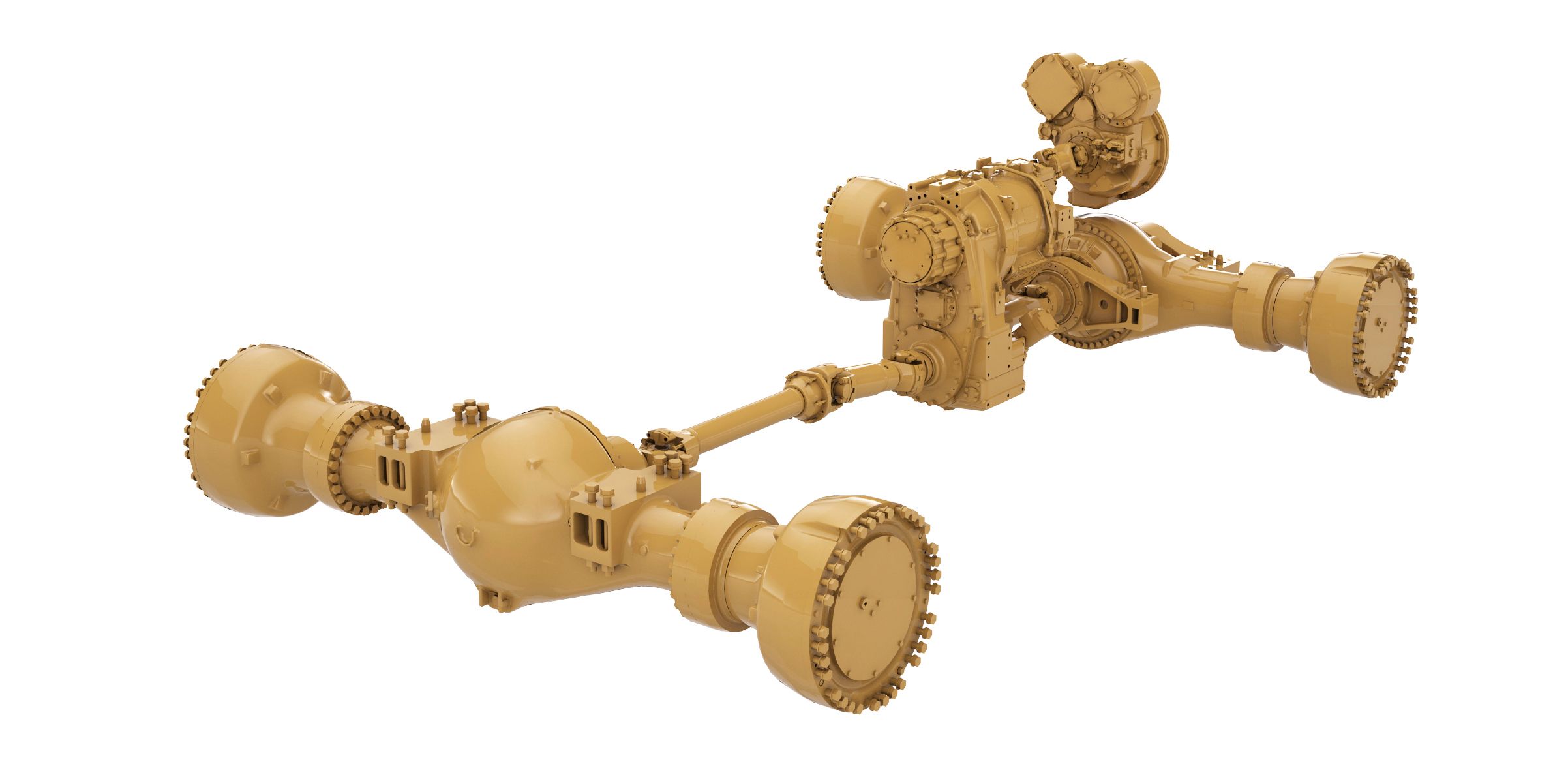

| Differential - Final Drives - Front | 186 l49.1 gal (US) |

| Differential - Final Drives - Rear | 186 l49.1 gal (US) |

| Hydraulic System Factory Fill | 475 l125.5 gal (US) |

| Bucket Capacities | 4.7-13 m3 (6.2-17 yd3) |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | 13° |

| Brakes | SAE J1473 OCT90, ISO 3450:1992 |

| Maximum Flow | 270 l/min71.3 gal/min |

| Relief Valve Setting - Steering | 30000 kPa4351 psi |

| Steering Cycle Times - High Idle | 3.4 s3.4 s |

| Steering Cycle Times - Low Idle | 5.6 s5.6 s |

| Steering System - Circuit | Pilot, load sensing |

| Steering System - Pump | Piston, variable displacement |

| Total Steering Angle | 86° |

| Dump | 2.2 s2.2 s |

| Lower Float Down | 3.5 s3.5 s |

| Rack Back | 4.5 s4.5 s |

| Raise | 8 s8 s |

| Total Hydraulic Cycle Time - Empty Bucket | 18.2 s18.2 s |

| Machine Sound Level (ISO 6395) | 111 dB(A)111 dB(A) |

| Operator Sound Level (ISO 6396) | 72 dB(A)72 dB(A) |

| Machine Sound Level (ISO 6395) | 109 dB(A)109 dB(A) |

| Operator Sound Level (ISO 6396) | 72 dB(A)72 dB(A) |

| Coolant (Validated by Test Cell Fill Quantities) | 125 l33 gal (US) |

| Transmission - Validated by Test Cell Fill Quantities | 110 l29 gal (US) |

| Machine Sound Level (ISO 6395) | 112 dB(A)112 dB(A) |

| Operator Sound Level ( ISO 6396) | 73 dB(A)73 dB(A) |

| Machine Sound Level (ISO 6395) | 110 dB(A)110 dB(A) |

| Operator Sound Level (ISO 6396) | 72 dB(A)72 dB(A) |