| Base Power (1st Gear) - Net | 93 kW125 HP |

| Gross Vehicle Weight - Typically Equipped | 13843 kg30519 lb |

| Blade Width | 3.7 m12 ft |

| Engine Model | Cat® C7 ACERT™ |

| Gross Vehicle Weight - Base - Total | 12133 kg26749 lb |

| Operating Weight - Typically Equipped | 30519 kg13843 lb |

| VHP - Gears 1-2, Net | 93 kW125 HP |

| VHP - Gear 3, Net | 101 kW135 HP |

| VHP - Gears 4-8, Net | 108 kW145 HP |

| VHP - Gears 1-2, Gross | 103 kW138 HP |

| VHP - Gear 3, Gross | 110 kW148 HP |

| VHP - Gears 4-8, Gross | 118 kW158 HP |

| Displacement | 7.2 l439 in³ |

| Bore | 105 mm4.1 in |

| Stroke | 127 mm5 in |

| Speed at Rated Power | 2000 r/min2000 r/min |

| Number of Cylinders | 6 |

| Derating Altitude | 3048 m10000 ft |

| High - Ambient Capability | 50 °C122 °F |

| Forward/Reverse Gears | 8 forward/6 reverse |

| Transmission | Direct drive, Powershift |

| Brakes - Service | Air actuated, multiple oil-disc |

| Brakes - Service - Surface Area | 18606 cm²2884 in² |

| Brakes - Parking | Air actuated, multiple oil-disc |

| Brakes - Secondary | Dual Circuit |

| Top Speed - Forward | 47.5 km/h29.5 mile/h |

| Top Speed - Reverse | 37.5 km/h23.3 mile/h |

| Turning Radius - Outside Front Tires | 7.3 m23.95 ft |

| Steering Range - Left/Right | 47.5 °47.5 ° |

| Articulation Angle - Left/Right | 20 °20 ° |

| Forward - 1st | 4.1 km/h2.5 mile/h |

| Forward - 2nd | 5.5 km/h3.4 mile/h |

| Forward - 3rd | 8 km/h5 mile/h |

| Forward - 4th | 11.1 km/h6.9 mile/h |

| Forward - 5th | 17.5 km/h10.8 mile/h |

| Forward - 6th | 23.7 km/h14.8 mile/h |

| Forward - 7th | 32.7 km/h20.3 mile/h |

| Forward - 8th | 47.5 km/h29.5 mile/h |

| Reverse - 1st | 3.2 km/h2 mile/h |

| Reverse - 2nd | 6 km/h3.7 mile/h |

| Reverse - 3rd | 8.7 km/h5.4 mile/h |

| Reverse - 4th | 13.8 km/h8.6 mile/h |

| Reverse - 5th | 25.8 km/h16 mile/h |

| Reverse - 6th | 37.5 km/h23.3 mile/h |

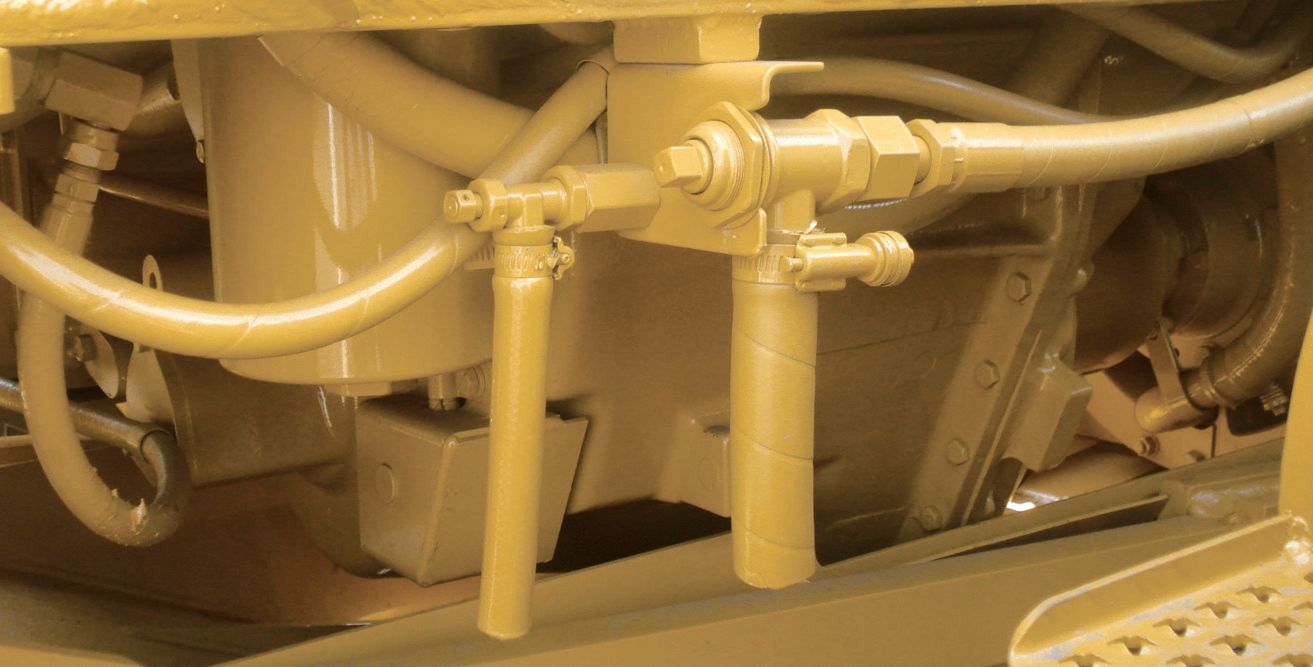

| Circuit Type | Load Sensing, Closed Center, PPPC |

| Pump Type | Variable Piston |

| Maximum System Pressure | 25500 kPa3699 psi |

| Standby Pressure | 3600 kPa522.1 psi |

| Reservoir Tank Capacity | 24.5 l6.5 gal (US) |

| VHP Range - Net | 93-108 kW (125-145 hp) |

| Moldboard - Height | 610 mm24 in |

| Moldboard - Thickness | 22 mm0.9 in |

| Arc Radius | 413 mm16.3 in |

| Throat Clearance | 58 mm2.3 in |

| Cutting Edge Width | 152 mm6 in |

| Cutting Edge Thickness | 16 mm0.6 in |

| End Bit - Width | 152 mm6 in |

| End Bit - Thickness | 16 mm0.6 in |

| Blade Pull - Maximum GVW | 10623 kg23420 lb |

| Down Pressure - Maximum GVW | 9317 kg20540 lb |

| Circle Centershift - Right | 656 mm25.8 in |

| Circle Centershift - Left | 658 mm25.8 in |

| Moldboard Sideshift - Right | 663 mm26 in |

| Moldboard Sideshift - Left | 512 mm20.2 in |

| Maximum Blade Position Angle | 90 °90 ° |

| Blade Tip Range - Forward | 40 °40 ° |

| Blade Tip Range - Backward | 5 °5 ° |

| Maximum Shoulder Reach Outside of Tires - Right | 1928 mm75.9 in |

| Maximum Shoulder Reach Outside of Tires - Left | 1764 mm69.4 in |

| Maximum Lift Above Ground | 410 mm16.1 in |

| Maximum Digging Depth | 775 mm30.5 in |

| Ripping Depth - Maximum | 262 mm10.3 in |

| Ripper Shank Holders, Quantity | 5 |

| Ripper Shank Holder Spacing | 533 mm21 in |

| Penetration Force | 4083 kg9001 lb |

| Pry-Out Force | 2108 kg4648 lb |

| Machine Length Increase, Beam Raised | 1058 mm41.7 in |

| Mid, V-Type - Working Width | 1184 mm46.6 in |

| Mid, V-Type - Scarifying Depth, Maximum | 229 mm9 in |

| Mid, V-Type - Scarifier Shank Holders Quantity | 11 |

| Mid, V-Type - Scarifier Shank Holder Spacing | 116 mm4.6 in |

| Base Power (1st Gear) - Net - Metric | 93 kW127 HP |

| Fan Speed Maximum | 1575 r/min1575 r/min |

| Maximum Torque - Net | 774 N·m571 ft-lb |

| Note (1) | Net power is tested per ISO 9249, SAE J1349, and EEC 80/1269 standards in effect at the time of manufacture. |

| Note (2) | Net power advertised is the power available at rated speed of 2,000 rpm, measured at the flywheel when engine is equipped with fan, air cleaner, muffler and alternator. |

| Note (3) | Maximum torque measured at 1,000 rpm in gears 4-8. |

| Front-Section Modulus - Maximum | 3681 cm³225 in³ |

| Front-Section Modulus - Minimum | 1619 cm³99 in³ |

| Gross Vehicle Weight | 17000 kg37478 lb |

| Note (1) | Pump output measured at 2,150 rpm. |

| Optional High Output Pump | 210.5 l/min55.6 gal/min |

| Pump Output - Standard Pump | 159.1 l/min42 gal/min |

| Blade Pull - Base GVW | 8112 kg17884 lb |

| Down Pressure - Base GVW | 5594 kg12332 lb |

| Note (1) | Blade Pull calculated at 0.9 traction coefficient, which is equal to ideal no-slip conditions, and Gross Vehicle Weight (GVW). |

| Note (1) | Maximum travel speeds calculated at high idle on standard machine configuration with 14.00-24 12PR (G-2) tires. |

| Note (1) | Brakes meet the following standards: SAE J/ISO 3450 JAN98. |

| Note (1) | Ripper tow package. |

| Note (1) | The mid-mount scarifier is positioned under the drawbar between the moldboard and front axle. |

| Note (1) | These standards are met when the machine is equipped with a cab. |

| Note (2) | The static operator sound pressure level is 77 dB(A) when “ISO 6394:2008” is used to measure the value for an enclosed cab. The measurement was conducted with the cab doors and the cab windows closed. The cab was properly installed and maintained. |

| Gross Vehicle Weight - Maximum - Total | 17000 kg37478 lb |

| Gross Vehicle Weight - Typically Equipped - Front Axle | 3970 kg8751 lb |

| Gross Vehicle Weight - Typically Equipped - Rear Axle | 9873 kg21768 lb |

| Gross Vehicle Weight - Typically Equipped - Total | 13843 kg30519 lb |

| Note (1) | Base weight calculated on standard machine configuration with 13.00-24 12PR (G-2) tires, SP rims, full fuel tank, coolant, lubricants and 90 kg (198 lb) operator. |

| Note (2) | Typical operating weight calculated on standard machine configuration with HVAC ROPS cab, 13.00-24 12PR (G-2) tires, MP rims, MMS, hydraulic tip, full fuel tank, coolant, lubricants and 90 kg (198 lb) operator. |

| Gross Vehicle Weight | 13843 kg30519 lb |

| Circle - Diameter | 1530 mm60.2 in |

| Circle - Blade Beam Thickness | 30 mm1.2 in |

| Drawbar - Height | 127 mm5 in |

| Drawbar - Width | 76.2 mm3 in |

| Front Axle - Height to Center | 615 mm24.2 in |

| Front Axle - Wheel Lean - Left/Right | 18 °18 ° |

| Front Axle - Total Oscillation per Side | 32 °32 ° |

| Front-Top/Bottom Plate - Width | 280 mm11 in |

| Front-Top/Bottom Plate - Thickness | 22 mm0.9 in |

| Front-Side Plates - Width | 236 mm9.3 in |

| Front-Side Plates - Thickness | 10 mm0.4 in |

| Front-Linear Weights - Minimum | 134 kg/m90 lb/ft |

| Front-Linear Weights - Maximum | 172 kg/m115 lb/ft |

| Height | 438 mm17.24 in |

| Width | 172 mm6.77 in |

| Sidewall Thickness - Inner | 1 mm1 in |

| Sidewall Thickness - Outer | 16 mm0.63 in |

| Drive Chain Pitch | 44.5 mm1.75 in |

| Wheel Axle Spacing | 1510 mm59.45 in |

| Tandem Oscillation - Front Up | 15 °15 ° |

| Tandem Oscillation - Front Down | 25 °25 ° |

| Fuel Capacity | 305 l80.6 gal (US) |

| Cooling System | 40 l10.6 gal (US) |

| Engine Oil | 18 l4.8 gal (US) |

| Transmission - Differential - Final Drives | 48 l12.7 gal (US) |

| Tandem Housing - Each | 49 l12.9 gal (US) |

| Front Wheel Spindle Bearing Housing | 0.5 l0.1 gal (US) |

| Circle Drive Housing | 7 l1.9 gal (US) |

| Gross Vehicle Weight - Base - Front Axle | 3120 kg6878 lb |

| Gross Vehicle Weight - Base - Rear Axle | 9013 kg19871 lb |

| Gross Vehicle Weight - Maximum - Front Axle | 5197 kg11456 lb |

| Gross Vehicle Weight - Maximum - Rear Axle | 11803 kg26022 lb |

| Height - ROPS Cab | 3326 mm131 in |

| Height - Non-ROPS Cab | 3321 mm130.7 in |

| Height - ROPS/Canopy | 3326 mm131 in |

| Ground Clearance - Center Front Axle | 602 mm23.7 in |

| Length - Between Tandem Axles | 1510 mm59.4 in |

| Length - Front Axle to Moldboard | 2598 mm102.3 in |

| Length - Front Axle to Mid Tandem | 5870 mm231.1 in |

| Length - Front Tire to Rear of Machine | 8265 mm325.4 in |

| Length - Counterweight to Ripper | 9769 mm384.6 in |

| Ground Clearance - Trans. Case | 341 mm13.4 in |

| Height - Top of Cylinders | 2885 mm113.6 in |

| Height - Exhaust Stack | 2865 mm112.8 in |

| Width - Tire Center Lines | 2056 mm80.9 in |

| Width - Outside Rear Tires | 2439 mm96 in |

| Width - Outside Front Tires | 2449 mm96.4 in |

| ROPS/FOPS | ISO 3471:1994/ISO 3449:2005 |

| Steering | ISO 5010:2007 |

| Brakes | ISO 3450:1996 |

| Sound | ISO 6394:2008/ISO 6396:2008 |

| Torque Rise | 50 %50 % |