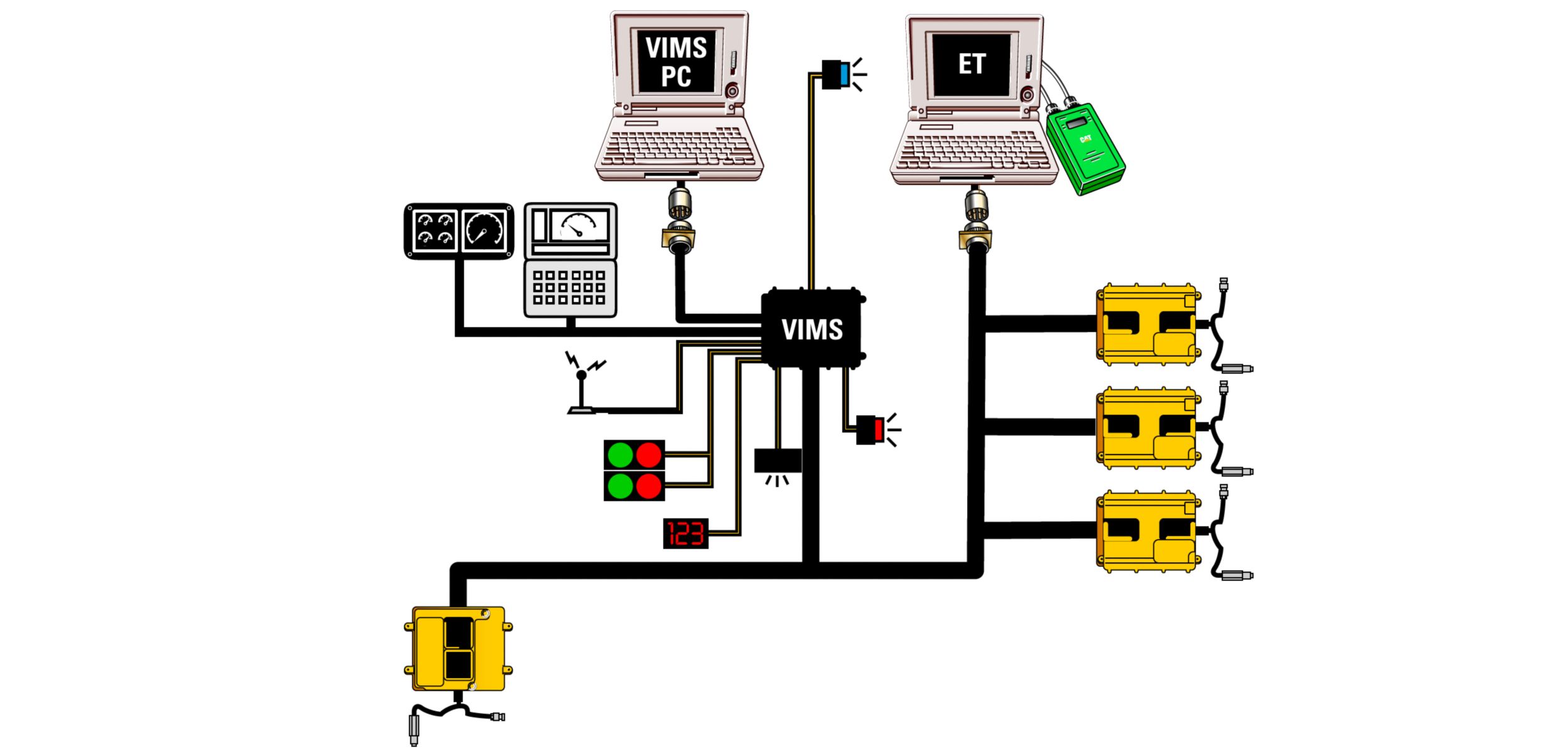

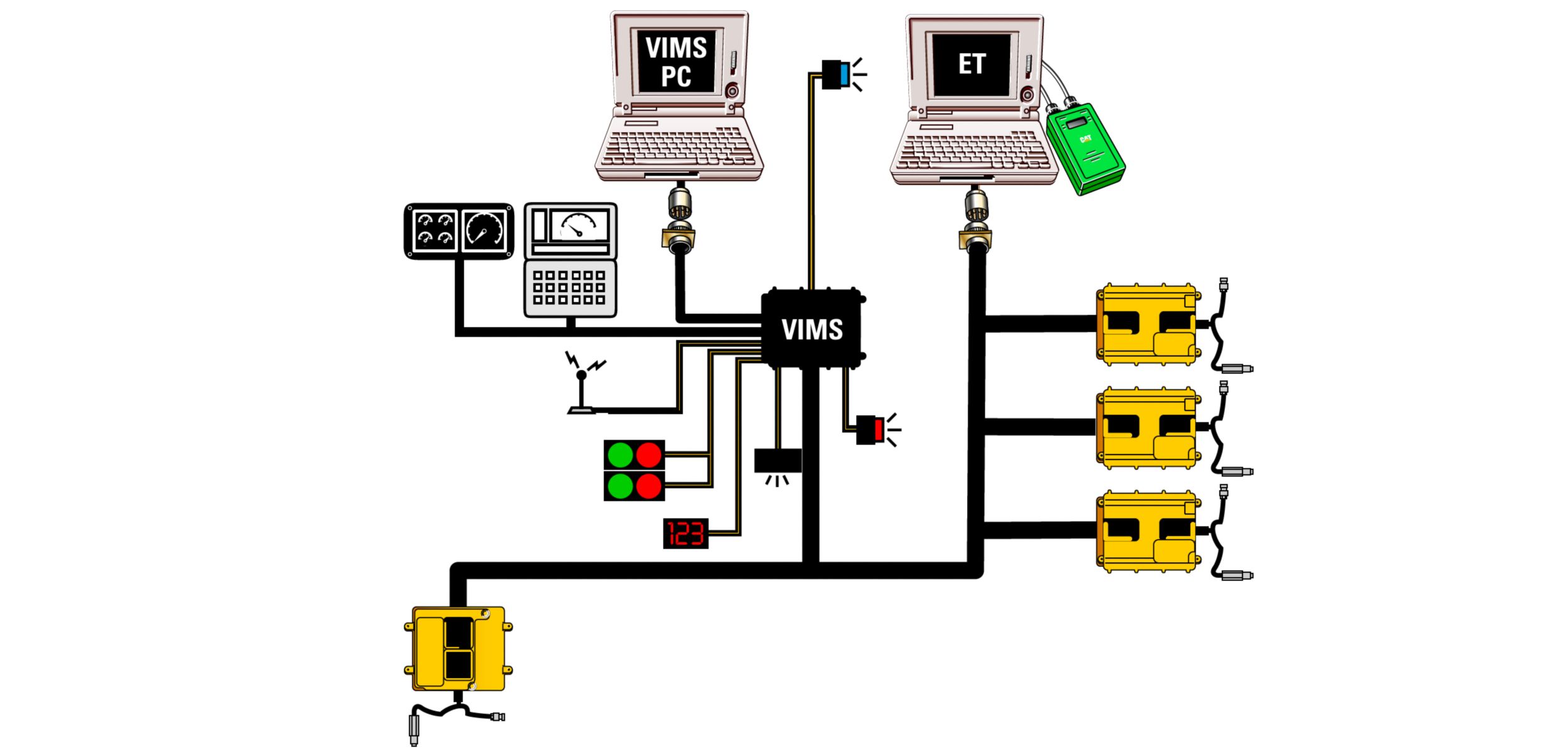

VIMS® Monitoring System -

The Caterpillar designed machine monitoring system provides critical machine health and payload information to the operator and service personnel. With the system monitoring and the advanced diagnostic ability, VIMS simplifies troubleshooting and reduces downtime by identifying abnormal conditions before they cause damage. VIMS also stores machine data to help manage production and utilize the efficiency Preventative Maintenance.

Production Management -

Production Management enhances truck/loading tool effectiveness, improves fleet productivity and helps extend the life of truck frames, tires, rims and power train components, while lowering operating and maintenance cost.

Payload Management -

Max Payload Speed Manager is a feature that aids in managing the Caterpillar 10/10/20 Overload Policy. Based on target payload weight and overload settings, the VIMS system logs and warns the operator when the truck reaches overload after second gear reweigh. The truck will be limited to second gear at 1,750 rpm, and the automatic retarder speed setting is reduced to 1,750 rpm until the load is dumped.

Road Analysis Control (RAC) -

Optional system monitors haul road conditions by measuring frame rack and pitch to improve haul road maintenance, cycle times, tire life and fuel efficiency.

VIMS-PC -

VIMS-PC, the off-board reporting software program, allows service personnel to download a complete record of machine health and productivity data to a laptop computer for diagnosis and analysis. Easy-to-use software enables service technicians and mine management to generate health and payload reports for more effective machine management.

VIMS Supervisor -

Optional software allows mine management to easily manage and interpret VIMS data for optimum fleet management and productivity.

Machine Management -

Service technicians or mine personnel can download data and generate reports. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, and lower operating costs.

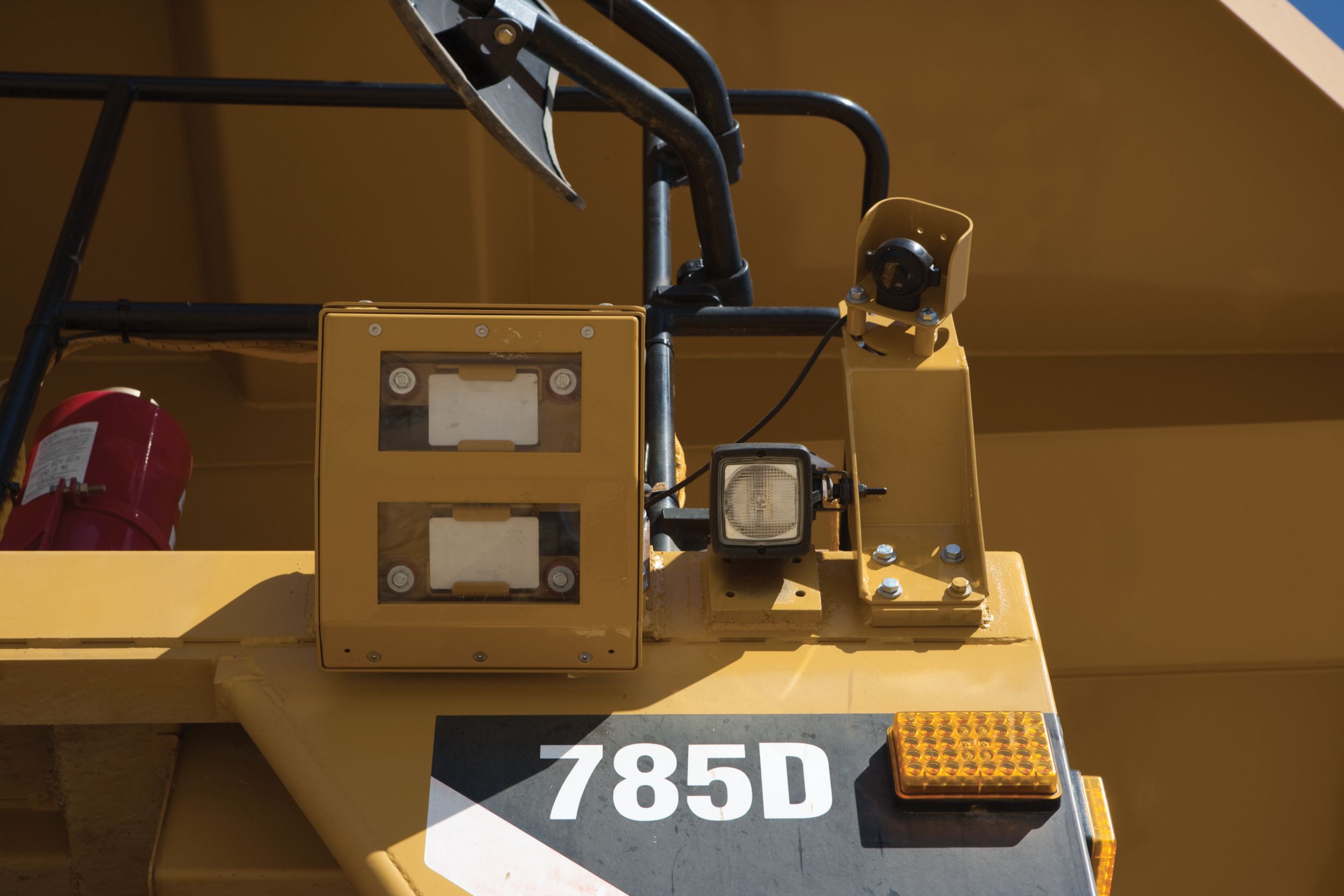

Gauge Cluster -

Conveniently located gauge cluster maintains a constant display of vital machine functions.