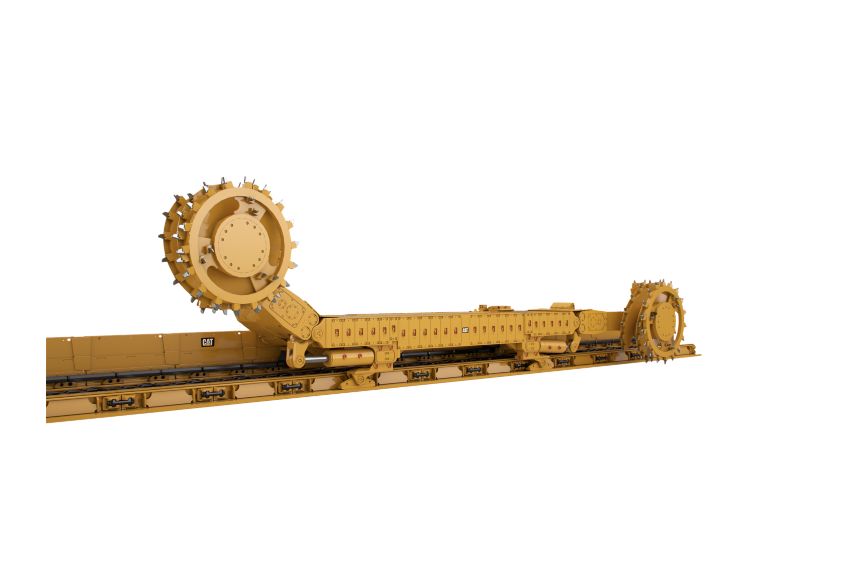

| Typical Machine Length | 13.75 m45.1 ft |

| Installed Power | 1900 kW2548 HP |

| Haulage System | AC |

| Applicable Minimum Pan Width | 1032 mm40.6 in |

| Available Cutting Power | 2 × 500 kW (2 × 671 hp); 2 × 620 kW (2 × 831 hp); 2 × 750 kW (2 × 1,006 hp) |

| Available Haulage Motors | 2 × 125 kW (2 × 168 hp) |

| Body Height | 520 mm20.5 in |

| Cutting Drum Diameter | 1.40-2.30 m (55-91 in) |

| Haulage Pull | Up to 920 kN/206,824 lbf (Up to 91 tonnes/100 tons) |

| Haulage Speed | Up to 32 m/min (Up to 105 ft/min) |

| Height Range | 1.80-4.50 m (71-177 in) |

| Machine Weight - Approximate | 70 ton (US)77 ton (US) |

| Operating Voltage | 2300V, 3300V, 4160V |

| Pump Motor | 50 kW67 HP |

| Available Cutting Power | 2 x 500 kW (2 x 671 hp); 2 x 620 kW (2 x 831 hp); 2 x 750 kW (2 x 1,006 hp) |

| Body Height | 600 mm23.6 in |

| Cutting Drum Diameter | 1600-2500 mm (63-98.5 in) |

| Cutting Drum Speed | 32.8, 37.4 and 45.2 rpm |

| Haulage Motor | 2 x 125 kW (2 x 168 hp) |

| Haulage Pull | Up to 945 kN (96 tons) |

| Haulage Speed | Up to 30.1 m/min (98.8 ft/min) |

| Haulage System | AC inverter drive |

| Installed Power | Up to 1780 kW (Up to 2,387 hp) |

| Machine Weight - Approximate | 70 ton (US)69 ton (US) |

| Minimum Pan Width | 1032 mm40.6 in |

| Operating Voltage | 3300 V3300 V |

| Pump Motor | 30 kW40 HP |

| Seam Range | 1.8-4.5 m (71-177 in) |

| Typical Machine Length - Drum Centers | 14155 mm46.4 ft |

| Available Cutting Power | 2 x 597 kW (2 x 800 hp); 2 x 746 kW (2 x 1,000 hp); 2 x 895 kW (2 x 1,200 hp) |

| Body Height | 600 mm23.6 in |

| Cutting Drum Diameter | 1600-2500 mm (63-98.5 in) |

| Cutting Drum Speed | 39.4, 44.9 and 54.3 rpm |

| Haulage Motor | 2 x 125 kW (2 x 168 hp) |

| Haulage Pull | Up to 1049 kN (107 tons) |

| Haulage Speed | Up to 30 m/min (98.5 ft/min) |

| Haulage System | AC inverter drive |

| Installed Power | Up to 1780 kW (Up to 2,387 hp) |

| Machine Weight - Approximate | 78 ton (US)77 ton (US) |

| Minimum Pan Width | 1032 mm40.6 in |

| Operating Voltage | 4160 V4160 V |

| Pump Motor | 30 kW40 HP |

| Seam Range | 1.8-4.5 m (71-177 in) |

| Typical Machine Length - Drum Centers | 14082 mm46.2 ft |

| Type (1) | Operating system pressure of 260 bar (3,770 psi) |

| Type (2) | Integral monitoring transducers |

| Type (3) | For use with ISO 68 or ISO 100 hydraulic oils |

| Type (4) | Robust hydraulic reservoir of 165 L (43.6 gal) capacity |

| Type (5) | This unit has a pump motor rating of 30 kW @ 50 Hz (48 hp @ 60 Hz) |

| Type (6) | Fixed displacement pump, with a capacity of 50 L/min (13.21 gal/min) |

| Type (7) | Available with 6 section valve bank |

| Type (1) | This flameproof module contains the majority of the shearer electrical control and power distribution components. |

| Type (2) | High current carrying capacity of 400 amps and can accommodate trailing cables up to 185 mm2 (2.9 in2). |

| Type (3) | All internal chassis can be ‘bench built,' tested and stored. |

| Type (4) | This unit also contains high voltage (HV) fuses, earth leakage and a visible disconnect. |

| Type (5) | An extremely powerful PMC Evo-S control system with state-of-the-art Ethernet communication and backup functionality. |

| Type (6) | This unit contains cutter motor contactors, circuit breakers, control transformer and current monitoring. |

| Type (7) | Box contains various low voltage (LV) circuit breakers which can be reset through the flame proof (FLP) cover, reducing downtime |

| Type (1) | Module contains drive system circuit breaker and one 250 kW, 600V AC inverter drive, with regenerative braking module. |

| Type (2) | This flameproof module contains the main 253 kVA haulage transformer, power supplies and auxiliary transformer. |

| Type (1) | This model of shearer is available with headlights, cameras, methane monitoring, end displays and audible alarms. |

| Type (2) | All electrical material is designed and certified to IEC standards and also complies with other regional and national standards. |

| Type (1) | All hose and hosing is in compliance with guideline MDG 41 and MSHA regulations. |

| Type (2) | The hoses are assembled to Hose Assembly Standard DIN20066:201-10. |

| Type (3) | All hose assemblies are to ISO 6805 and proof tested to EN ISO 1402. |

| Type (1) | All hose assemblies are to ISO 6805 and proof tested to EN ISO 1402. |

| Type (2) | This shearer is available with onboard filtration, dust suppression spray bars, shearer clearers and ranging arm spray rings. |

| Type (3) | The hoses are assembled to Hose Assembly Standard DIN20066:201-10. |

| Type (1) | This system monitors oil levels and temperatures, flows, pressures and vibration. |

| Type (2) | A comprehensive health monitoring system is available. |

| Level of Automation (1) | State-based shearer automation “Navigator 2” |

| Level of Automation (2) | Zone-based automation “Navigator 1” |

| Level of Automation (3) | “Longwall Navigator” for improved face alignment and horizon control |

| Level of Automation (4) | Integrated longwall automation with “Navigator 2 + 3” |

| Type (1) | PMC Evo-S control system allows the shearer to be operated even if the overall control system is not functioning. |

| Type (10) | Its modular design allows it to be configured to meet individual control needs. |

| Type (2) | The shearer is equipped with a state-of-the-art industry PC in a flame-proof housing with plenty of computing power. |

| Type (3) | State-of-the-art industry PC allows flexibility to upgrade to future features such as condition monitoring. |

| Type (4) | Unlike competitor systems, modularity of the longwall system & control allows the longwall to operate in “fault-tolerant” mode. |

| Type (5) | In other words, integrated automation does not prevent control via individual PLC's in order to keep production up and running. |

| Type (6) | PMC Evo-S control system with state-of-the-art Ethernet communication and backup functionality. |

| Type (7) | This shearer has a state-of-the-art distributed automation system for the control, monitoring and protection of the shearer. |

| Type (8) | A Programmable Logic Controller (PLC) takes care of basic machine control tasks, ensuring that coal is produced. |

| Type (9) | Industry-leading Automation from the Pioneer of State-based Automation. |

| Type (1) | Transmission rating of 750 kW @ 37.4 rpm and above |

| Type (10) | Quillshaft transmission protection |

| Type (11) | Maximum oil capacity of 28 L (7 gal) in high speed compartment and 30 L (8 gal) in the epicyclic |

| Type (2) | Maximum drum diameter of 2500 mm (98 in) |

| Type (3) | Square drum hub (440 mm [17.3 in] across flats) |

| Type (4) | A robust cowl drive mechanism is also available on this model |

| Type (5) | Online vibration monitoring with VibraGuard |

| Type (6) | Available cutter motors - 500 kW, 620 kW and 750 kW, @ 50 Hz (800 hp, 1,000 hp and 1,200 hp, @ 60 Hz) |

| Type (7) | Choice of drum speeds |

| Type (8) | Complete with 32 mm (1.3 in) bore, through shaft PFF/PBF wet cutting |

| Type (9) | Integral monitoring transducers |

| Maximum Machine Speed | 28.56 m/min93.66 ft/min |

| Pull at Maximum Speed | 472.75 kN/106,278 lbf (48.40 tonnes/53.35 tons) |

| Speed at Maximum Pull | 14.28 m/min46.83 ft/min |

| Total Machine Pull | 945.51 kN/212,559 lbf (96.80 tonnes/106.70 tons) |

| Type (1) | Quillshaft transmission protection |

| Type (2) | Integral water cooling @ 9 L/min (2 gal/min) |

| Type (3) | Integral monitoring transducers |

| Type (4) | Maximum oil capacity of 25 L (7 gal) |

| Type (5) | Transmission reduction of 137:1 |

| Type (6) | Maximum power rating 125 kW (168 hp) |

| Type (7) | This unit has a haulage motor rating of 125 kW (168 hp) |

| Type (1) | Available with Machine Parking Brake |

| Type (2) | Available with Machine Position Encoder |

| Type (1) | Suitable for all current rack type systems |

| Type (2) | Transmission rating of 125 kW (168 hp) |

| Type (3) | Maximum haulage pull 945 kN (107 tons) |

| Type (4) | Innovative and unique downdrive design |

| Type (5) | Removable modular top drive wheel assembly (cartridge) |

| Type (6) | Downdrive ratio 17T—23T—10T (two wheel configuration) |

| Type (7) | Trapping shoe with replaceable wear inserts, safe and easy to replace (unique to Caterpillar) |

| Type (8) | Fully removable, rehandable, modular gearbox |

| Type (1) | Maximum protection of electrical boxes, providing the highest level of flameproof integrity |

| Type (2) | Improved access for maintenance and ease of overhaul and repair |

| Type (3) | Versatility of application due to fully modular construction |

| Type (4) | High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units |

| Type (5) | A split mainframe is available in case of transportation limitations |

| AFC Pan Width - Maximum | 1342 mm53 in |

| AFC Pan Width - Minimum | 1032 mm41 in |

| Clearance from Drum to AFC Toeplate | 300 mm12 in |

| Cutting Height - Maximum | 3930 mm155 in |

| Cutting Height - Minimum | 1800 mm71 in |

| Diameter - Shearer Cutting Drum | 1600 mm63 in |

| Distance Between Drums with Arms Horizontal | 14155 mm537 in |

| Distance Between Ranging Arm Hinge Points | 8525 mm336 in |

| Distance Between Trapping Shoe Centers | 6453 mm254 in |

| Height - Top of Machine Main Body | 1444 mm56.8 in |

| Machine Height - Over Main Body | 1444 mm56.8 in |

| Maximum Cutting Drum Overall Width | 1150 mm45.3 in |

| Ranging Arm Cutting Drum Diameter | 1600 mm63 in |

| Ranging Arm Length - Hinge to Drum | 2815 mm111 in |

| Shearer Drum Undercut of Floor | 619 mm24 in |

| Vertical Tunnel Clearance | 598 mm23.5 in |

| AFC Pan Width - Maximum | 1342 mm53 in |

| AFC Pan Width - Minimum | 1032 mm41 in |

| Clearance from Drum to AFC Toeplate | 300 mm12 in |

| Cutting Height - Maximum | 4135 mm163 in |

| Cutting Height - Minimum | 1900 mm75 in |

| Diameter - Shearer Cutting Drum | 1900 mm75 in |

| Distance Between Drums with Arms Horizontal | 14155 mm537 in |

| Distance Between Ranging Arm Hinge Points | 8525 mm336 in |

| Distance Between Trapping Shoe Centers | 6056 mm238 in |

| Height - Top of Machine Main Body | 1495 mm58.8 in |

| Machine Height - Over Main Body | 1495 mm58.8 in |

| Maximum Cutting Drum Overall Width | 1150 mm45.3 in |

| Ranging Arm Cutting Drum Diameter | 1900 mm75 in |

| Ranging Arm Length - Hinge to Drum | 2815 mm111 in |

| Shearer Drum Undercut of Floor | 718 mm28.3 in |

| Vertical Tunnel Clearance | 649 mm25.5 in |

| AFC Pan Width - Maximum | 1342 mm53 in |

| AFC Pan Width - Minimum | 1032 mm41 in |

| Clearance from Drum to AFC Toeplate | 300 mm12 in |

| Cutting Height - Maximum | 4360 mm172 in |

| Cutting Height - Minimum | 2200 mm87 in |

| Diameter - Shearer Cutting Drum | 2200 mm87 in |

| Distance Between Drums with Arms Horizontal | 14155 mm537 in |

| Distance Between Ranging Arm Hinge Points | 8525 mm336 in |

| Distance Between Trapping Shoe Centers | 6612 mm260 in |

| Height - Top of Machine Main Body | 1571 mm61.8 in |

| Machine Height - Over Main Body | 1571 mm61.8 in |

| Maximum Cutting Drum Overall Width | 1150 mm45.3 in |

| Ranging Arm Cutting Drum Diameter | 2200 mm87 in |

| Ranging Arm Length - Hinge to Drum | 2815 mm111 in |

| Shearer Drum Undercut of Floor | 793 mm31.2 in |

| Vertical Tunnel Clearance | 725 mm28.5 in |

| AFC Pan Width - Maximum | 1342 mm53 in |

| AFC Pan Width - Minimum | 1032 mm41 in |

| Clearance from Drum to AFC Toeplate | 300 mm12 in |

| Cutting Height - Maximum | 4570 mm180 in |

| Cutting Height - Minimum | 2500 mm98 in |

| Diameter - Shearer Cutting Drum | 2500 mm98 in |

| Distance Between Drums with Arms Horizontal | 14155 mm537 in |

| Distance Between Ranging Arm Hinge Points | 8525 mm336 in |

| Distance Between Trapping Shoe Centers | 6056 mm238 in |

| Height - Top of Machine Main Body | 1647 mm64.8 in |

| Machine Height - Over Main Body | 1647 mm64.8 in |

| Maximum Cutting Drum Overall Width | 1150 mm45.3 in |

| Ranging Arm Cutting Drum Diameter | 2500 mm98 in |

| Ranging Arm Length - Hinge to Drum | 2815 mm111 in |

| Shearer Drum Undercut of Floor | 866 mm34 in |

| Vertical Tunnel Clearance | 801 mm31.5 in |

| Coal Sizer | 100 kW134 HP |